15

COMBUSTION AND VENTILATION AIR (cont.)

For improved indoor air quality, added safety and product perfor-

mance we recommend direct vent type installations. If non-direct

type vent system is used, the requirements for combustion air

must be provided as identied in the National Fuel Gas Code.

Combustion air requirements are determined by whether the

furnace is in an open (unconned) area or in a conned space

such as a closet or small room.

FURNACE LOCATED IN AN

UNCONFINED SPACE

USING INDOOR AIR FOR COMBUSTION:

An unconned space must have at least 50 cubic feet for each

1,000 BTUH of total input for all appliances in the space. Table

1 below species minimum space requirements and a few ex-

amples of the room sizes required for different inputs. The sizes

are based on 8-foot ceilings.

If the open space containing the furnace is in a building with

tight construction, outside air may still be required for the fur-

nace to operate and vent properly. Outside air openings should

be sized the same as for a conned space.

FURNACE LOCATED IN A CONFINED

SPACE

A conned space is dened as any space for a given furnace

input rating which is smaller than that which is specied in Table

1 as minimum for an “unconned” space. If the space is less than

that specied in this table, the space is dened as “conned”.

If the space is small enough to be designated as “conned”,

it must have openings into the space which are located in ac-

cordance with the requirements set forth in the following sub-

sections A and B. Size connected to the heated area or to the

outside, and by the input of ALL appliances in the space.

If the conned space is within a building with tight construction,

combustion air must be taken from outdoors or from an area

freely communicating with the outdoors.

A. USING INDOOR AIR FOR COMBUSTION:

IMPORTANT: Air should not be taken from a heated space

with a replace, exhaust fan or other device that may pro-

duce negative pressure.

If combustion air is taken from the heated area, the open-

ings must each have at least 100 square inches of free

area. Each opening must have at least one square inch of

free area for each 1,000 BTUH of total input in the space.

Table 2 shows some typical examples of openings required

for combustion air openings required for a conned space.

B. USING OUTDOOR AIR FOR COMBUSTION:

IMPORTANT: Do not take air from an attic space that is

equipped with power ventilation.

The conned space must communicate with the outdoors in

accordance with Methods 1 or 2 below. The minimum dimen-

sion of air openings shall not be less than 3 inches. Where

ducts are used, they shall be of the same cross-sectional

area as the free area of the openings to which they connect.

METHOD 1:

Two permanent openings, one located within 12 inches of

the top and one located within 12 inches of the bottom of the

enclosure, shall be provided. The openings shall communi-

cate directly, or by ducts, with the outdoors or spaces (crawl

or attic) that freely communicate with the outdoors.

Combustion Air

COMBUSTION AIR REQUIREMENTS: CONFINED AND

UNCONFINED SPACES

!

WARNING

ALL FURNACE INSTALLATIONS MUST COMPLY WITH

THE NATIONAL FUEL GAS CODE, NFPA 54 AND LOCAL

CODES TO PROVIDE ADEQUATE COMBUSTION AND

VENTILATION AIR FOR THE FURNACE. FAILURE TO

DO SO CAN RESULT IN EXPLOSION, FIRE, PROPERTY

DAMAGE, CARBON MONOXIDE POISONING, PERSONAL

INJURY OR DEATH.

!

WARNING

READ AND FOLLOW THE GENERAL VENTING REQUIRE-

MENTS AND GUIDELINES OF THIS MANUAL FOR ADDI-

TIONAL VENTING REQUIREMENTS PERTAINING TO ALL

FURNACE INSTALLATIONS (INCLUDING DIRECT AND

NON-DIRECT VENTING). FAILURE TO FOLLOW ALL IN-

STRUCTIONS IN THIS MANUAL CAN RESULT IN EQUIP-

MENT FAILURE, EQUIPMENT DAMAGE, PROPERTY

DAMAGE, PERSONAL INJURY OR DEATH.

