Page 25 of 37

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

• Remove deposits of tyre powder and other waste

materials with a vacuum cleaner.

DO NOT BLOW IT WITH COMPRESSED AIR.

• Do not use solvents to clean the pressure regulator.

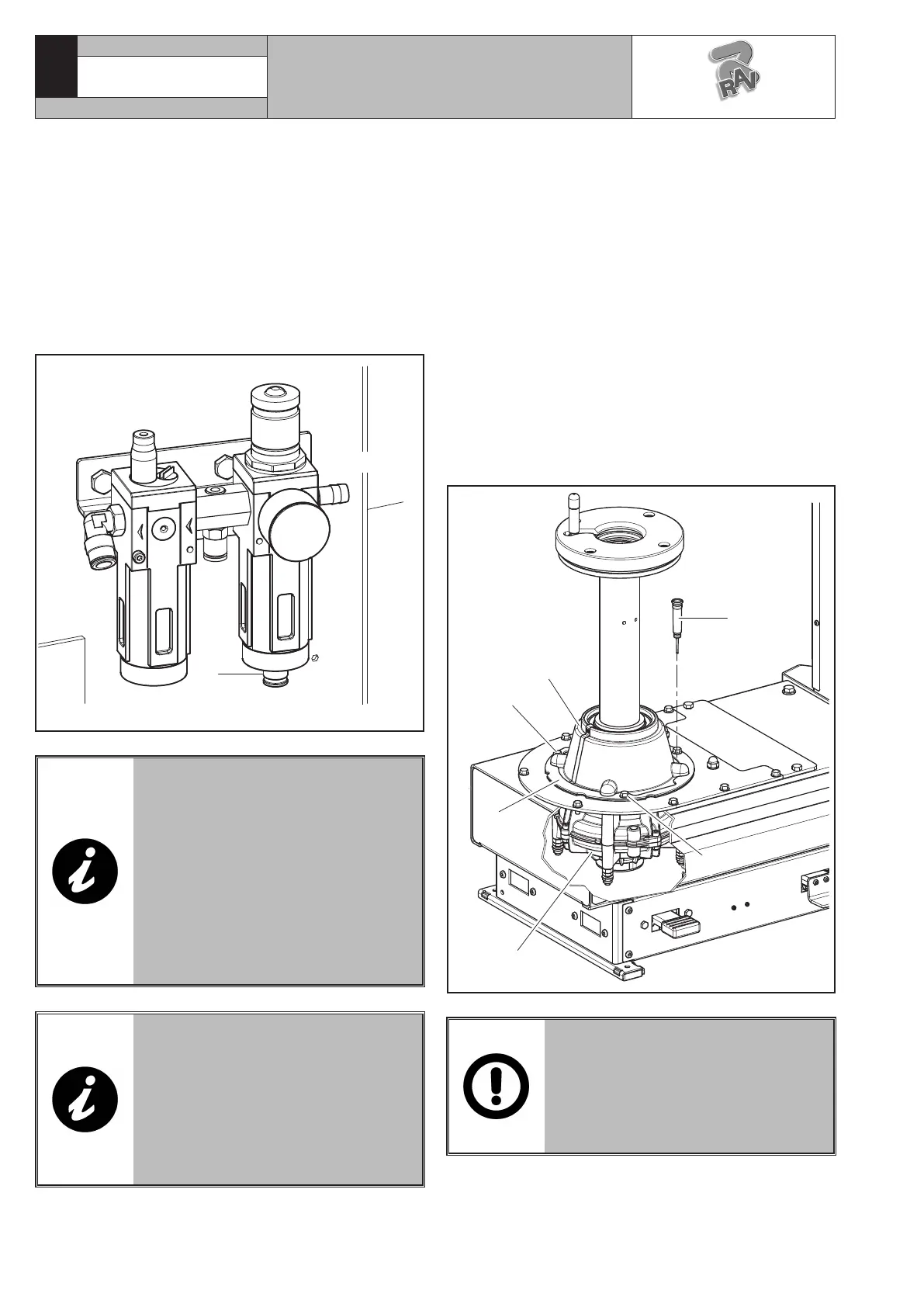

• The conditioning unit is equipped with an automatic

vacuum-operated drain therefore it requires no

manual intervention by the operator (see Fig._44).

• Periodically check the calibration of the lubricator

of the pressure regulator/oiler unit: 1 oil drop every

11-15 revolutions of self-centring chuck motor.

1

PRESSURE REGULATOR

DEPRESSURE RELEASE

SEMI-AUTOMATIC

OILER

AIR

SUPPLY

Fig. 44

IN ORDER TO ENSURE A GOOD

FUNCTIONING AND TO AVOID THE

PRESENCE OF CONDENSATION

IN THE AIR TREATMENT UNITS

WITH SEMI-AUTOMATIC DRAIN,

IT'S NECESSARY TO MAKE SURE

ABOUT THE CORRECT POSITION

OF THE VALVE (FIG. 44 REF. 1),

PLACED UNDER THE CAP. TO

ACTIVATE A CORRECT DRAIN

FUNCTION, THE CAP MUST BE

ROTATED IN THE RIGHT WAY.

IN ORDER TO ALLOW A LONGER

LIFE OF THE FILTER AND OF ALL

MOVING PNEUMATIC DEVICES,

YOU HAVE TO MAKE SURE THAT

THE SUPPLIED AIR IS:

• EXEMPT FROM THE LUBRICAT-

ING OIL OF THE COMPRESSOR;

• EXEMPT FROM HUMIDITY;

• EXEMPT FROM IMPURITY.

