3

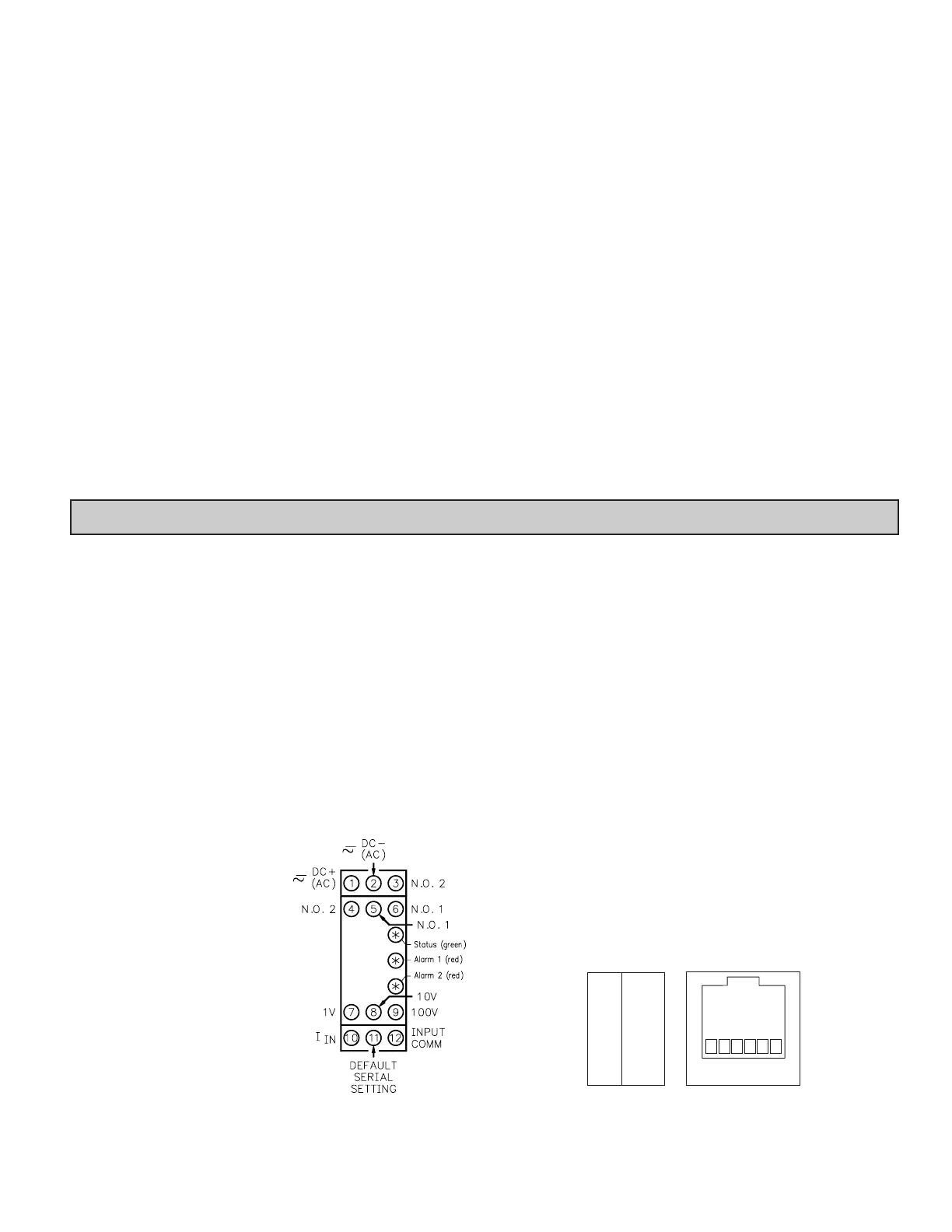

WIRING CONNECTIONS

All conductors should meet voltage and current ratings for each terminal.

Also, cabling should conform to appropriate standards of good installation,

local codes and regulations. When wiring the module, use the numbers on the

label to identify the position number with the proper function. Strip the wire,

leaving approximately 1/4" (6 mm) of bare wire exposed. Insert the wire into

the terminal, and tighten the screw until the wire is clamped tightly. (Pull wire

to verify tightness.) Each terminal can accept up to one #14 AWG (2.55 mm),

two #18 AWG (1.02 mm), or four #20 AWG (0.61 mm) wires.

