Form I-X, P/N 150491 R7, Page 5

3.2 Preparing the

Furnace for

Installation

Read this booklet and become familiar with the installation requirements of your par-

ticular furnace. If you do not have knowledge of local requirements, check with the

local gas company or any other local agencies who might have requirements concern-

ing this installation. Before beginning, make preparations for necessary supplies, tools,

and manpower.

Check to see if there are any eld-installed options that need to be assembled to the

furnace prior to installation.

Option Parts -- Some gas control options will have parts either shipped loose with the

heater or shipped separately. If your unit is equipped with any of the gas control options

listed below, be sure these parts are available at the job site.

Application Option Shipped Separate Components

Heating -- Gas Control AG7 Thermostat, P/N 48033

Makeup Air -- Gas

Control Options

AG3, AG8 Control Switch, P/N 29054

AG9

Remote Temperature Selector, P/N 48042

Control Switch, P/N 29054

AG15

Remote Temperature Selector, P/N 115848

Stage Adder Module, P/N 115849

Control Switch, P/N 29054

Other shipped-separate options could include a vent damper, a power venter, a gas

shutoff valve, a condensate drain tting, a thermostat, and/or a disconnect switch.

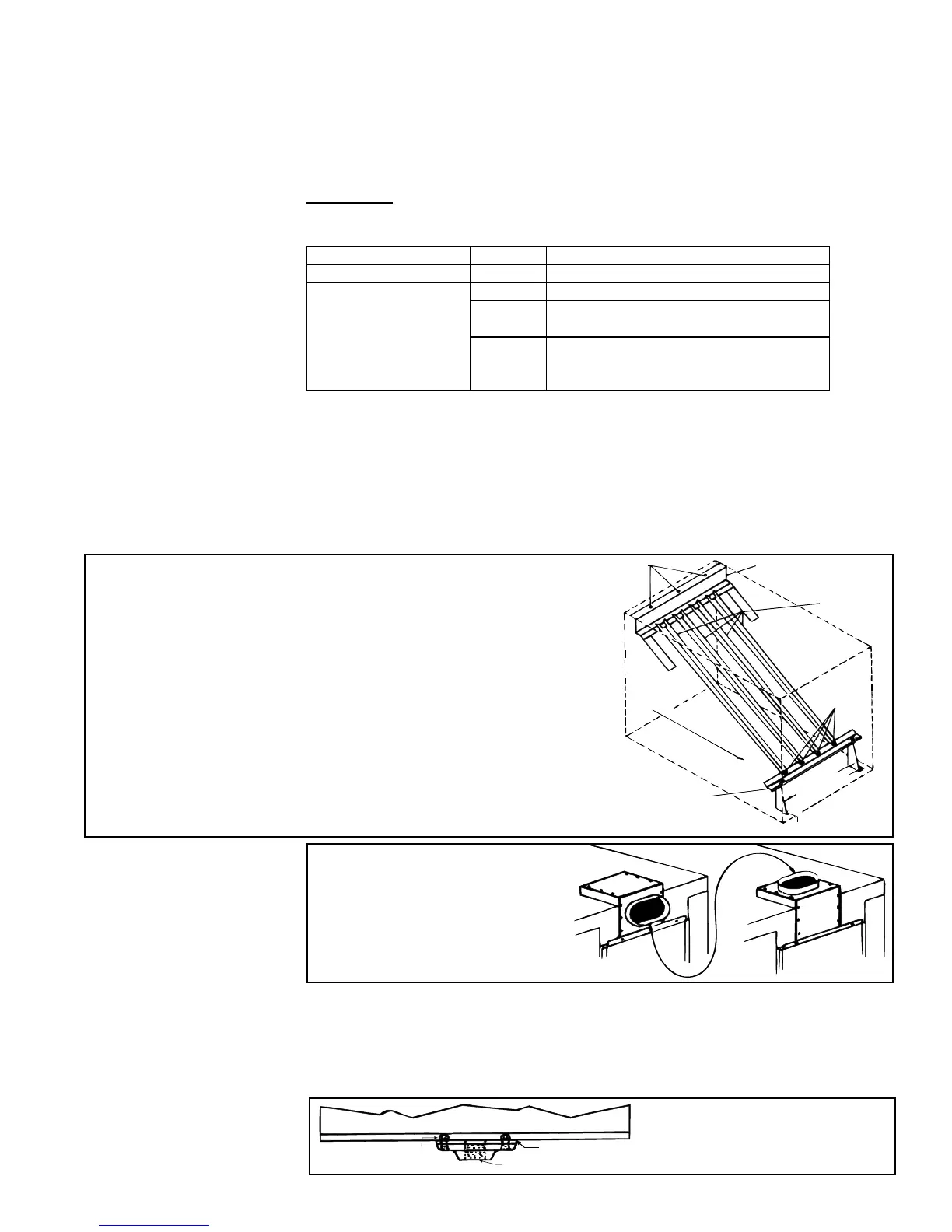

FIGURE 2 - Heat Exchanger Directional Air Bafes

Top Baffle

Support

Screws

B

Bottom

Baffle Support

Brackets

Air Discharge

Direction of Airflow

Screw C

Right

Left

Screws A

Screw C

Airflow

Baffles

3.2.1 Instructions for

Reversing Airow by

Changing Directional

Air Bafes in the Heat

Exchanger

Model X furnaces are equipped with directional air bafes between the heat exchanger

tubes. Facing the control compartment of the furnace, the standard direction of airow

is from left to right. An installation requiring direction of airow from right to left when

facing the control compartment requires repositioning of the directional air bafes at

the installation site. Follow the instructions in FIGURE 2 to change the position of

bafes:

a) Remove Screws "A". Individually lift each bafe slightly and slide

forward. Remove all bafes completely from the heat exchanger.

b) Remove Screws "B" and the top bafe support assembly.