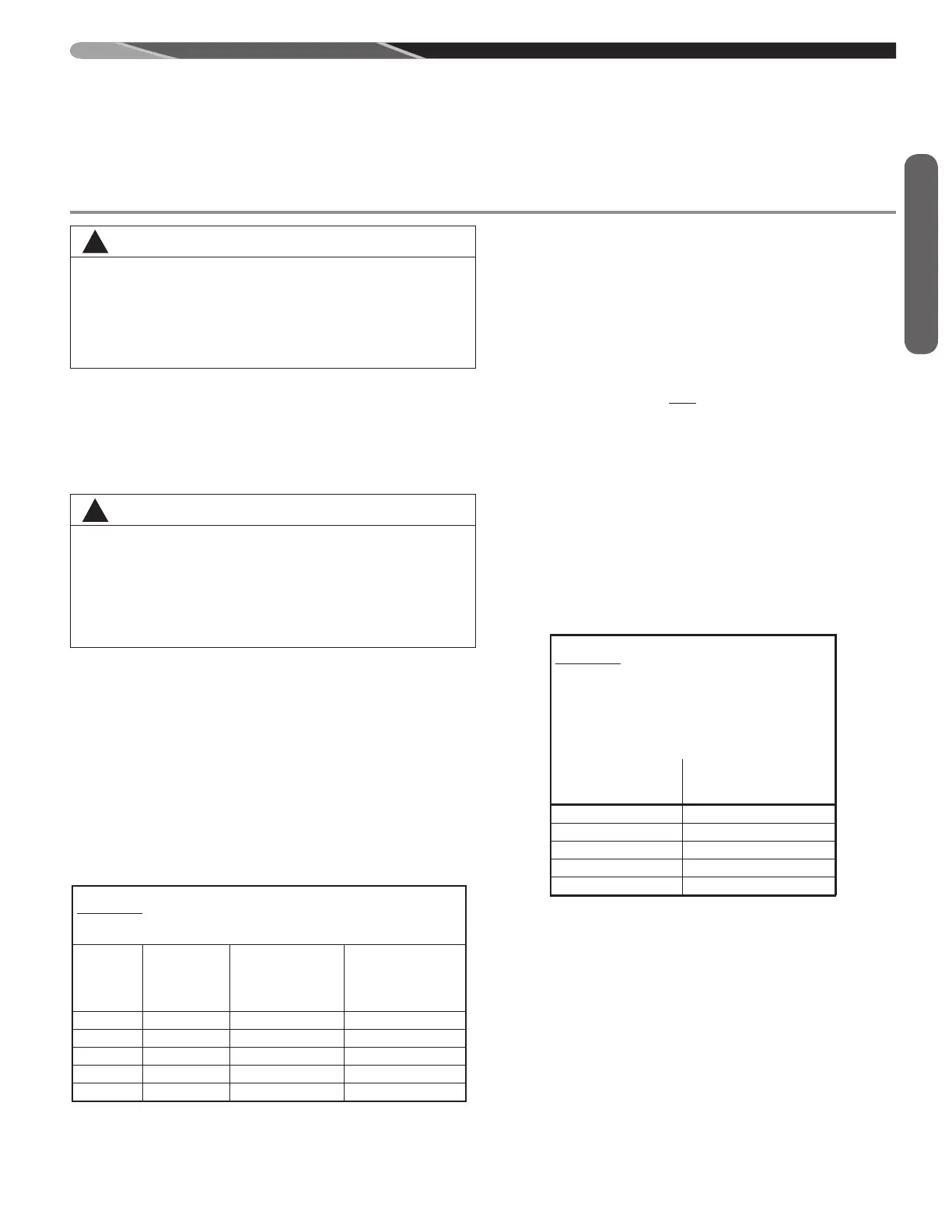

TABLE 7: MINIMUM SPACE REQUIREMENTS

FOR UNCONFINED SPACE, NON-DIRECT VENT*

Input

(BTUH)

Minimum

Space

(Cubic Ft)

Minimum Area

with 8

Ceilings (sq )

Typical Room

Size w/ 8'

Ceilings ( x )