MODULE POWER CONNECTIONS

Module power is connected to terminals 1 and 2. For best results, the power

should be relatively “clean” and within the specified limits. Drawing power

from heavily loaded circuits or from circuits that also power loads that cycle on

and off should be avoided. It is recommended that power supplied to the module

be protected by a fuse or circuit breaker.

INPUT CONNECTIONS

Current Input

Wiring for a current input is

connected to terminals 10 (+) and 12 (-).

Terminal 10 (+): 100 mA

Voltage Input

Wiring for a voltage input is

connected to terminal 12 (-) and one of

the voltage terminals listed below.

Terminal 7 (+): 1 VDC max.

Terminal 8 (+): 10 VDC max.

Terminal 9 (+): 100 VDC max.

RELAY OUTPUT CONNECTIONS

There are two Form A output relays. The wiring for Relay 1 is connected

between terminals 5 and 6. The wiring for Relay 2 is connected between

terminals 3 and 4.

To prolong contact life and suppress electrical noise interference due to the

switching of inductive loads, it is good installation practice to install a snubber

across the contactor. Follow the manufacturer’s instructions for installation.

Note: Snubber leakage current can cause some high impedance loads to be held

ON.

DEFAULT SERIAL SETTING CONNECTION

If the IAMS settings are unknown, or forgotten, they can be reset to the

factory defaults by connecting the Serial Default terminal 11 to Input Comm.

terminal 12 with a jumper, and then cycling power.

DEFAULTS:

