IMPORTANT!! The mounting of the pressure relief valve supplied with

the water heater is Compulsory. It must be installed on the cold water

supply pipe.

Exception: If local regulations (norms) require the usage of another

protection valve or mechanism (in accordance with EN 1487 or EN 1489),

then it must be bought and fitted separately. For mechanisms operating in

accordance with EN 1487, the rated operational pressure must be no

more than 0.7 Mpa (7 Bar). For other protection valves, the pressure at

which they are calibrated must be 1 Bar lower than the one marked on the

appliance.

NB- In the circumstances above only, the safety valve which the appliance

is supplied with should not be used.

ATTENTION! Any other type of device should not be fitted between

the pressure relief valve and the appliance.

ATTENTION! Fixing the pressure relief valve to threads longer than

10 mm should not be attempted as this could damage

the valve.

ATTENTION! The pressure relief valve and the pipe between the valve

and the water heater must be protected from freezing.

During valve discharging - its free end must be always

open to the atmosphere (not immersed in water). we

recommend the use of a tundish.

The boiler is filled with water by opening the isolation valve on the cold water

supply system and the hot tap on the sink. After the filling process is complete, a

constant stream of water should flow from the hot tap. Now you can shut the hot

water tap on the sink.

If emptying the water heater, you must first isolate the power supply then close the

service valve and open the hot tap to de-pressurize the system before removing

the unit from the wall.

MAINTENANCE

Sacrificial Anode

In order to obtain the best performance from the heater, the sacrificial anode must

be checked every year.

Themagnesiumanodeprotectsthewatertank‘sinner surfacefromcorrosion.It

undergoeswearandtearandis shouldbereplacedperiodicallybytheuser.

Redringrecommendperiodicinspectionsofthe magnesiumanode’sconditionby

aqualifiedtechnician andreplacementwheneverrequiredtokeepyour

applianceworkingcorrectly.

