STR 0PA 15

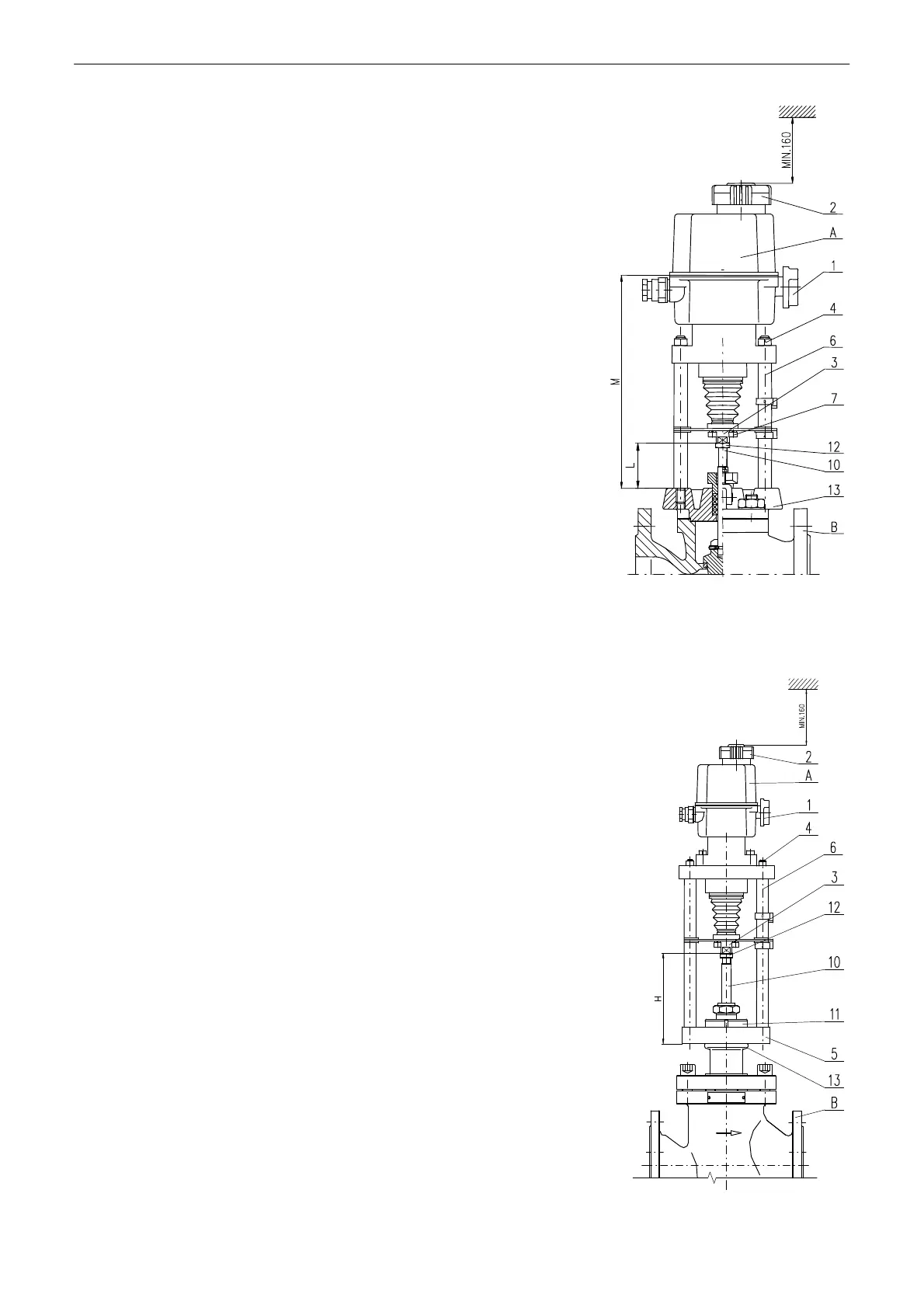

Mechanical connection for pillar version - Fig. 3

Connection procedure:

• Check the labels, whether the travel of electric actuator and

travel of armature are corresponding.

• The valve (B) is put to the position „closed“ and the actuator (A) to

a half-position.

• Loosen the nuts (4) on the pillars (6).

• Screw the pillars (6) with the cross system into the valve flange

(13).

• Tighten the pillars (6) nuts.

• Unscrew the coupling (3) screws (7) to dismantle the coupling into

parts.

• Screw the coupling (3) nut onto the valve shaft (10) to reach the

connecting size L in accordance with the table and the actuator

nameplate.

• Unscrew the coupling (3) nut by one revolution and lock it by a nut

(12).

• Use the hand wheel (2) to put the actuator output shaft next to the

valve (10), and screw the coupling parts together.

