24 STR 0PA

3.8 Error messages from the control unit

The EA electronics makes possible to identify some failures of EA. The failure is signalled by flickering

LED ERROR (red) on the control unit (Fig.6). An error has also been indicated on the LED display. An

error is indicated on the LCD display in the local control EA version.

The list of errors and warnings compiled by the producer is presented in table 3 (chapter 4.3).

The list of errors and warnings and the way for identifying a given error as well are presented in the

separate attachment No 74 1053 02.

A field serviceman is only entitled to change the errors and warnings set using the programme

once the EA is connected to the PC.

4. Service and Maintenance

4.1 Service

1. In general it is provided that service of the EA is performed by a qualified worker in accordance with

requirement given in Chapter 1!

2. After putting the EA into operation it is needed to verify whether during manipulation any scratch on

surface occurred, it is to be removed to prevent actuator against corrosion!

The EA STR 0PA requires just negligible service. Proper putting into operation is a recondition of

reliable operation.

The service of the EA leads from the operation conditions and usually resides in information

processing for further arranging of required functions.

The stuff has to perform prescribed maintenance to prevent the EA during operation against

impacts of environment, which exceed the frame of allowed influences.

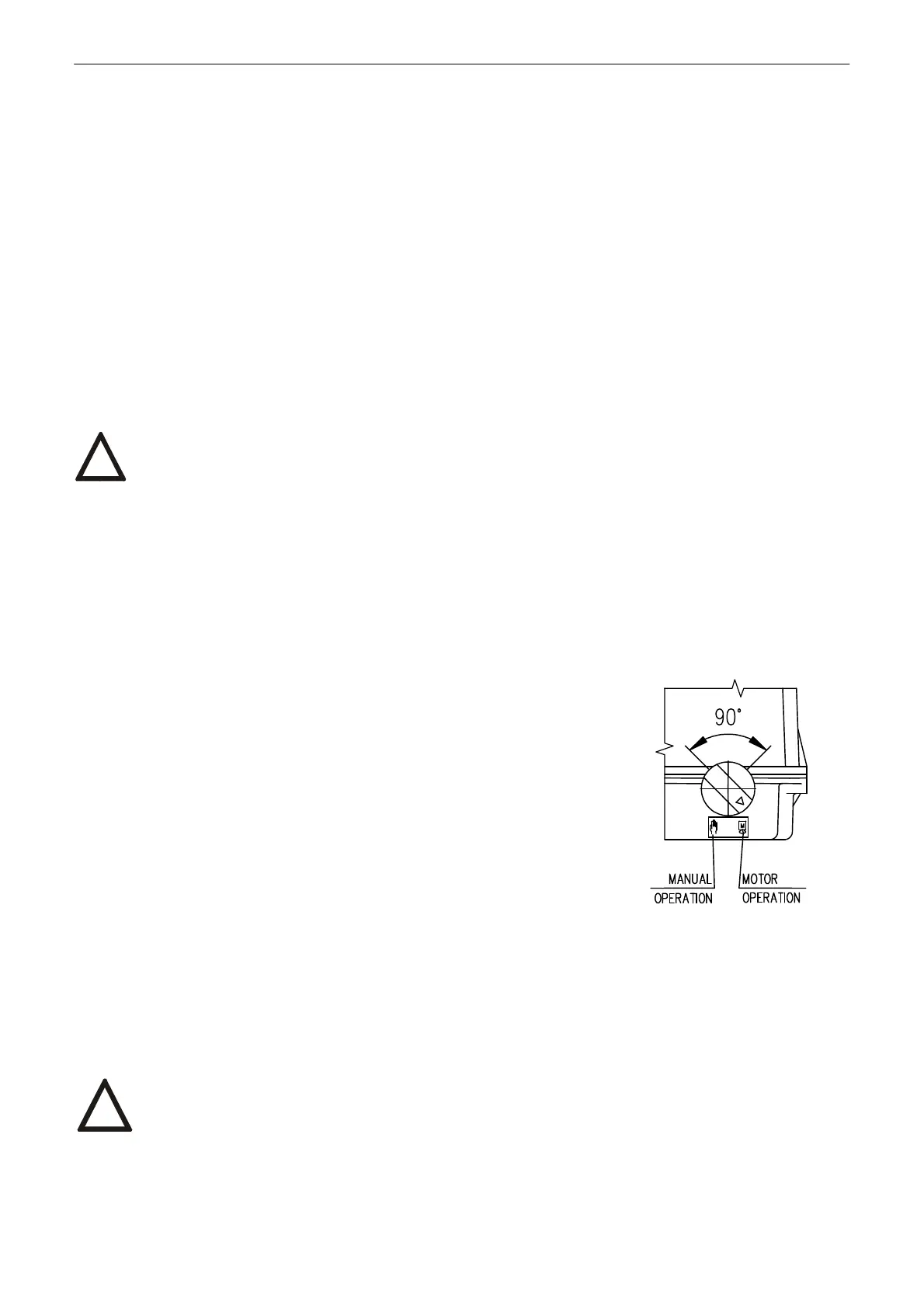

Manual control:

If needed (during adjusting, function checking, failure etc.) the stuff can change setting of the

controlled body using the handle.

Instructions for manual control:

• Switch the power supply off.

• Turn the button for gear disengagement to the right by 90° (Fig. 10),

the button arrow shows the symbol of hand) what disengages the

gear in the actuator.

• Push and turn the hand wheel located on the actuator upper cover.

While turning counter clockwisely the valve is turning in the direction

"open". Having the valve in the required position turn the button for

gear disengagement to the position "motored operation" what

engages the gears

1)

. Put the hand wheel back to its original position.

1)

In case, when after return of pushbutton for gear disconnection to

position motoric operation will the gear not be meshed, it is necessary to

turn by the wheel of manual control in order to mesh the toohed wheels.

One of the possible errors may be that the button disconnecting the gear after the manual control was

not released to motor control position. In this case the EA will stop after certain time of motor

operation.

Manual control of the actuator does not result in derangement of the set limit positions

provided that the connection dimensions are complied with according to a specific dimension

sketch as well as the corresponding stroke

!

Fig. 9

Fig.10

!

Loading...

Loading...