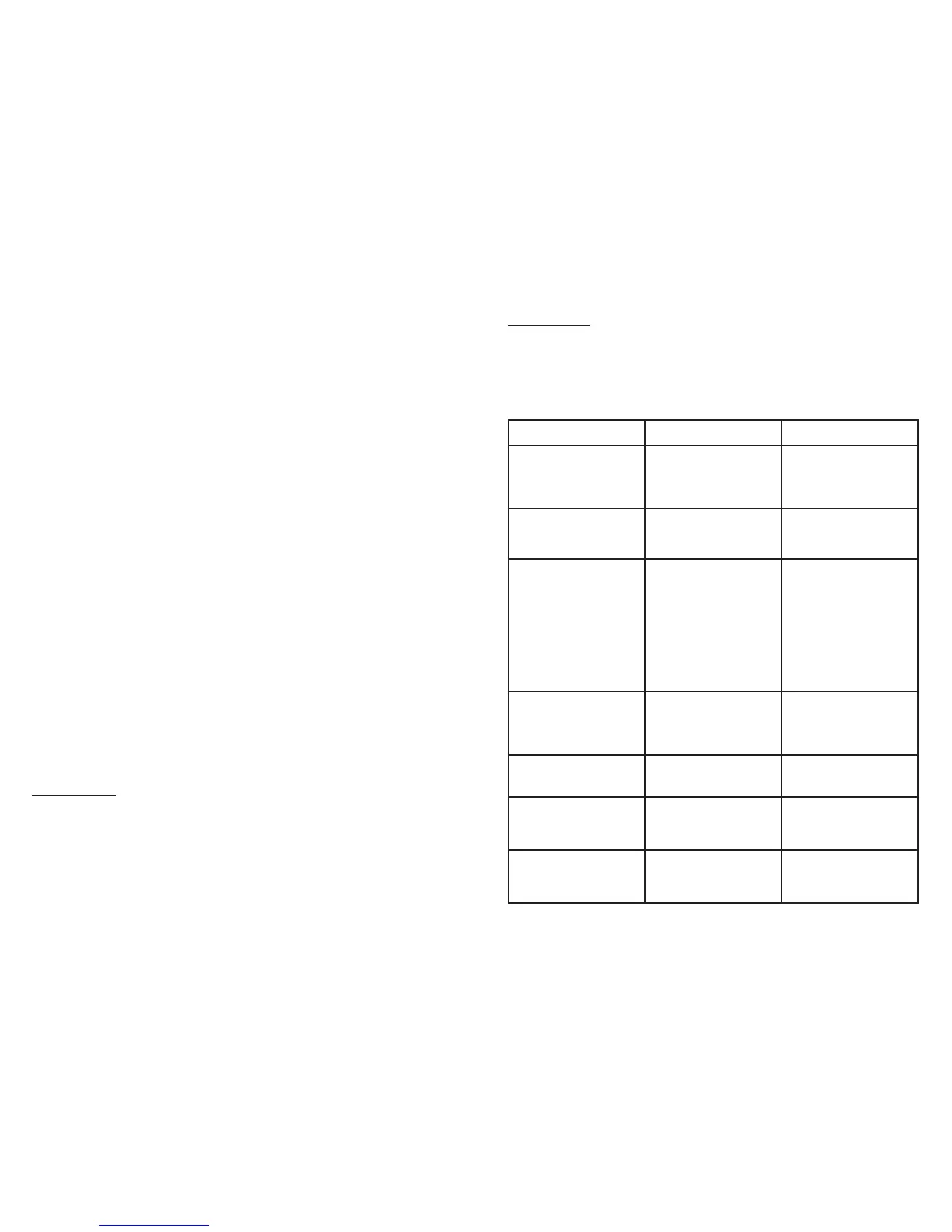

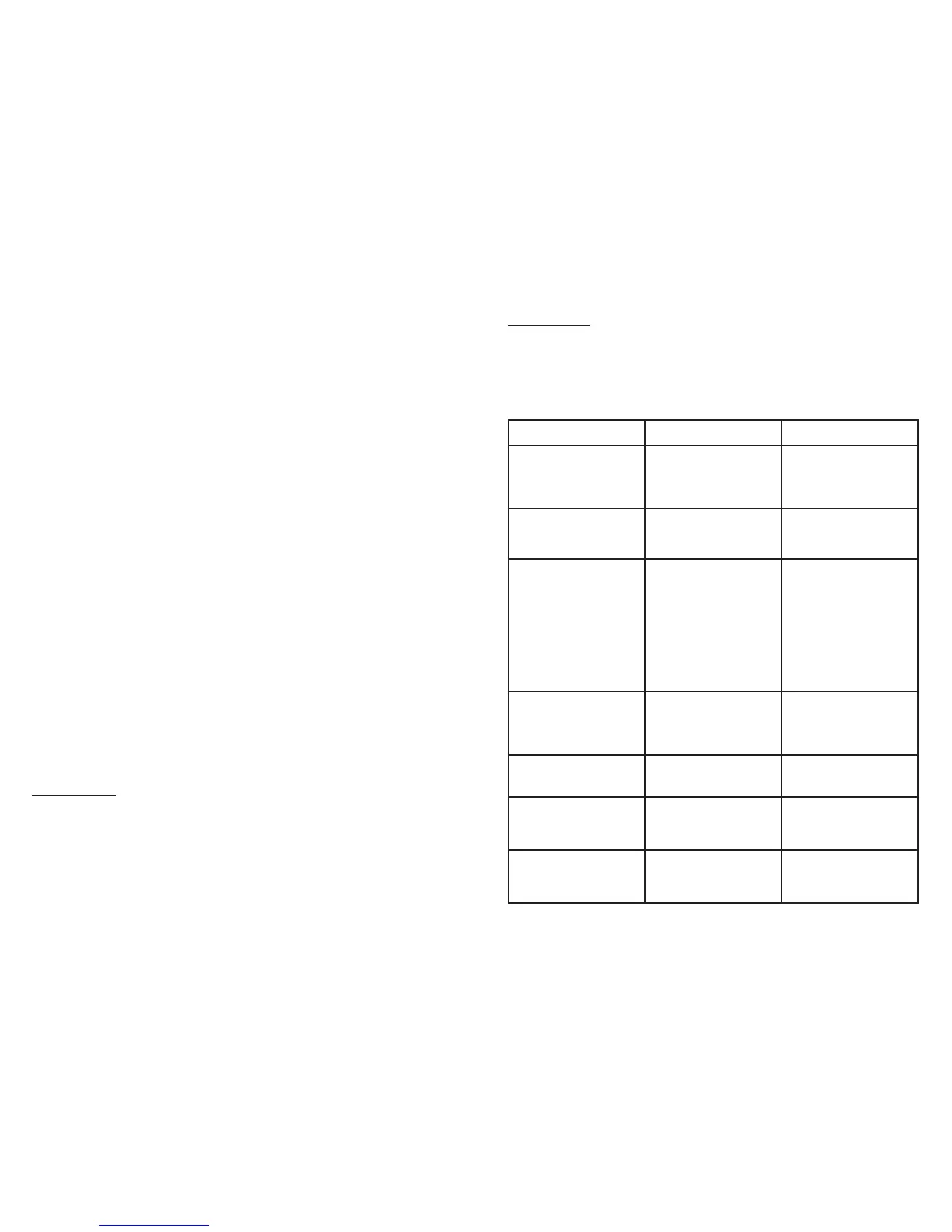

9

Not enough pipe work for

expansion (1.7m required)

Stop-cock, non-return valve

or pressure reducing valve

has been fitted within the

distance required for

expansion (see page 8,

diagram 5).

If an expansion vessel has

been fitted, the charge may

have failed

Loading...

Loading...