10

INSTALLATION

The unit is equipped with a universal mounting foot for attachment to standard DIN style mounting rails, including G profile rail

according to EN50035 - G32 , and top hat (T) profile rail according to EN50022 - 35 x 7.5 and - 35 x 15. The unit should be installed in a

location that does not exceed the maximum operating temperature and provides good air circulation. Placing the unit near devices that

generate excessive heat should be avoided.

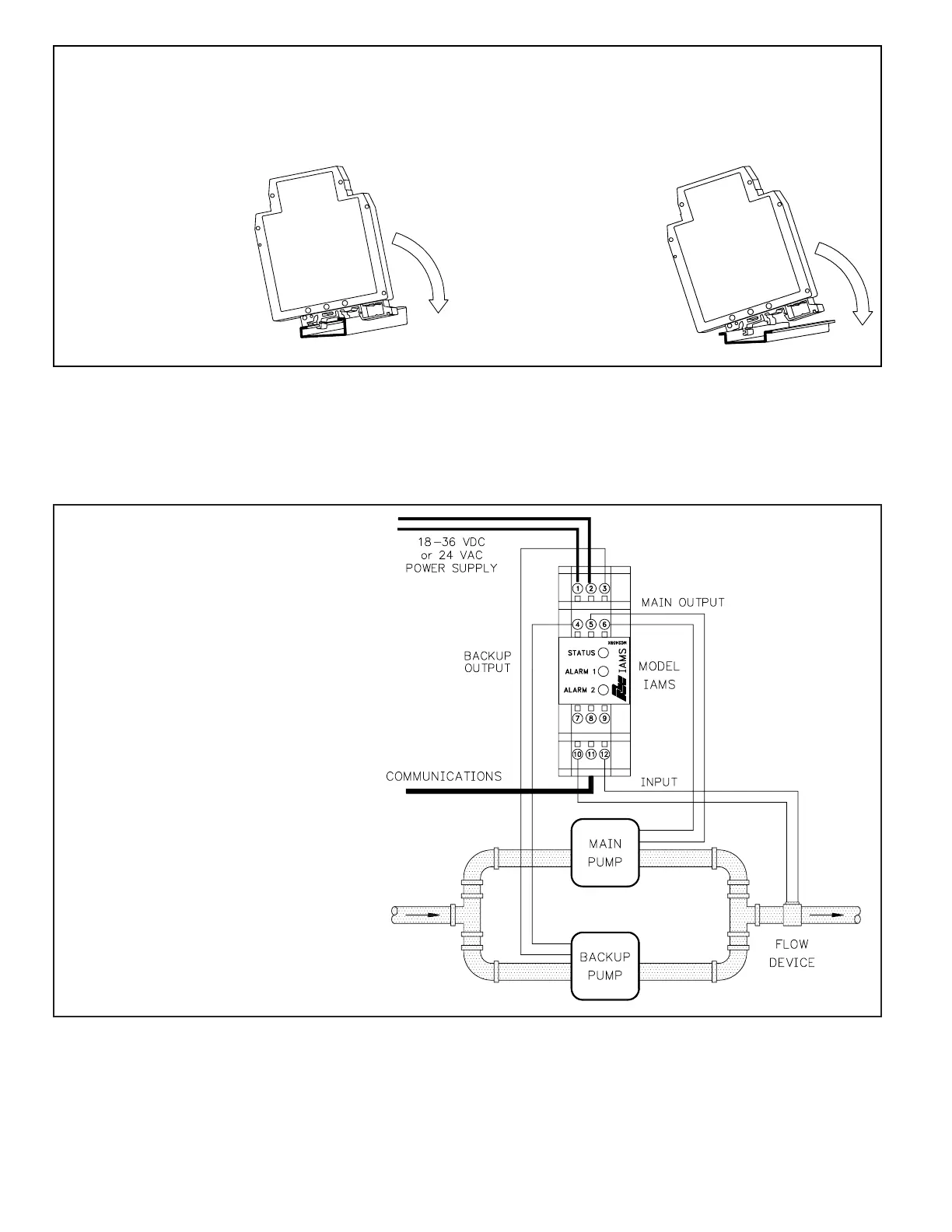

G Rail Installation

To install the IAMS on a “G”

style DIN rail, angle the module

so that the upper groove of the

“foot” catches under the lip of the

top rail. Push the module toward

the rail until it snaps into place.

To remove a module from the

rail, push up on the bottom of the

module while pulling out and

away from the rail.

