15

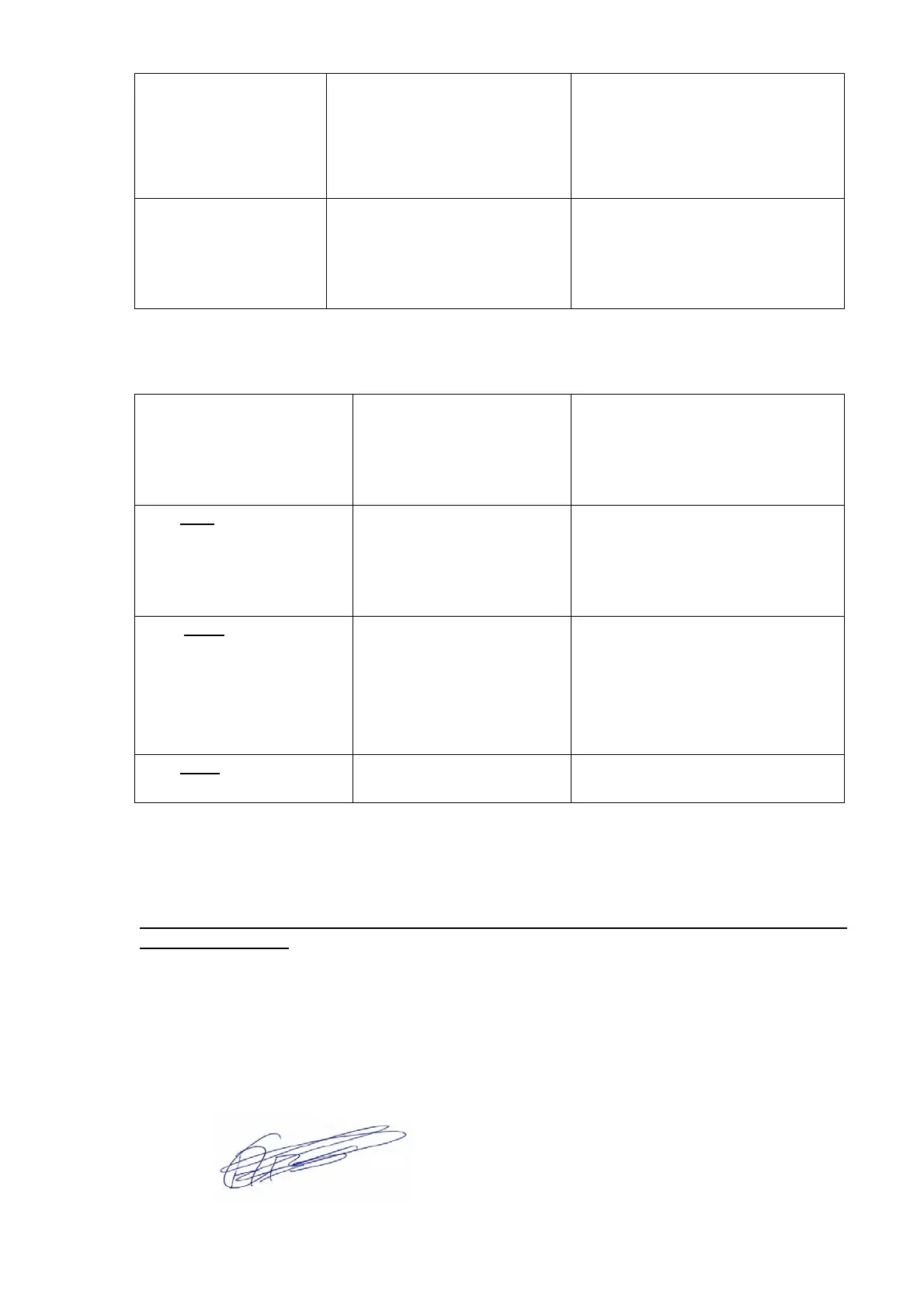

Crankshaft problems

Big end nuts slacken

Solve vibration, see vibration.

Crankshaft bearing collapsed.

Incorrect assembled after repair.

Remove, clean, use loctite

Rear roller shaking

Rear roller locked

Rear roller up with hollow coring

Tough circumstances

Unlock,

Change speed and PTO rev’s,

Put roller free on the ground,

Change machine settings.

