Installation

3. Mark the hole positions. Drill and tap 2

holes M8 to attach the sensor bracket,

and 2 holes M6 in the lift arm for the

magnet bracket*.

* In some cases the magnet can be

mounted directly onto the lift arm but

you must fit a fibre washer between

the magnet and the arm.

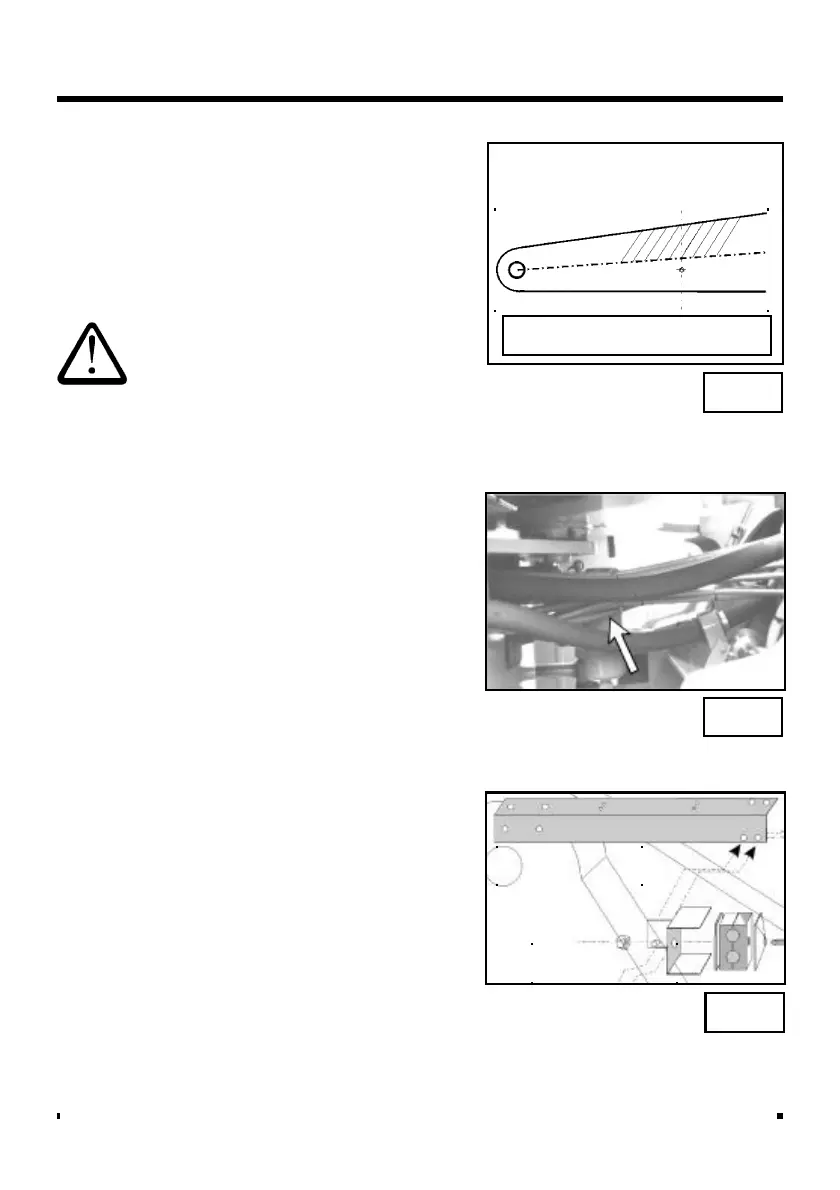

Do not drill the lift arm above the

center line (neutral axis) of the lift

arm ! (fig. 11)

4. Fit the brackets. Attach the magnet

using the stainless steel setscrew with

the fibre washer between the magnet

and mounting face.

