TT-S4/D

1877G APR 19

Box 116

428 22 KÅLLERED SWEDEN

Tel +46 (0)31 720 02 00 Fax +46 (0)31 720 02 50

3

INSTRUCTION INSTRUCTION

Step controller for electric heating

TT-S4/D is a microprocessor-based step controller designed for use

together with Regin’s TTC controllers. It has a control input signal

of 0 - 10V DC. It has four relay outputs for controlling four heater

groups. The TT-S4/D can be set to control either a heater with equal

loads giving 4 steps, or a heater where the load is binary divided

giving 15 steps. The TT-S4/D also has a 0 - 10V DC output for

controlling a triac controller for smoothing the power output between

the relay steps. The maximum number of relay steps can be limited

using a switch on the front.

TT-S4/D has a built in test program for simple function testing.

TT-S4/D is built for DIN-rail mounting with all settings accessible on

the front.

Installation

Mount the TT-S4/D on a DIN-rail in a cabinet or other enclosure.

Protection class: IP20.

Ambient temperature: 0 - 50°C.

Wiring

Supply voltage

Supply voltage: 24V AC +/-15% 50-60Hz.

Power consumption: 6 VA.

Terminal 11 = Phase.

Terminal 12 = Neutral.

Control input

Control voltage 0 - 10V DC from a TTC25, TTC40F or TTC80F con-

troller, or other controller with a 0 - 10V input.

Terminal 13 = 0 - 10V DC input.

Terminal 15 = Signal neutral.

Control output

The control output is used to control a triac controller that will give

0 - 100% power between each relay step. The load connected to the

triac controller should have the same size as the load connected to

relay 1.

TT-S4/D automatically adjusts the ratio between the input signal

and the output signal according to the setting of the maximum step

switch.

Terminal 19 = 0 - 10V DC output.

Terminal 21 = Signal neutral.

Relay outputs

Relays 1 - 4, SPST with a common supply pole. 240V AC 2A

total.

When the heater is binary divided the loads must be wired in

rising size with the smallest load on relay 1.

Terminal 6 = Common relay input 2A 250V AC.

Terminal 1 = Relay 1 output.

Terminal 2 = Relay 2 output.

Terminal 3 = Relay 3 output.

Terminal 4 = Relay 4 output.

N.B. The supply to terminal 6 must be wired so that the power

is cut in the event of the fan motor relay or the heater high-limit

switch tripping.

Signal converter

TT-S4/D contains a signal converter that converts a 10 - 2V DC

input signal to a 0 - 10V DC output signal.

This is used when TT-S4/D is controlled by for example TA-con-

trollers with a 10 - 2V DC output.

Terminal 14 = 10 - 2V DC input

Terminal 20 = 0 - 10V DC output, connect to terminal 13.

Settings

Binary - Sequential switch

Set to S if all the load is divided into equal parts.

Set to B if the load is binary divided, i.e. if the parts have the

size-ratio of 1:2:4:8.

Maximum number of permitted relay steps

With the rotary switch you set the maximum number of relay

steps to be used.

To ensure correct control it is important that the switch is correct-

ly set. During sequential control (S), all positions > 4 correspond

to a maximum of 4 relay steps being connected. Position 0 is the

starting position for the built-in test function.