50,000 2,500 313 16 x 20

75,000 3,750 470 24 x 20

100,000 5,000 625 32 x 20

125,000 6,300 790 36 x 30

150,000 7,500 940 32 x 30

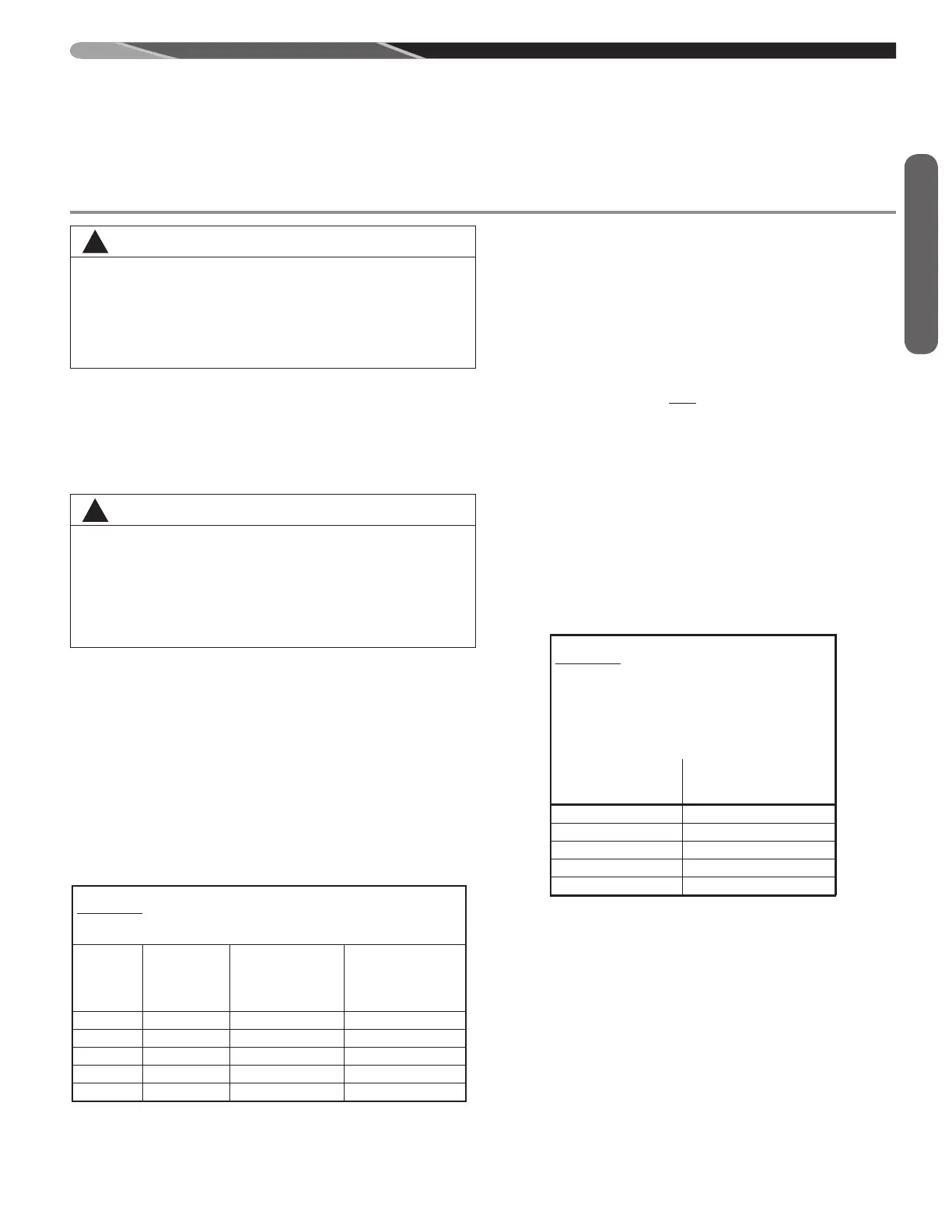

TABLE 8: MINIMUM FREE AREA

OPENING REQUIRED FOR A

FURNACE LOCATED IN A

CONFINED SPACE USING

INDOOR AIR FOR COMBUSTION.

Input (BTUH)

Free Area for Each

Opening (sq inches)

50,000 100

75,000 100

100,000 100

125,000 130

150,000 150

TABLE 1: MINIMUM SPACE REQUIREMENTS

FOR UNCONFINED SPACE, NON-DIRECT VENT

TABLE 7: MINIMUM SPACE REQUIREMENTS

FOR UNCONFINED SPACE, NON-DIRECT VENT*

Input

(BTUH)

Minimum

Space

(Cubic Ft)

Minimum Area

with 8

Ceilings (sq )

Typical Room

Size w/ 8'

Ceilings ( x )

50,000 2,500 313 16 x 20

75,000 3,750 470 24 x 20

100,000 5,000 625 32 x 20

125,000 6,300 790 36 x 30

150,000 7,500 940 32 x 30

TABLE 8: MINIMUM FREE AREA

OPENING REQUIRED FOR A

FURNACE LOCATED IN A

CONFINED SPACE USING

INDOOR AIR FOR COMBUSTION.

Input (BTUH)

Free Area for Each

Opening (sq inches)

50,000 100

75,000 100

100,000 100

125,000 130

150,000 150

TABLE 2: MINIMUM FREE AREA

OPENING REQUIRED FOR A

FURNACE LOCATED IN A

CONFINED SPACE USING

INDOOR AIR FOR COMBUSTION.

Loading...

Loading...