REYMSA COOLING TOWERS, INC.

www.reymsa.com

The

All-Fiberglass

Cooling Towers

63

Operation

C.3.2 SCALE FORMATION

Scale is the most widely-known water-caused trouble. Indeed the term is so familiar that it is often

applied incorrectly to all solid accumulations in water systems. Scale is but a single type of fouling; others

being sedimentation, corrosion, slime, etc. A true scale forms by crystallization of a dissolved salt when its

concentration exceeds its solubility.

The most common formed scale consists of:

▪ Calcium Carbonate (lime scale)

▪ Calcium Sulfate and silica

▪ Algae growth, slime, and other micro-organisms

C.3.3 BIOLOGICAL GROWTH

Slime and algae in cooling systems are frequently spoken of and handled as though they were a single

word and single problem. Algae require sunlight for their growth, which can be prevented by reducing

the sunlight exposure. Minimizing the development of algae and bacterial slimes is important because

they reduce the heat transfer, decrease cooling water flow, localize corrosion, and serve as a mortar for

permitting rapid build-up of deposits consisting of an agglomeration of sediments, corrosion products, and

scale.

The aim in cooling water treatment is microbiological control to avoid significant slime or algae growth, not

the almost impossible goal of maintaining circulating water completely sterile. The many treatment chemicals

available for microbiological control in Cooling Towers include chlorine and other compounds which yield

available chlorine, some of these compounds have broad spectrum effectiveness and others are specific for

a more limited range of organisms

Periodic measurement of the overall bacterial population of the water is recommended to maintain a

biological control.

Finally, whenever flagrant microbiological growths develop, chemical or mechanical cleaning must be included

along with micro biocide treatment in any effective program for promptly re-establishing microbiological

control.

Cooling Tower must be cleaned periodically to prevent the growth of bacteria

including legionella pneumophica, to avoid the risk of sickness or death.

CAUTION

C.3.1 SUSPENDED SOLIDS

Sedimentation of solid materials occurs in the Tower basin, pipes and equipment as a product of corrosion,

mill scale particles, silt or fly ash scrubbed from air by the Cooling Tower. It is recommended that every

Cooling Tower is fitted with a solid separator. REYMSA offers a centrifugal separator as a design option for

suspended solids control (see Figure C-8).

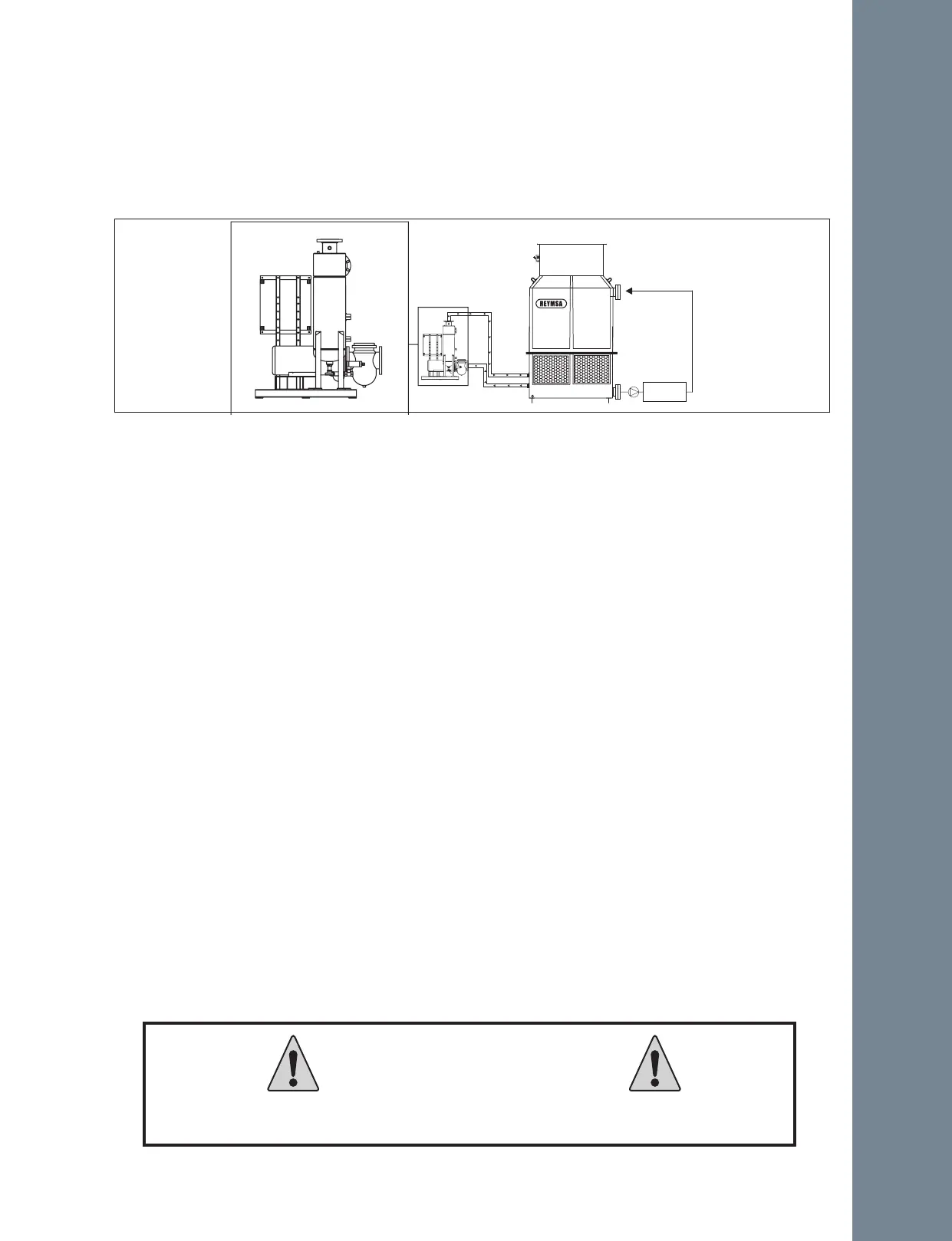

Figure C-7: Filtration system

Pump

Pump

Centrifugal

Separator

Filter

Control Panel

From the System

To the

System

Process

Loading...

Loading...