nne

co

er tu

e gas

o

ers

water

eaters –

o

er

anua

16

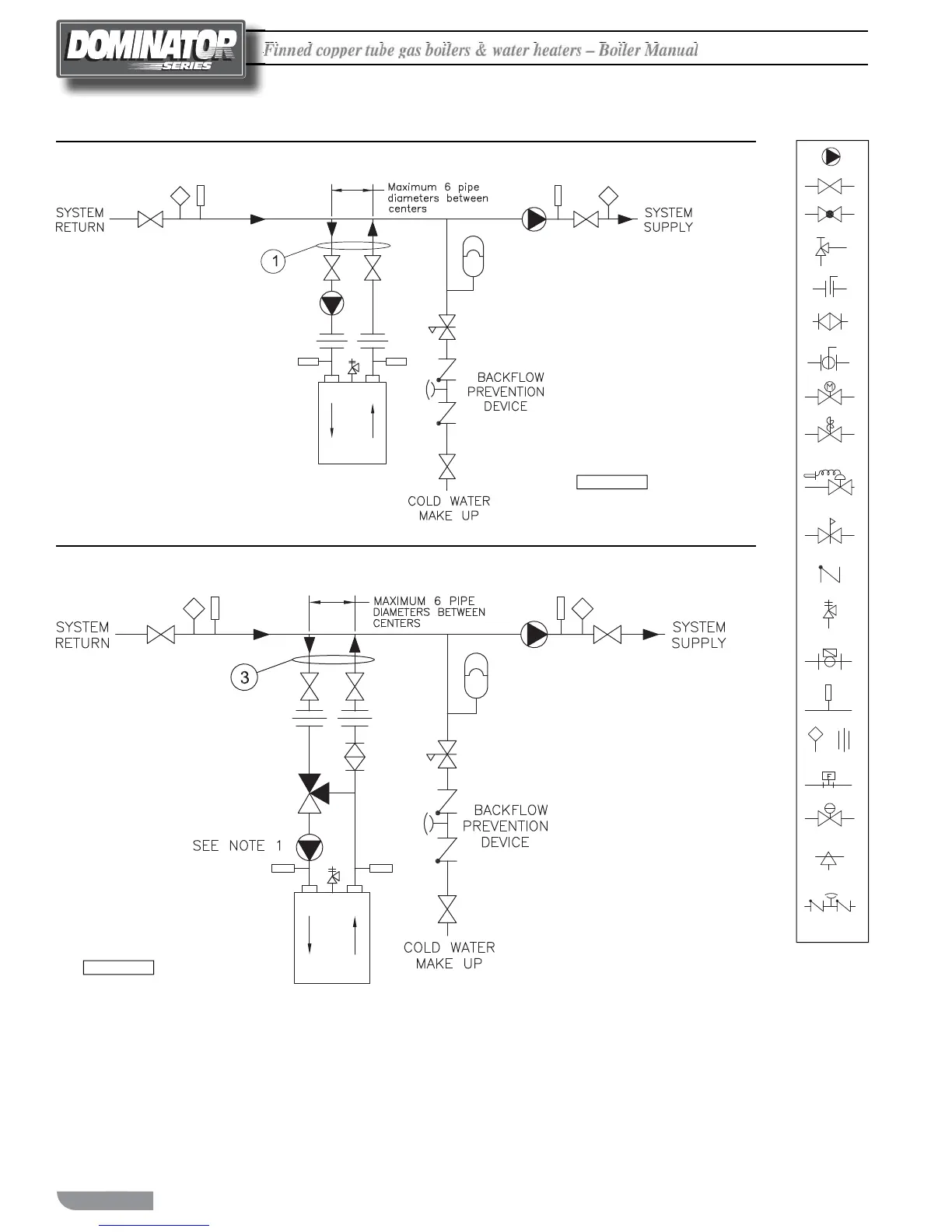

Figure 11 Typical Primary/Secondary Piping

(See Notes)

