Installation

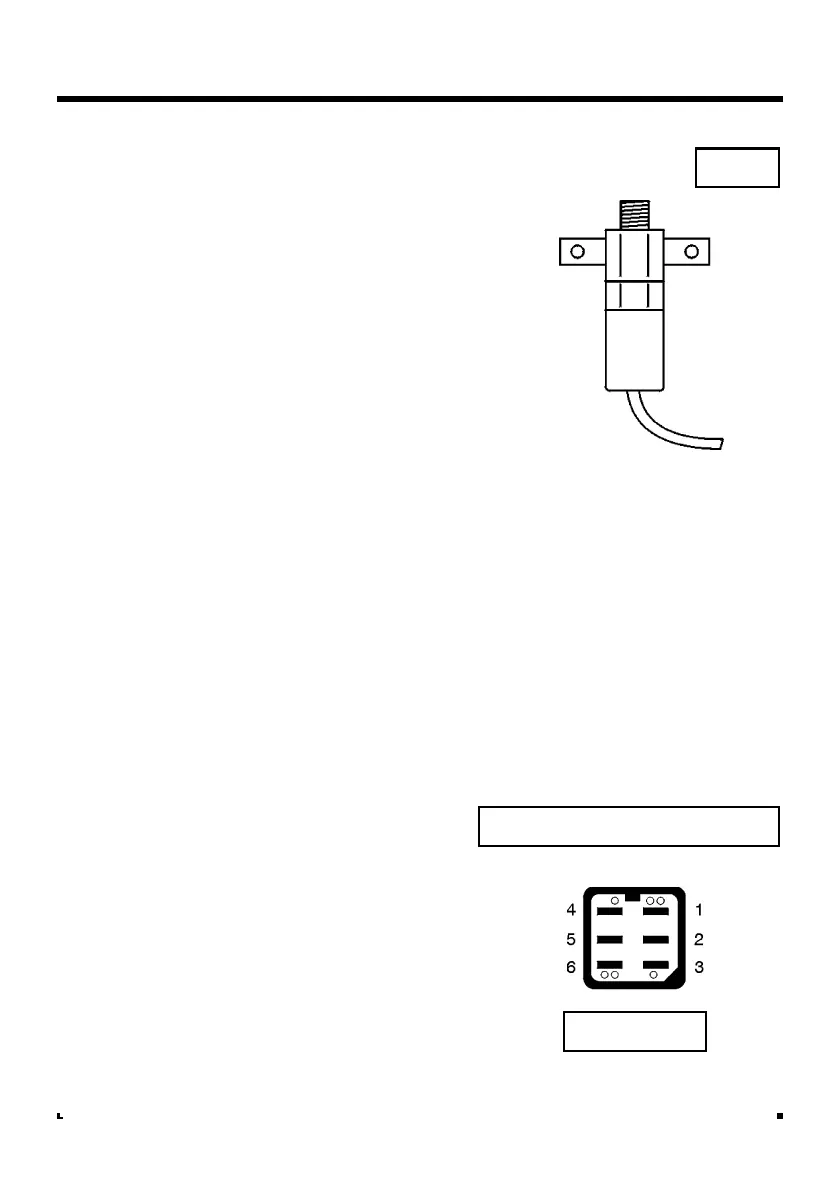

Load Sensor mounting

6. Connect the hydraulic hose to the tee

fitting and route the hose towards the

back of the loader frame. Connect to

the load sensor and mount the sensor

in a well protected position where it

can be easily reached for servicing.

7. With the bucket a few inches off the

ground, gently slacken the hose

connection at the load sensor to bleed

off any air inside.

NOTE: Mount the pressure sensor in a well

protected area, in an upside down

position (fig 6b). This helps prevent air

bubbles hitting and damaging the

diaphragm of the sensor.

Load Sensor connection

7. Connect the extension cable to the

"Weatherpak" connector on the sensor

lead and route inside conduit back to

the Harting connectors.