• Periodically, with a frequency of at least once a month,

lubricate the arms of the bead breaking roller and

of the tools.

• Immediately replace worn parts, bead breaking roller,

assembly tools.

• Every week and/or when necessary, top up the oil

tank using the filler hole provided, closed by a cap

or screw, on the lubricator filter.

NOTE: This operation should not be carried out

by unscrewing the cup of the lubricator filter.

• The use of synthetic oil might damage the pressure

regulator filter.

• Immediately replace worn parts, bead breaking roller,

assembly tool.

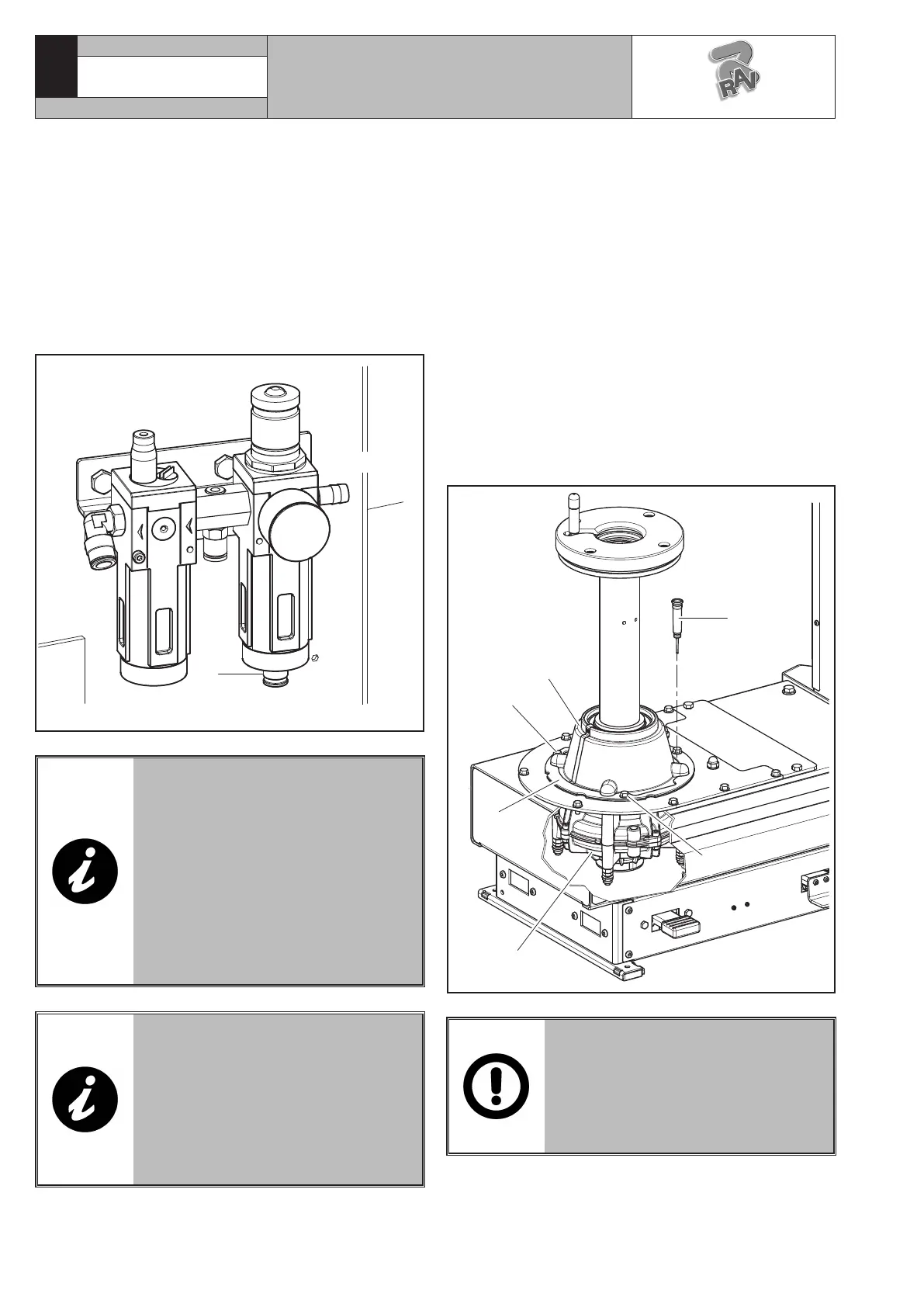

• Periodically (at least every 100 working hours) check

reduction gear lubricating oil level (Fig. _45 ref._5).

Such operation must be effectuated unscrewing the

screws (Fig._45 ref._1), removing the flange (Fig._45

ref. _2), the guard (Fig._45 ref._3) and the plug

(Fig._45 ref. _4) on the reduction gear.

1

4

5

1

2

3

Fig. 45

ANY DAMAGE TO THE MACHINE

DEVICES RESULTING FROM THE

USE OF LUBRICANTS OTHER

THAN THOSE RECOMMENDED

IN THIS MANUAL WILL RELEASE

THE MANUFACTURER FROM ANY

LIABILITY!!

7105-M002-10_R

RAVAGLIOLI S.p.A.

G1180.30SLIM - G1180.30SLIMIT

Loading...

Loading...