T Rail Installation

To install the IAMS on a “T”

style rail, angle the module so

that the top groove of the “foot”

is located over the lip of the top

rail. Push the module toward the

rail until it snaps into place. To

remove a module from the rail,

insert a screwdriver into the slot

on the bottom of the “foot”, and

pry upwards on the module until

it releases from the rail.

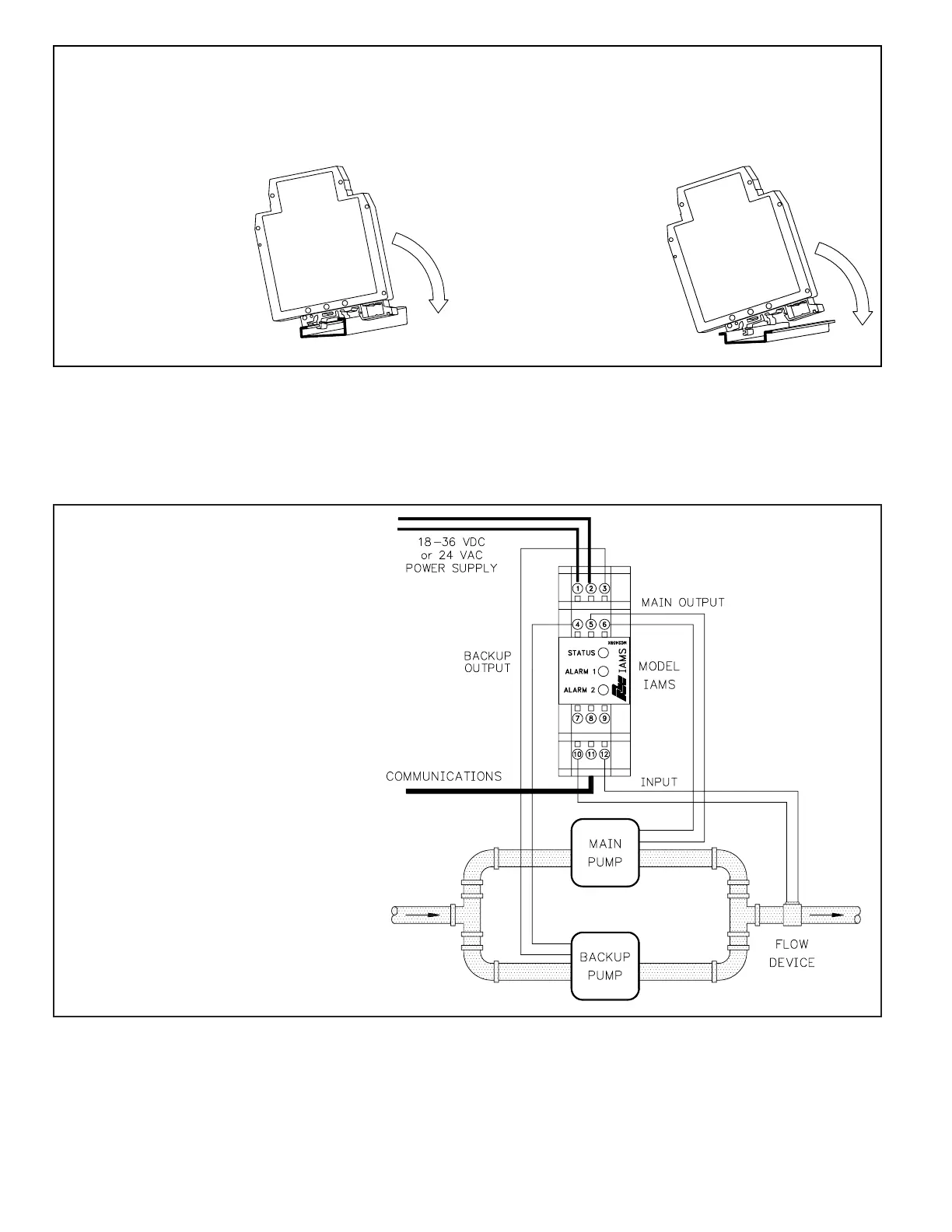

APPLICATION

Untreated waste needed to be pumped up a hill to a treatment

center. To prevent undesirable shut downs, a backup pump and

a flow transducer were installed in the line. The operator

needed the ability to monitor the flow, as well as the ability to

change setpoints from the main station, located 4000 feet away.

The temperature within the pumping station was not controlled.

The IAMS was installed because of the size, operating

temperature range, serial communications, and the ability to

control the pumps. When the flow is below a certain level, the

IAMS switches the Main Pump off, and the Backup Pump on.

Operators can monitor the flow and change the setpoints from

the main building using a PC acquisition program with a

MODBUS driver.

Loading...

Loading...