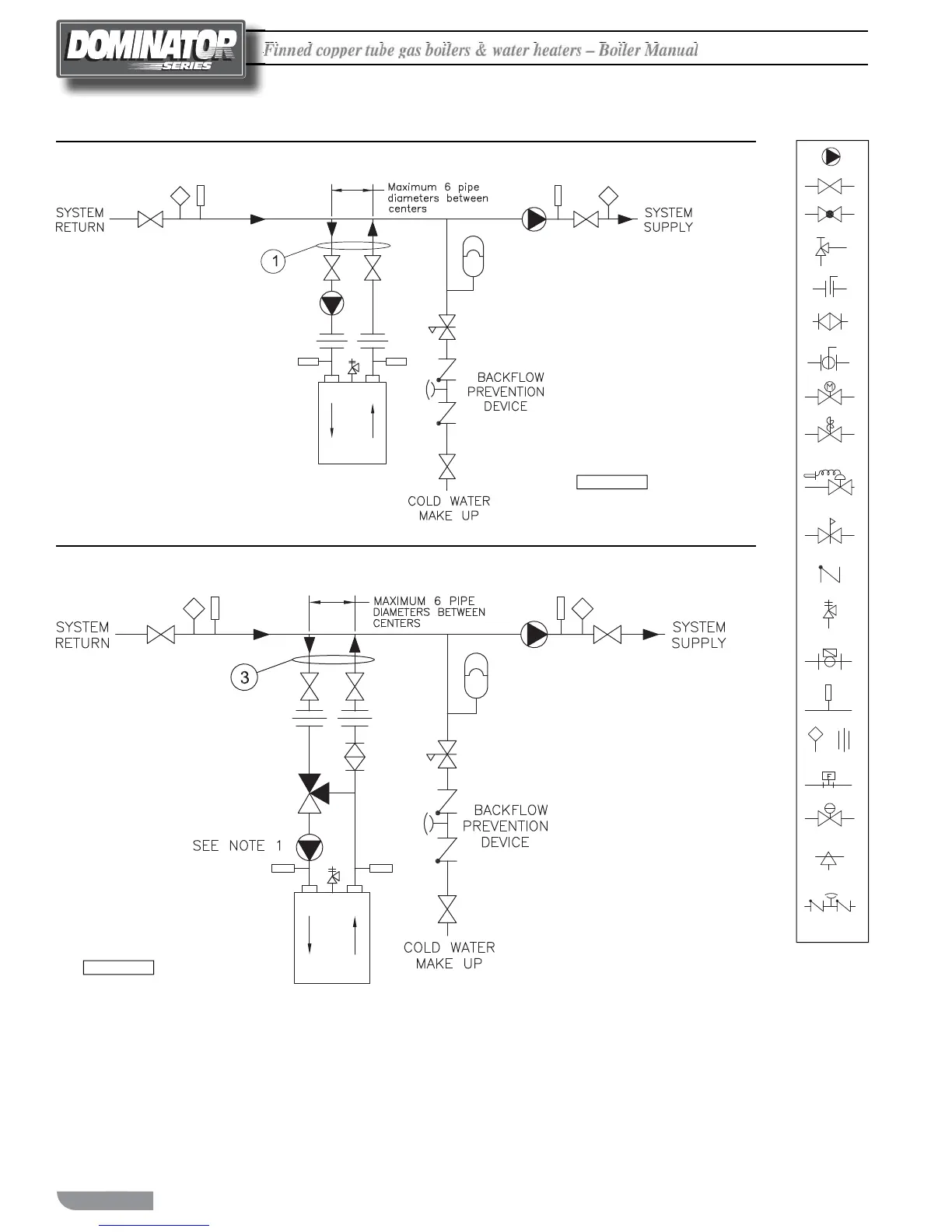

Figure 12 Low Temperature Piping with Thermostatic Valve

(See Notes)

Operated Valve

Air Vent

Pressure Switch

Aquastat Union

Gas Pressure

Regulator

Automatic

Thermometer

Flow Switch

Pressure

Relief Valve

Reducing Valve

Self-Operated

Check Valve

Pressure

Va lve

Pump

Motorized Valve

Solenoid

Ball Valve

Bufferfly Valve

Angle Valve

Gate Valve

Globe Val ve

Balance Valve

Backflow-

Prevention

Device

H-1 Rev 3

NOTES:

1. Boiler circuit piping must be sized

large enough to handle maximum ow

through unit.

2. Boiler pump sized to boiler design ow

requirements.

3. All boilers furnished with factory mount-

ed outlet water temperature gauge.

4. Boiler pump purging required. Use termi-

nals supplied.

Notice: These drawings show suggested pip-

ing con guration and valving.

Check with local codes and ordinances for

speci c requirements.

H-18 Rev 2

NOTES:

1. For pump selection consult factory.

2. Boiler pump sized to boiler and thermostatic 3-way valve design ow

requirements.

3. Boiler circuit piping must be sized large enough to handle maximum ow

through unit.

4. All boilers furnished with factory mounted outlet water temperature gauge.

5. Boiler pump purging required. Use terminals supplied.

6. Valve is precalibrated for 140°F return temperature.

Notice: These drawings show suggested piping con guration and valving. Check

with local codes and ordinances for speci c requirements.

Loading...

Loading...