A ........... electric actuator B ................ valve

1 ........... disengagement button 10 ............... valve shaft

2 ........... hand wheel 12 ............... locking nut

3 ........... coupling nut 13 ............... valve flange

4 ........... pillar nut

6 ........... pillar

7 ........... coupling screw

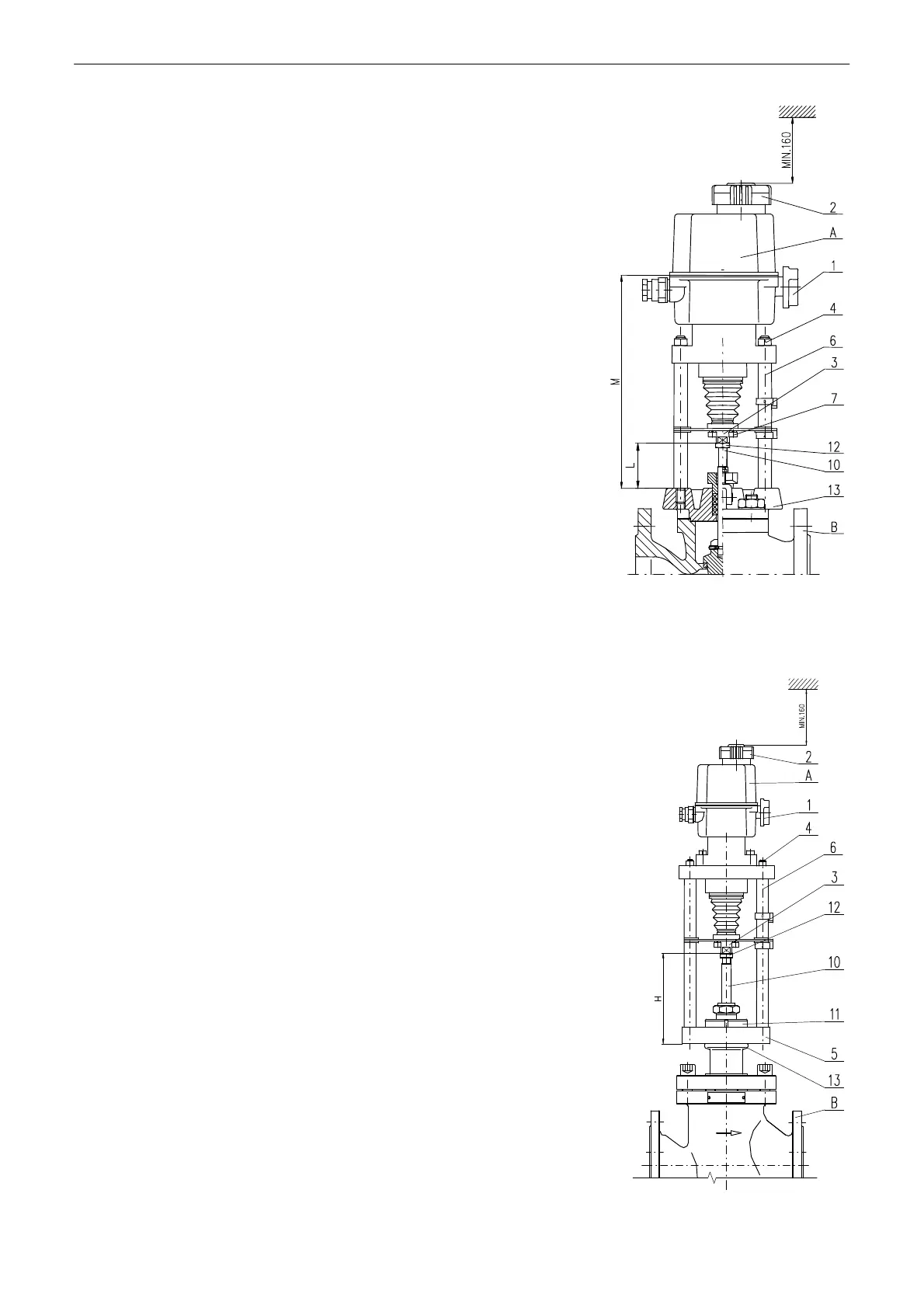

Mechanic connection with the flange - (Fig. 4)

Connecting procedure:

• Check the labels, whether the travel of electric actuator and travel

of armature are corresponding.

• Set the armature (B) into position „closed“ and set electric actuator

(A) into half-position.

• Put electric actuator (A) on the armature (B).

• Unscrew the clutch bolts (3) and disassembly parts of the clutch.

• Screw the nut of clutch (3) on output shaft of armature (10) in a way,

that the flange of electric actuator (5) will fit to the flange of armature

(13).

• Connect the flanges by tightening of central nut (11).

• Check connecting dimension "H" between the clutch and the flange

(13) in the position of contact with pillars according to dimensional

drawing and a type number on the plate of electric actuator.

• Release the clutch nut (3) by one turn counter clockwise and secure it

by nut (12), thereby reaching pre-stress securing proper seating of

armature.

• By hand wheel (2) approach output shaft of electric actuator to the

shaft of armature (10) and fasten parts of the clutch by bolts.

A ...........electric actuator

1 ...........disengagement button

2 ...........hand wheel

3 ...........coupling nut

4 ...........pillar nut

5 ...........actuator flange

6............pillar

B ........... valve

10.......... valve

shaft

11... connecting nut

12 ............locking

nut

13 ............valve

flange

Fig. 3

Fig.4

Loading...

Loading...