Operating the machine

24

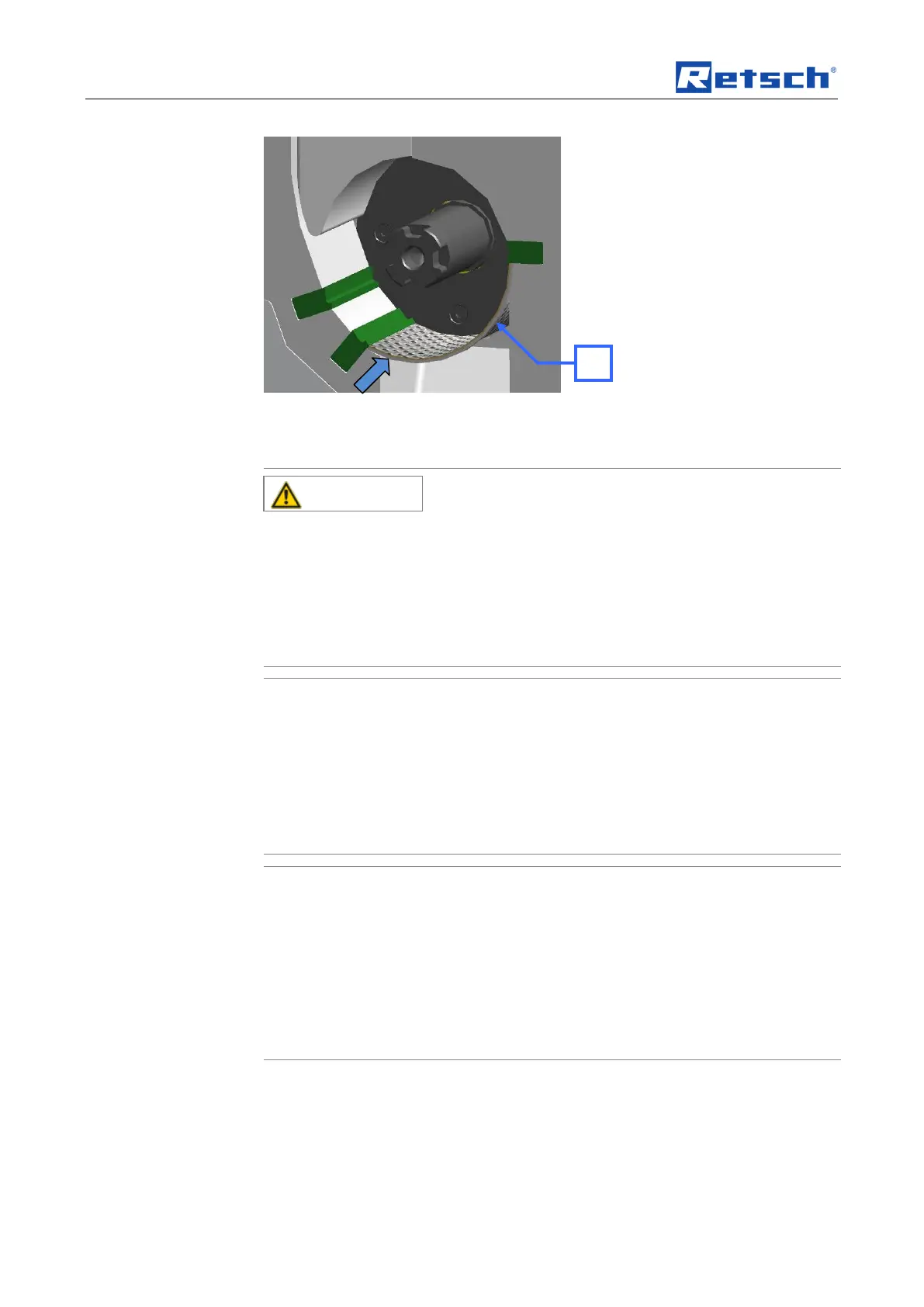

Fig. 12: Inserting the bottom sieve

5.6 Replacing the rotor

Injuries in the form of cuts

Sharp cutting edges on the rotors and cutting bars

– The sharp cutting edges on the rotors and cutting bars can injure hands.

• Wear protective gloves when replacing the cutting rotors and

cleaning the grinding chamber.

• Use the rotor extraction tool when handling the cutting rotors.

Reduction of tool service life

Abrasive sample materials

– The presence of abrasive composite materials during grinding can

considerably reduce tool service life.

• When grinding electronic scrap, take the properties of the composite

materials into account.

Damage to mechanical components

Blockages typical of cutting mills

– When coarse, solid material is fed in for grinding, the high feeding capacity

of the standard rotor can cause blockages that are typical of the cutting

mills.

• If blockages occur, switch off the mill immediately and remove the

clogging material.

NB

2.H0055

It is necessary to check whether the cutting gap is larger than 0.3 mm before each

grinding operation using the parallel section rotor.

• Open the grinding area door.

Loading...

Loading...