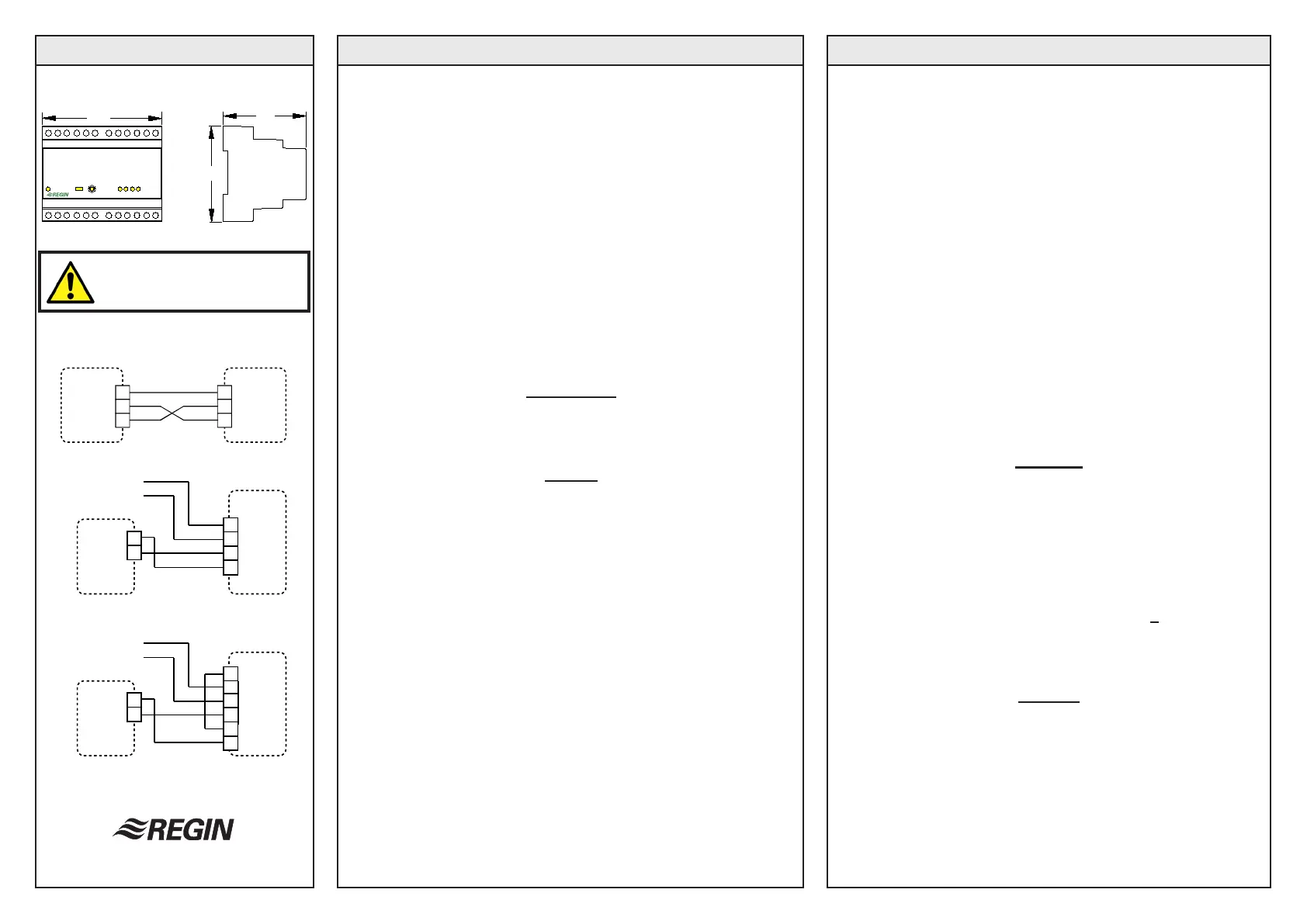

Figures

Fig 1: Wiring of TTC25/TTC40F/TTC80F when the system is

controlled by a sensor connected to TTC25/TTC40F/

TTC80F

Fig 2: Wiring of TTC25/TTC40F/TTC80F and 0...10V DC

control signal from an external source.

Fig 3: Wiring of TTC25/TTC40F/TTC80F and 10...2V DC

control signal from an external source.

IMPORTANT: Read these in-

structions before installation and

wiring of the product.

101

74

85

TT-S4/D

TTC25

TTC40F

TTC80F

TT-S4/D

8

9

+

0

0...10 V DC in

13

15

19

21

TT-S4/D

8

9

+

0

10...2 V DC in

13

15

19

21

14

20

TTC25

TTC40F

TTC80F

TTC25

TTC40F

TTC80F

TT-S4/D

7

8

9

13

19

21

Fig 1

Fig 2

Fig 3

Loading...

Loading...