Cable-tie the conduit securely to

existing hydraulic lines or conduits.

Avoid coiling excess cable - it is best

practice to cut the cable to the

required length and re-crimp.

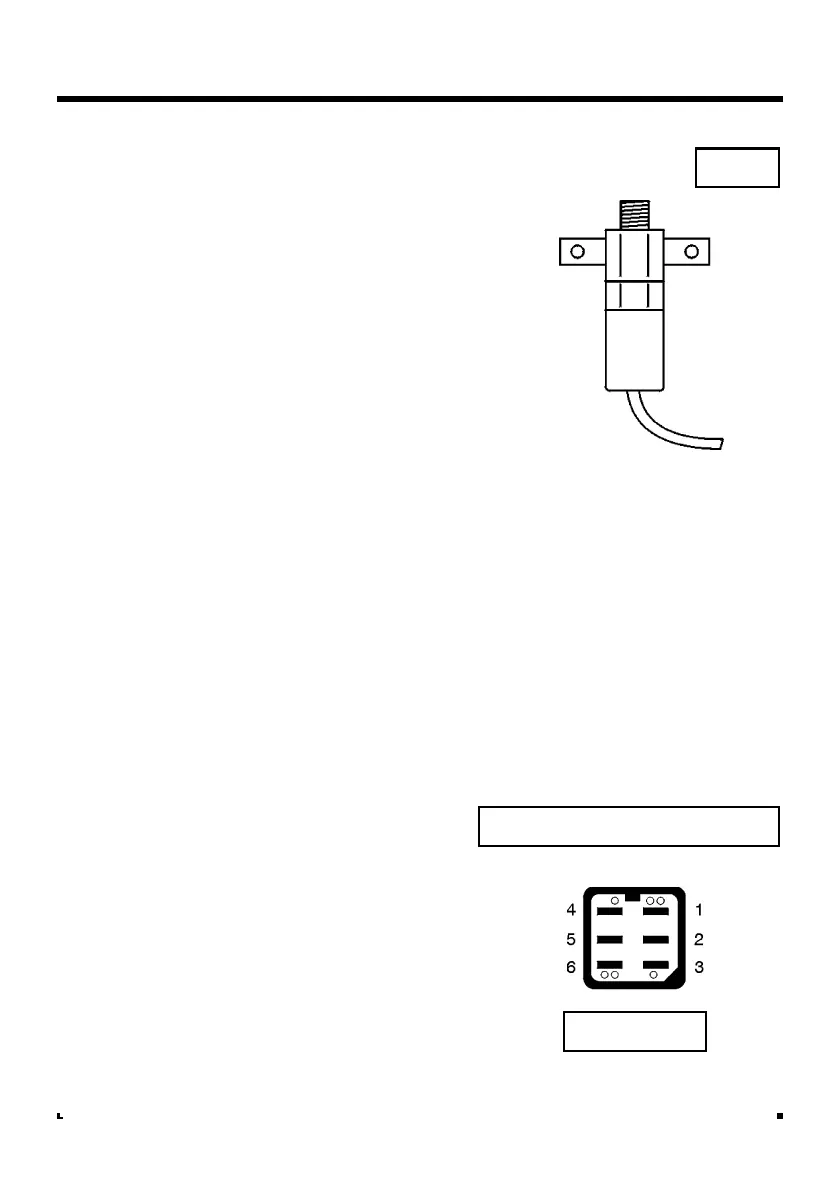

8. Connect to the GRAY Harting connec-

tor as follows (fig. 7):-

Colour Function Terminal #

Red +V GRAY 4

Blue 0V GRAY 1

Green Signal GRAY 5

NOTE: There is no provision for strain relief on

these connections. It is recommended

that sensor cables are cable-tied

securely out of the way.

Fig. 7 : Load Sensor Connections

Fig. 6b

Red - +V

Blue - 0V

Green - Signal

Gray Harting

Loading...

Loading...