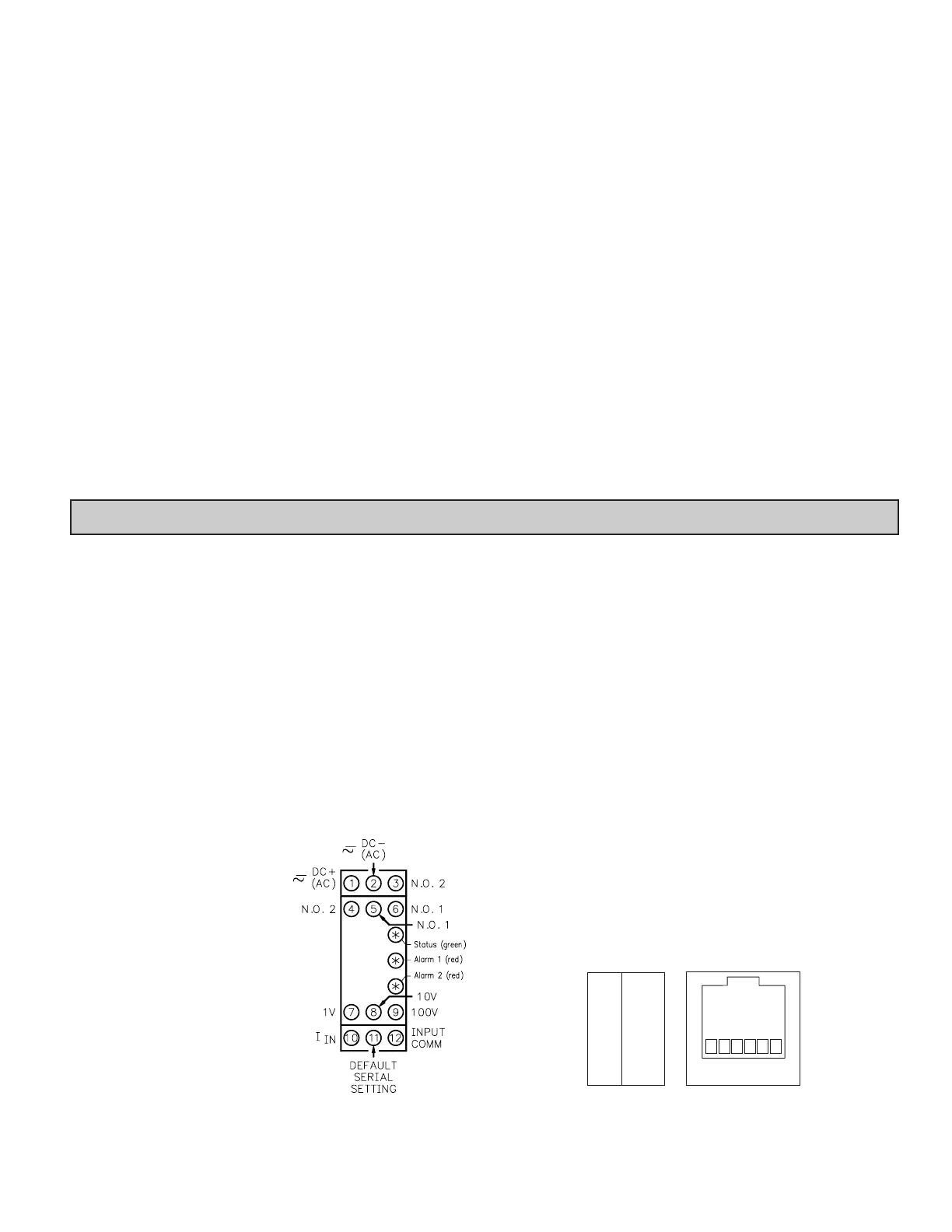

RS485 SERIAL CONNECTIONS

There are two RJ-11 connectors located on the bottom for paralleling

communications. For single device communications, either connector can be

used. When used in conjunction with Red Lion Control Paradigm HMI

products, reverse A+ and B- wiring.

STEP 1 WIRING THE MODULE

Protocol: RTU

Address: 247

Baud Rate: 9600

Data Bits:

Parity:

8

none

Although this unit is designed with a high degree of immunity to Electro-

Magnetic Interference (EMI), proper installation and wiring methods must be

followed to ensure compatibility in each application. The type of the electrical

noise, source or coupling method into the unit may be different for various

installations. Cable length, routing, and shield termination are very important

and can mean the difference between a successful or troublesome installation.

Listed below are some EMC guidelines for successful installation in an

industrial environment.

1. Use shielded (screened) cables for all Signal and Control inputs. The shield

(screen) pigtail connection should be made as short as possible. The

connection point for the shield depends somewhat upon the application.

Listed below are the recommended methods of connecting the shield, in order

of their effectiveness.

a. Connect the shield only at the rail where the unit is mounted to earth

ground (protective earth).

b. Connect the shield to earth ground at both ends of the cable, usually when

the noise source frequency is above 1 MHz.

c. Connect the shield to common of the unit and leave the other end of the

shield unconnected and insulated from earth ground.

2. Never run Signal or Control cables in the same conduit or raceway with AC

power lines, conductors feeding motors, solenoids, SCR controls, and

heaters, etc. The cables should be run in metal conduit that is properly

grounded. This is especially useful in applications where cable runs are long

and portable two-way radios are used in close proximity or if the installation

is near a commercial radio transmitter.

3. Signal or Control cables within an enclosure should be routed as far away as

possible from contactors, control relays, transformers, and other noisy

components.

4. In extremely high EMI environments, the use of external EMI suppression

devices, such as ferrite suppression cores, is effective. Install them on Signal

and Control cables as close to the unit as possible. Loop the cable through the

core several times or use multiple cores on each cable for additional

protection. Install line filters on the power input cable to the unit to suppress

power line interference. Install them near the power entry point of the

enclosure. The following EMI suppression devices (or equivalent) are

recommended:

Ferrite Suppression Cores for signal and control cables:

Fair-Rite # 0443167251 (RLC # FCOR0000)

TDK # ZCAT3035-1330A

Steward # 28B2029-0A0

Line Filters for input power cables:

Schaffner # FN610-1/07 (RLC # LFIL0000)

Schaffner # FN670-1.8/07

Corcom # 1 VR3

Note: Reference manufacturer’s instructions when installing a line filter.

5. Long cable runs are more susceptible to EMI pickup than short cable runs.

Therefore, keep cable runs as short as possible.

EMC INSTALLATION GUIDELINES

Loading...

Loading...