8.7 Faults

Note!

In case of faults, determine the cause before disassembling to eliminate the error with as little

maintenanceworkaspossible.

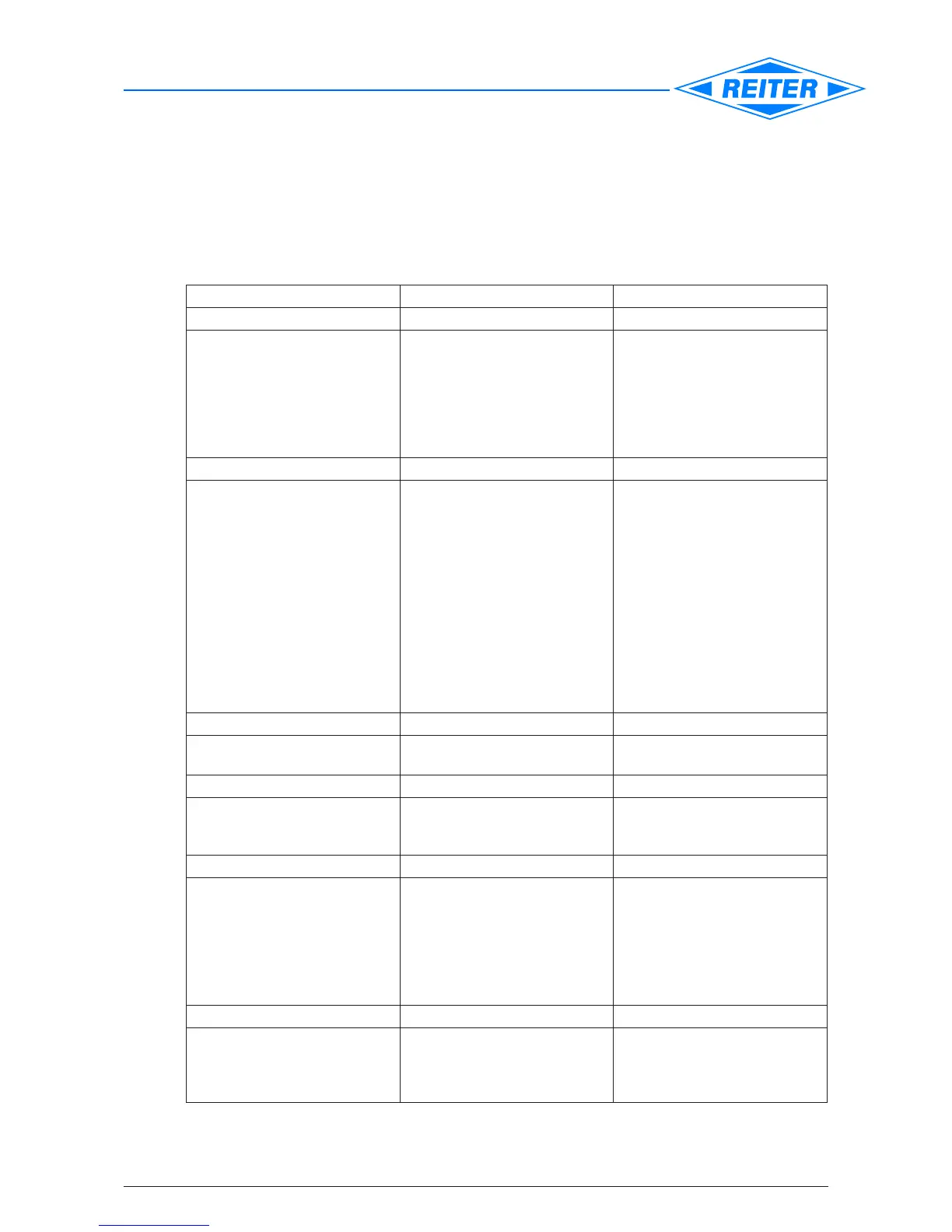

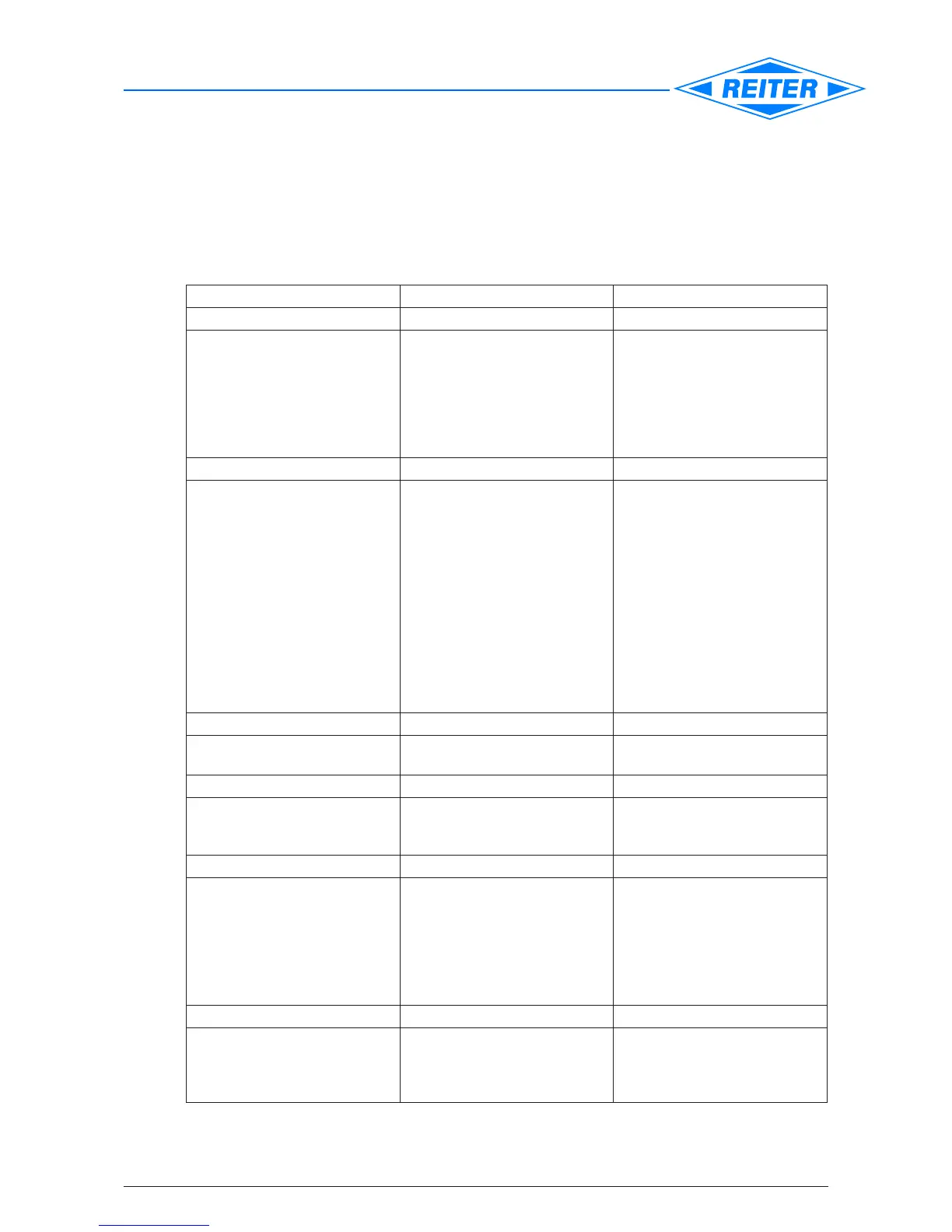

Faults Possible causes Corrective action

Nouniformatomizationor

spray pattern is not symmetri-

cal

Nozzlestuckordamagedor

deformed on the paint trailing

edge

Air cap holes are clogged in

complete or in part, or de-

formed

Cleannozzle/aircapwith

suitable cleaning material or

replace it

Insufcientatomization/fanair Fanairandatomizerairare

not set correctly

Air cap and/or air distribution

ring have not enough through-

put

Cable cross-section capacity is

too low or narrows by screw-

ing,kinkingpointsorsimilar

Nozzlecross-sectioncong-

ured incorrectly

Readjustfanairandatomizer

air

Replace air cap or/and air

distributing ring

Revise cable cross-section,

replacescrews,cutoutkinking

points and/or use new hose

Replacenozzle

Atomization/fanaircannotbe

shut off completely

Defective proportional valve or

pressure regulating valve

Replace defective component

Atomization/fanaircannot

properly regulate

Seals at air distributing ring

not installed properly or not

present

Replace seals

Materialowtoolowornon-

existent

Cloggednozzle

Mainneedlestiff/blocked

Piston or needle set glued

Cleannozzle

Control pressure should not

fall below 5.0 bar

Clean piston or replace needle

set

Paint outlet at the gun Needle set or needle worn

(paintoutletonhousing)

Maintaingun

Replace needle set and/or

needle

Loading...

Loading...