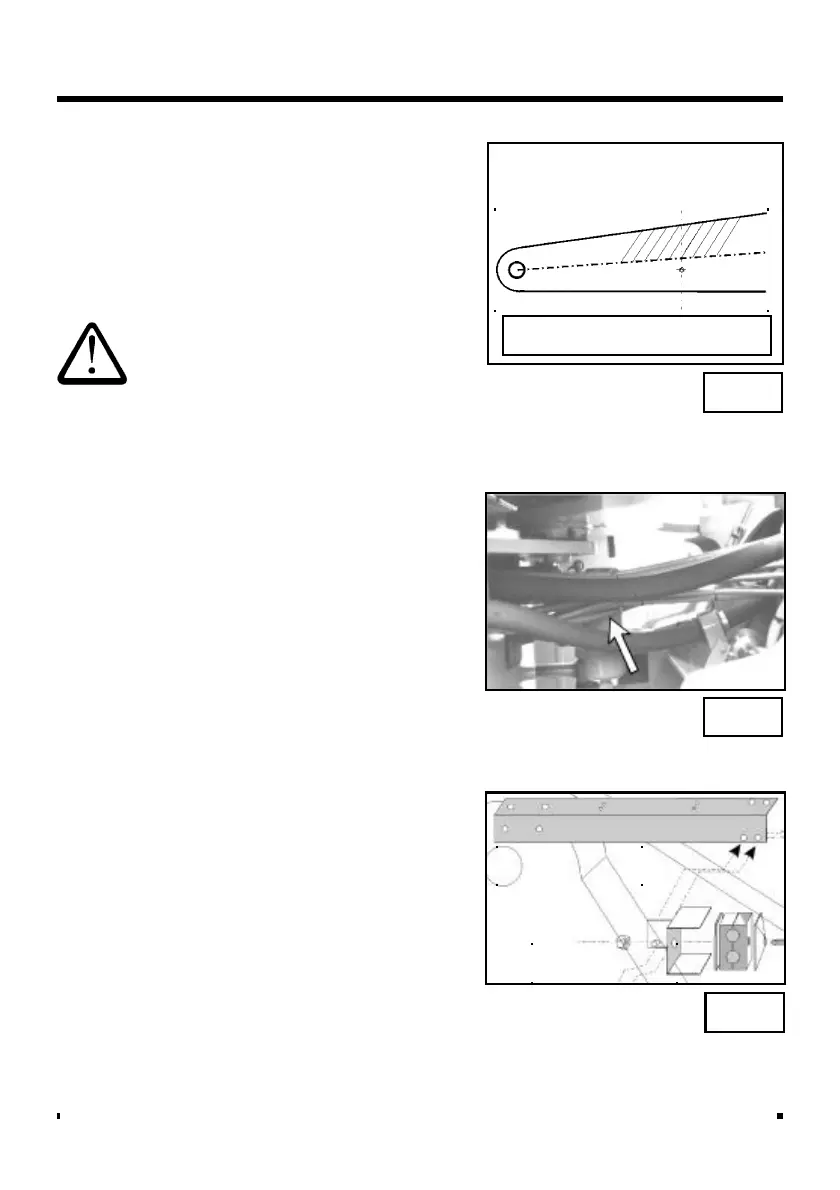

5. Route all cables through the conduit

provided in the kit. Cable tie the

conduit at 300mm (12") spacing

following where possible existing

pipework or cabling. You must pass

the conduit through the chassis pivot

point on articulated loaders (fig. 12).

Do not secure the cables to the

vehicle loom.

6 Assemble the reference and direction

clamp assembly as shown in figure 13.

The bracketing is designed so that the

assembly may be installed to either

side of the machine, by rotating the

angle bracket 90 degrees.

Remove the original M8 bolt from the

green Nylon Clamp, and replace it

with the longer M8 x 60 mm, Then

tighten with the sensors in the correct

position.

The clamp with sensors should then

be inserted into the clamp holder, and

tightened into position by using the

M8 nyloc nut supplied.

Fig. 12

Fig. 11

Do not drill above center line!

Fig. 13

Angle Bracket

Clamp Holder

Loading...

Loading...