Re-position the assembly to the opposite end of the heat

exchanger and attach.

c) Remove Screws "C" and the assembled bottom bafe support

and brackets. Plug the holes in the heat exchanger bottom by

re-inserting the screws in the holes. Position the assembly on

the opposite end of the heat exchanger and attach using eld-

supplied sheetmetal screws.

d) Re-install all of the individual bafes by reversing the procedure

in Step a) above.

3.2.2 Change the Vent

Outlet Direction

FIGURE 3 - Horizontal

or Vertical Flue

Connection

To change orientation (vertical

or horizontal) of the ue

connection: (1) Remove screws;

(2) Reverse position; (3) Re-fasten.

The vent outlet may be horizontal

or vertical.

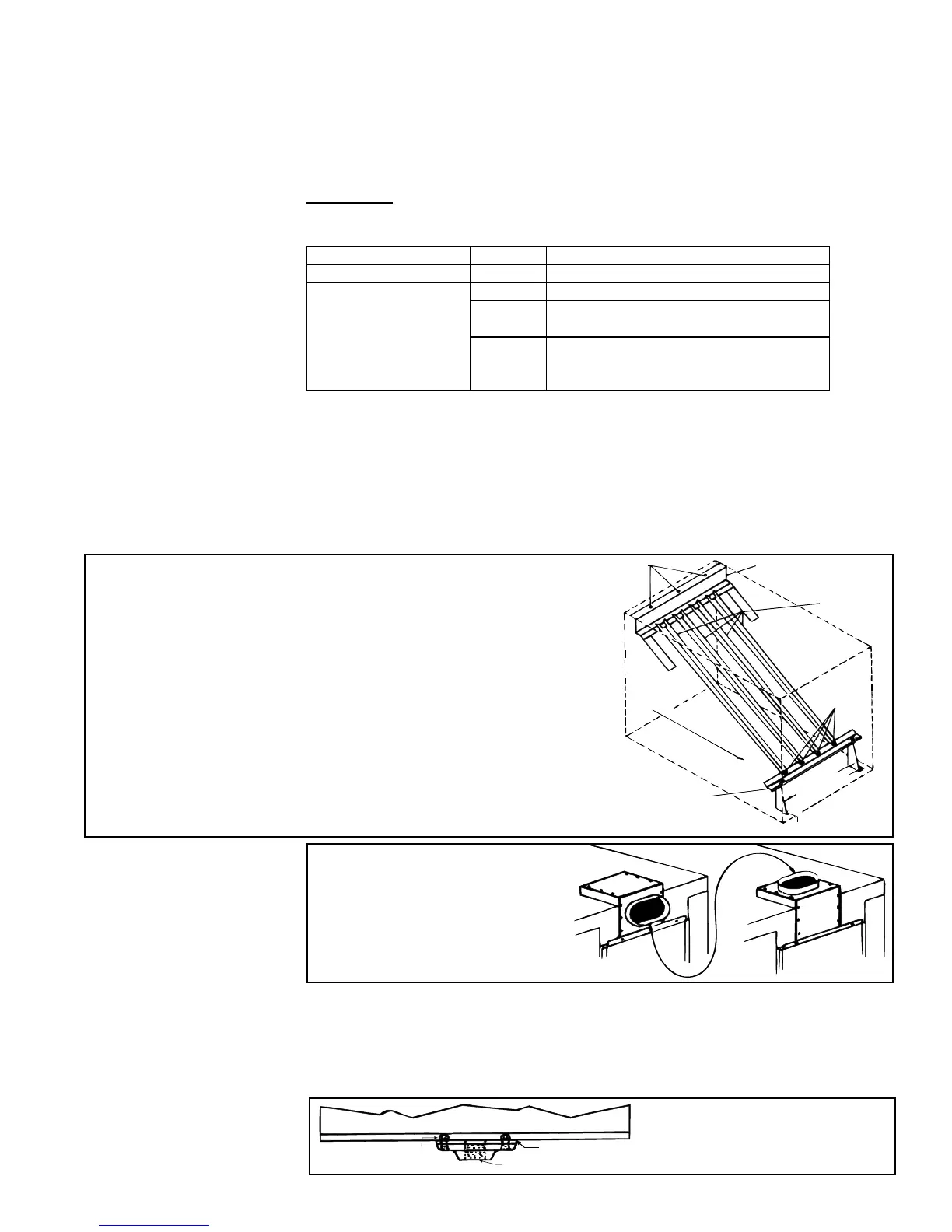

FIGURE 4 - Condensate

Drain, Option CS1

(P/N 31765)

Seal holes in bottom pan. Terminate

drain outside of building. Periodic

cleaning of the condensate collector

and disposal system is required.

3.2.3 Install

Condensate Drain,

Option CS1

Condensate can form in the heat exchanger of furnaces installed as makeup air units

or when installed downstream from a cooling coil. Under these conditions, a drain

ange, Option CS1, may be installed on the furnace bottom as shown in FIGURE 4.

When using Option CS1, seal all corners and the four square holes in the bottom pan

edge. NOTE: A 4-inch (102mm) minimum clearance is required under the furnace if a

90° street elbow is used.

Loading...

Loading...