Form I-X, P/N 150491 R7, Page 19

8.4.2 Optional Two-

Stage Operation for

Heating Only

The standard combination control valve is replaced with a two-stage combination gas

control valve providing for low re or high re operation controlled by a two-stage

thermostat. First stage (low re) is factory set (not eld adjustable). Both high and low

stages are controlled by a Servo regulator, maintaining constant gas input under wide

variations in gas supply pressure. See instructions packed with the unit for specic gas

valve specications, wiring, and operating instructions.

8.4.3 Optional Two-

Stage Operation for

Makeup Air

Two-stage makeup air units are equipped with a two-stage gas valve, but instead of

control from a two-stage room thermostat, the outlet air temperature is monitored and

controlled by a two-stage ductstat. When the discharge air temperature drops to the

setpoint, low re is energized. If low re cannot satisfy the ductstat setting, high re is

energized.

Makeup air applications are usually adjusted to discharge an outlet air temperature

between 65°F and 75°F. In all applications, the allowable temperature rise of the fur-

nace in the installation dictates the limits of the ductstat temperature setting.

Depending on the option selection, the factory-installed sensor is either eld-connected

by capillary tubing to the unit-mounted ductstat (FIGURE 18) or electrically connected

to a remote electronic temperature selector (FIGURE 20). The remote temperature

selector is available with or without a display module.

See FIGURE 19 for a general location of the factory-installed sensor with either the

factory-mounted or the remote ductstat selector option.

Optional Ductstat with Capillary Tubing (Option AG3) - The ductstat illustrated in

FIGURE 18 is used with Option AG3. The control is set to 70°F and has an adjustable

range with a xed differential of 2-1/2°F. Due to different CFM settings and outside air

temperature, the average downstream outlet temperature may not match the ductstat

setting exactly. After the installation is complete, adjust the setpoint of the ductstat to

achieve the desired average outlet air temperature.

Adjustable range

0-100°F with a xed

differential of 3°F.

FIGURE 18- Ductstat

Control in Option AG3

FIGURE 19 - Duct Temperature

Sensor Location

Sheetmetal

Retaining Plate

Gasket

Sensor Capillary

Sensor Bracket

(NOTE:

.)

1. Remove access panel in

ductwork adjacent to control com-

partment access panel.

2. Element is retained by spring

clips.

3. Round gasket and metal retaining

plate provide air tight seal for

capillary and must be removed to

remove the element.

WARNING: The operating valve is the prime safety shutoff. All gas supply lines must

be free of dirt or scale before connecting the unit to ensure positive closure.

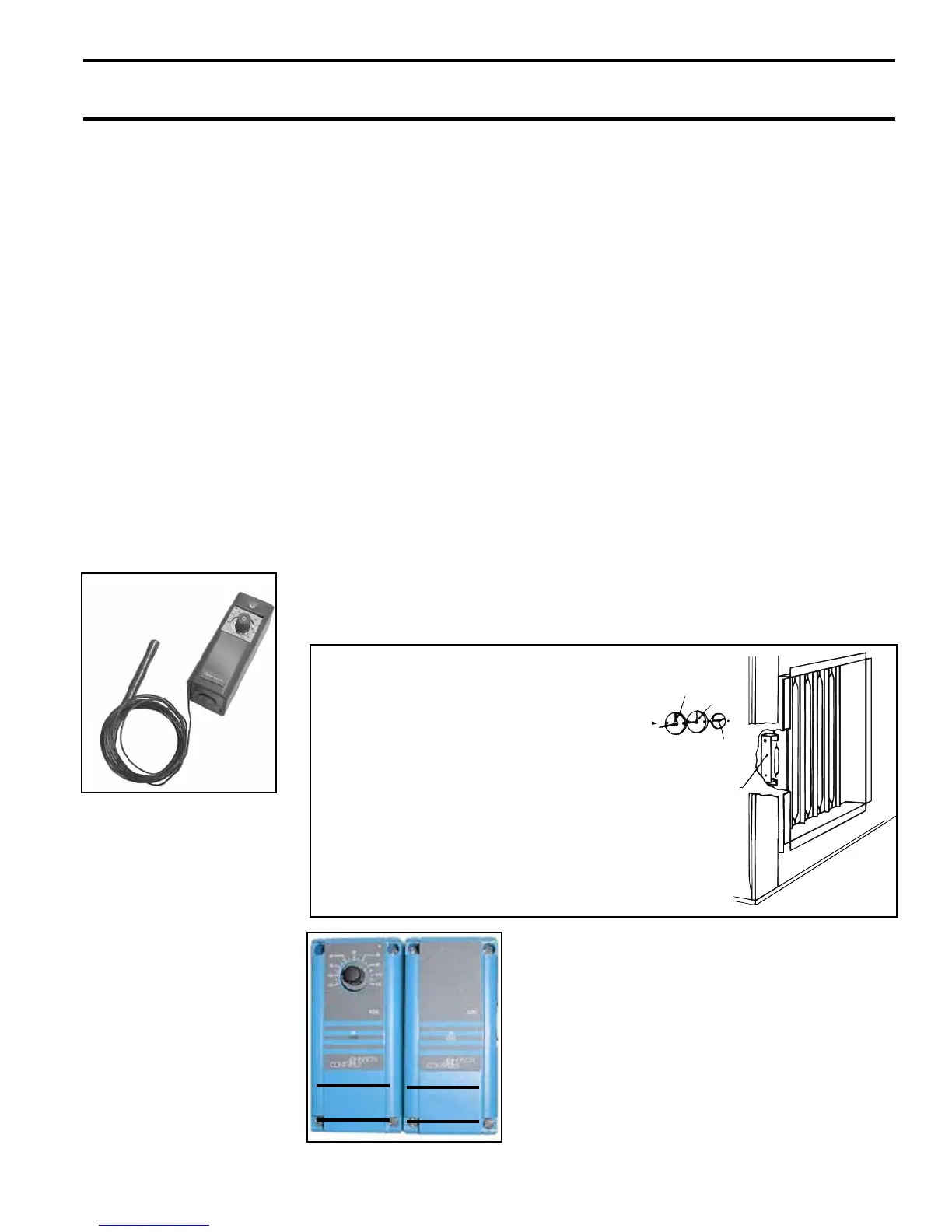

FIGURE 20 - Ductstat

Control in Two-Stage

Makeup Air Control

Option AG15 - (A)

Remote Temperature

Selector; (B) Stage-

Adder Module

(A)

(B)

Optional Ductstat with Electronic Remote Set-

point Module (Option AG15) - The sensing probe

is eld-wired to a remote temperature selector. The

temperature selector has an operating range to

120°F. The remote modules are shipped separately

for eld installation. Follow the wiring diagram with

the unit and the manufacturer's instructions for wiring

and installation.

There will be one module for selecting temperature

and one-stage adder module as illustrated in FIG-

URE 20.

Loading...

Loading...