nne

co

er tu

e gas

o

ers

water

eaters –

o

er

anua

24

BOILER/WATER HEATER OPERATION

Staging Operation

e Dominator boiler/water heater series is separated into 2-stage

and 4-stage units depending on the model size. e 300 through 2100

models have two ring inputs. e 1050 through 2100 have four.

Input staging is controlled from the staging controller that signals the

relay board to select the blower and gas valve modes. Table 12

identi es the stages and ring modes associated with the 2 stage units

(D300-D2100), and Table 13 identi es the stages and ring modes

associated with the 4 stage units (D1050-D2100).

Table 12 Firing Modes (D300-D2100)

Stage Left Firing Mode

Off Off

1 Low Fire

2 High Fire

Table 13 Firing Modes (D1050-D2100)

Stage Left Firing Mode Right Firing Mode

Off Off Off

1 Low Fire Off

1

2 Low Fire Low Fire

3 High Fire Low Fire

4 High Fire High Fire

1- The left main valve will operate at low fi re, but left and right

blowers will be on and operating at low fi re (low speed).

e outlet water temperature is automatically controlled by the

staging controller. It utilizes inputs from the inlet and outlet water

temperature sensors, plus optional tank and outside sensors, to stage

the boiler/water heater. e Dominator will stage up or down

progressively, but will not jump over a stage. Stage 1 will operate rst,

last and whenever the boiler/water heater is in operation. Consult

the staging controller documentation for further information on

controller operation.

For the D1050-D2100, the air inlet plenum is divided into

le and right sides. A separate blower, main gas valve and manifold

are used for each side. However, the combustion chamber is

undivided. For best overall performance, gas and air ows should be

balanced so that when both sides are at low or high re, stage 2 or 4,

the gas and air ows are equal.

