— English Servitec 35-95 with

— 18.12.2019 - Rev. A

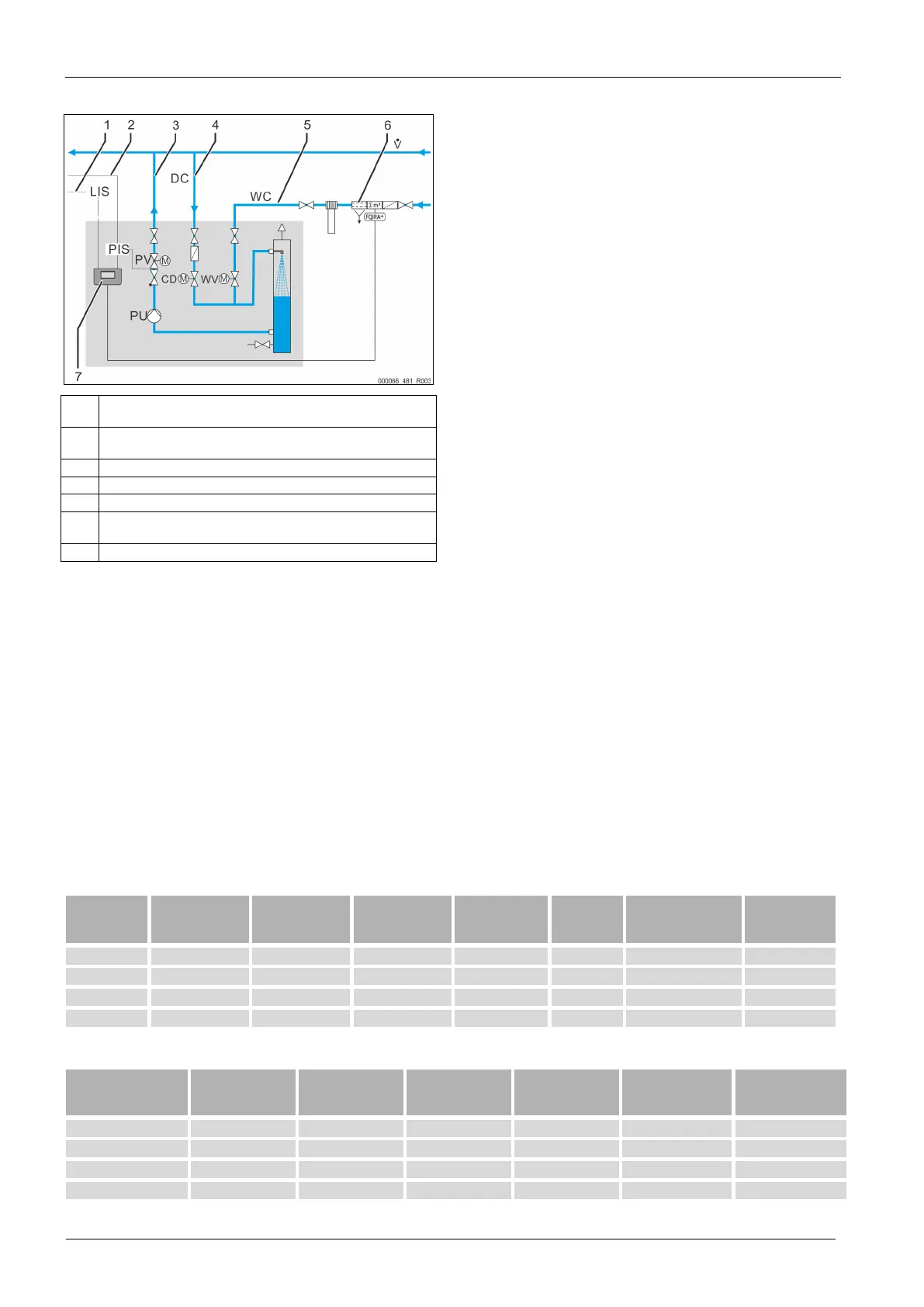

Servitec 35 - 95 with motorized ball valve

1 Control line of a pressure maintenance station for requesting the make-

up in "Levelcontrol" mode

2

Signal line from the "PIS" pressure transducer for the "Magcontrol"

make-up variant

3 "DC" degassing line (degassed water)

4 "DC" degassing line (gas-rich water)

5 "WC" make-up line

6 Optional equipment and accessories see chapter 4.6 "Optional

equipment and accessories" on page 6

7 Control Touch controller

4.5 Scope of delivery

The scope of delivery is described in the shipping document and the content is

shown on the packing.

Immediately after receipt of the goods, please check the shipment for

completeness and damage. Please notify us immediately of any transport

damage.

Basic degassing equipment:

• Control of the Servitec.

• "DV" degassing valve, box-packaged.

• Plastic sleeve with operating manual and electric wiring diagram (attached

to the Servitec).

The Servitec is pre-assembled and shipped on a pallet.

4.6 Optional equipment and accessories

The following optional equipment and accessories are available for this device:

• Fillsoft/Fillsoft zero for softening/desalination of the make-up water from

the potable water supply system. Replacement of the softening and

desalination cartridges.

• Fillset for make-up with water

– Fillset with integrated backflow preventer, water meter, dirt trap,

and shut-ff for the "WC" make-up line

• Fillset Impulse with FQIR+ contact water meter for make-up with water.

– If the Fillset Impulse is installed, you can regulate the entire make-up

quantity and the soft water capacity of Fillsoft softening systems. The

operational reliability of the device is assured and prevents

automatic make-up during major water loss or small leaks.

• Fillset Compact for make-up

– Fillset Compact with integrated system separator, dirt trap, and shut-

off for the "WC" make-up line.

• Fillguard for conductivity monitoring

– If the Fillguard is fitted, the capacity of the Fillsoft Zero desalination

cartridge can be monitored based on the conductivity.

• Enhancements for the device controller.

– Various controller information can be queried via the RS-485 interface

and it can also be used to communicate with control centres or other

devices, see chapter 6.5.3 "RS-485 interface" on page 12 .

• Bus modules for the communication with control centres.

• Profibus-DP.

• Ethernet.

– I/O module for standard communication.

• Modbus RTU

• Control Remote

• Gas discharge measurement for optimised degassing operation.

Note!

Separate operating manuals are supplied with accessories.

5 Technical data

Note!

The following values apply for all systems:

– Permissible operating temperature of the device:

–

Permissible inlet pressure for make-up:

Make-up capacity:

Separation level, dissolved gases:

Separation level, free gases:

1.3 bar – 6 bar

Up to 0.55 m³/h

≤ 90 %

100 %

5.1 Electrical system

Number of RS-485

interfaces

35 0.85 230 / 50 10 2 Optional 230, 2 55

60 1.1 230 / 50 10 2 Optional 230, 2 55

75 1.1 230 / 50 10 2 Optional 230, 2 55

95 1.1 230 / 50 10 2 Optional 230, 2 55

5.2 Dimensions and connections

Servitec input

connections (system

and make-up)

Servitec output

connection

35 30 965 553 486 Internal thread ½ " Internal thread 1 "

60 36 1150 600 486 Internal thread ½ " Internal thread 1 "

75 41 1150 573 635 Internal thread ½ " Internal thread 1 "

95 42 1150 573 635 Internal thread ½ " Internal thread 1 "

Loading...

Loading...