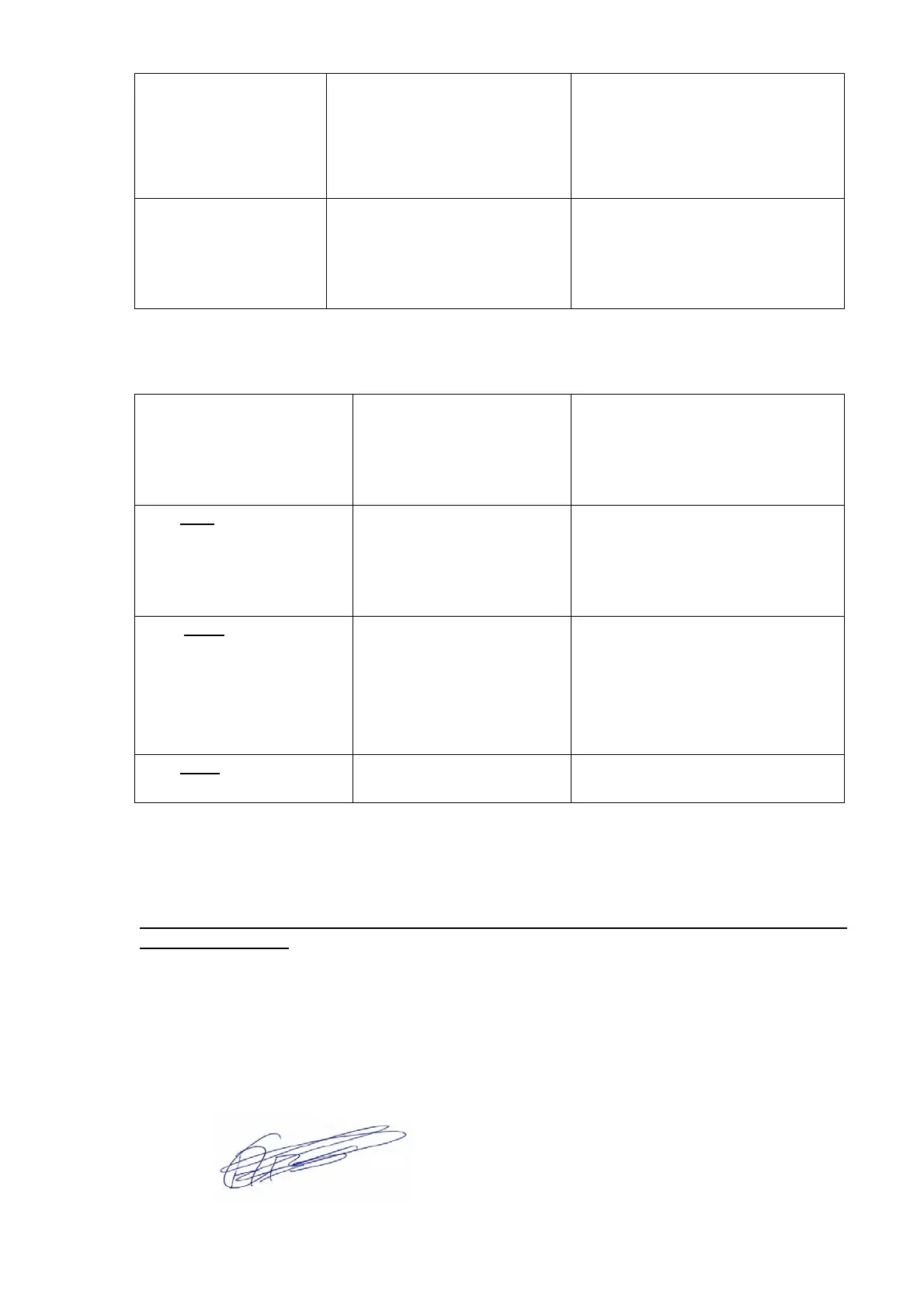

13.0 MAINTENANCE

Pre-Delivery-Inspection

Grease crankshaft bearings

Check bolts/ nuts

Connect the unit to a tractor

Run unit for 5 min

8 shots each EP 2

See instructions in this manual

Look and listen

After first 20 hours

(new or repaired)

Grease crankshaft bearings

Grease PTO and rollers

Check bolts/nuts

Look closely at machine

4 shots each EP 2

4 shots each EP 2

After every 100 hours

Grease crankshaft bearings

Grease PTO and rollers

Check bolts/ nuts

Look closely at machine

Grease spindles front roller

6 shots each EP 2

4 shots each EP 2

After every 500 operating

hours.

Replace the oil in the

gearbox.

Use 80W90 (5.8Ltr).

14.0 EU-DECLARATION

We, Redexim Utrechtseweg 127 3702 AC Zeist Holland, hereby declare fully on our authority that the

product:

VERTI-DRAIN 7521, WITH MACHINE NUMBER AS INDICATED ON THE MACHINE AND

IN THIS MANUAL,

to which this declaration relates is according to the stipulation of the 2006/42/EC directive for

machines as well as the following standards: NEN-EN-ISO 12100 : 2010 and NEN-EN-ISO 13857 :

2008.

Zeist, 01/10/09

A.C. Bos

Manager Operations & Logistics

Redexim Holland

Loading...

Loading...