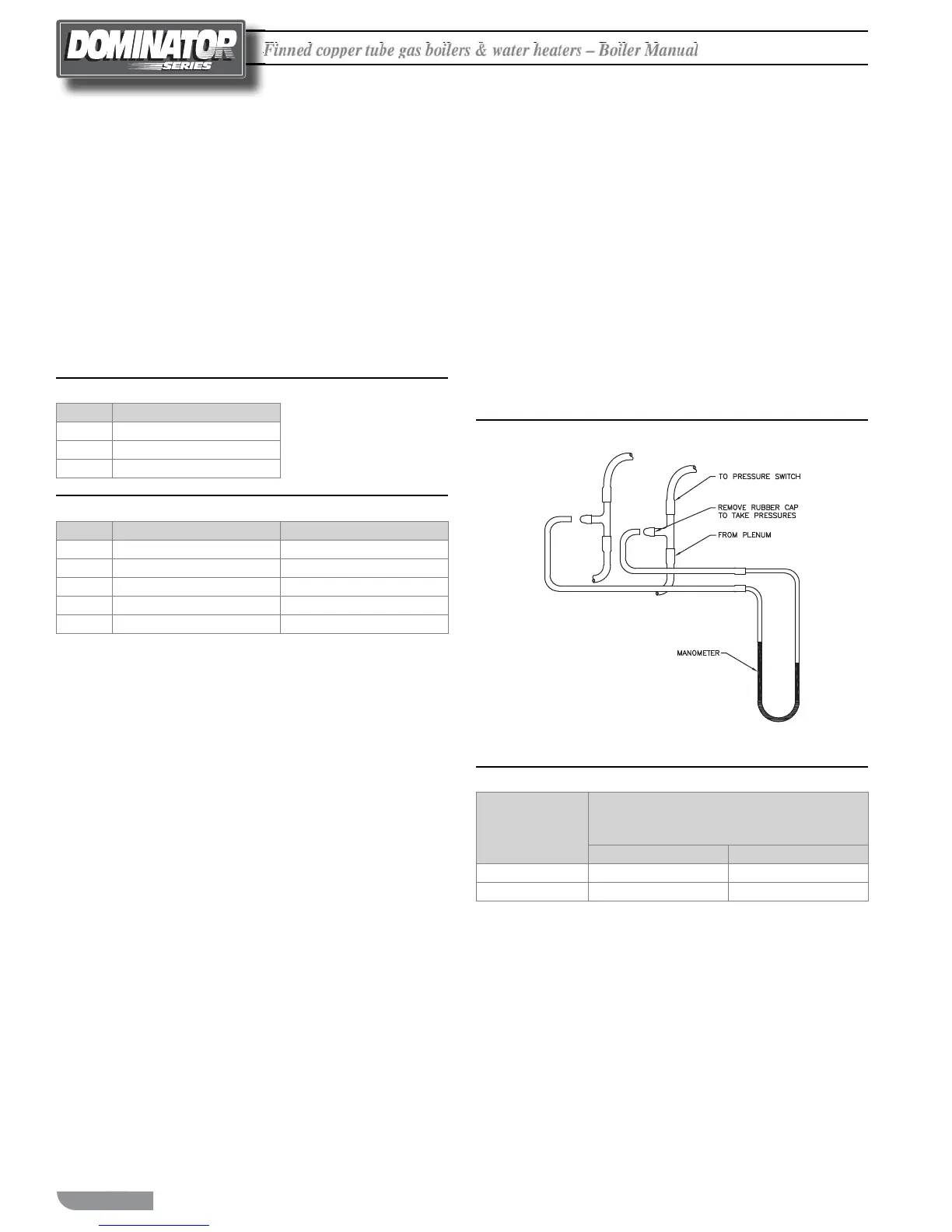

Pressure Switch Settings

Di erential pressure switches are provided in the Dominator to shut

down gas ow under a blocked ue or inlet condition. One low re

and one high re pressure switch are used for the 300 through 900

models. Two low re and two high re pressure switches are used

for the 1050 through 2100 models. e low re pressure switches

serve to shut down gas ow if there is a blocked ue or inlet condition

during low re operation. Similarly, the high re switches will shut

down gas ow if there is a blocked ue or inlet condition during high

re operation. e di erential pressure is taken between the

air plenum and the pressure inside one of the main burners.

Pressure taps are provided in the control compartment for taking

the di erential pressure readings, Figure 17. Table 14 lists the

di erential pressure se ings for all of the models.

Figure 17 Pressure Switch Tap(s)

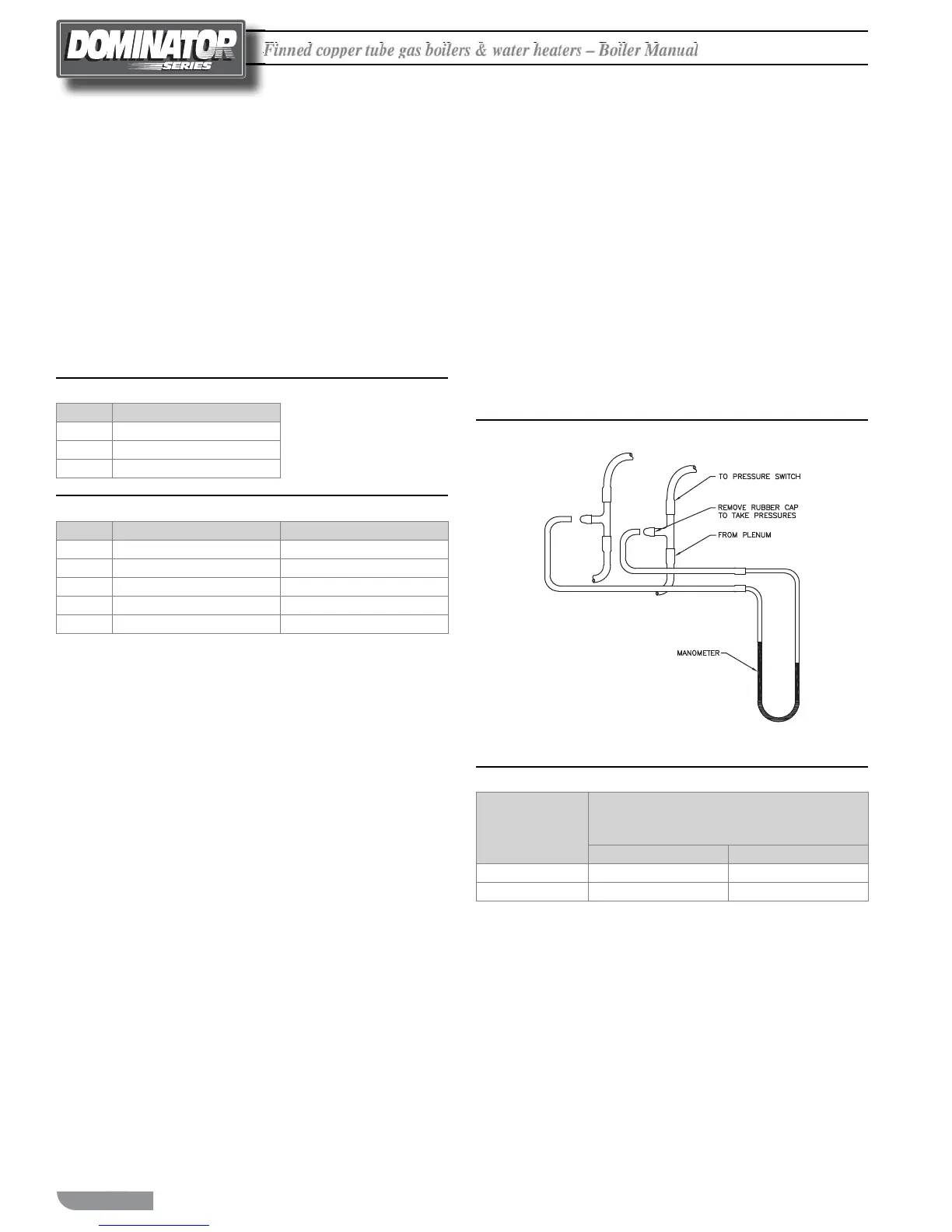

Table 14 Differential Pressure Settings (All Units)

Model

Differential Pressure

Requirement at High Fire

(All Units)

Inches W.C.

mm W.C.

300-900

1.0 ± 0.1

20.3 ± 2.5

1050-2100

1.0 ± 0.1

25.4 ± 2.5

Loading...

Loading...