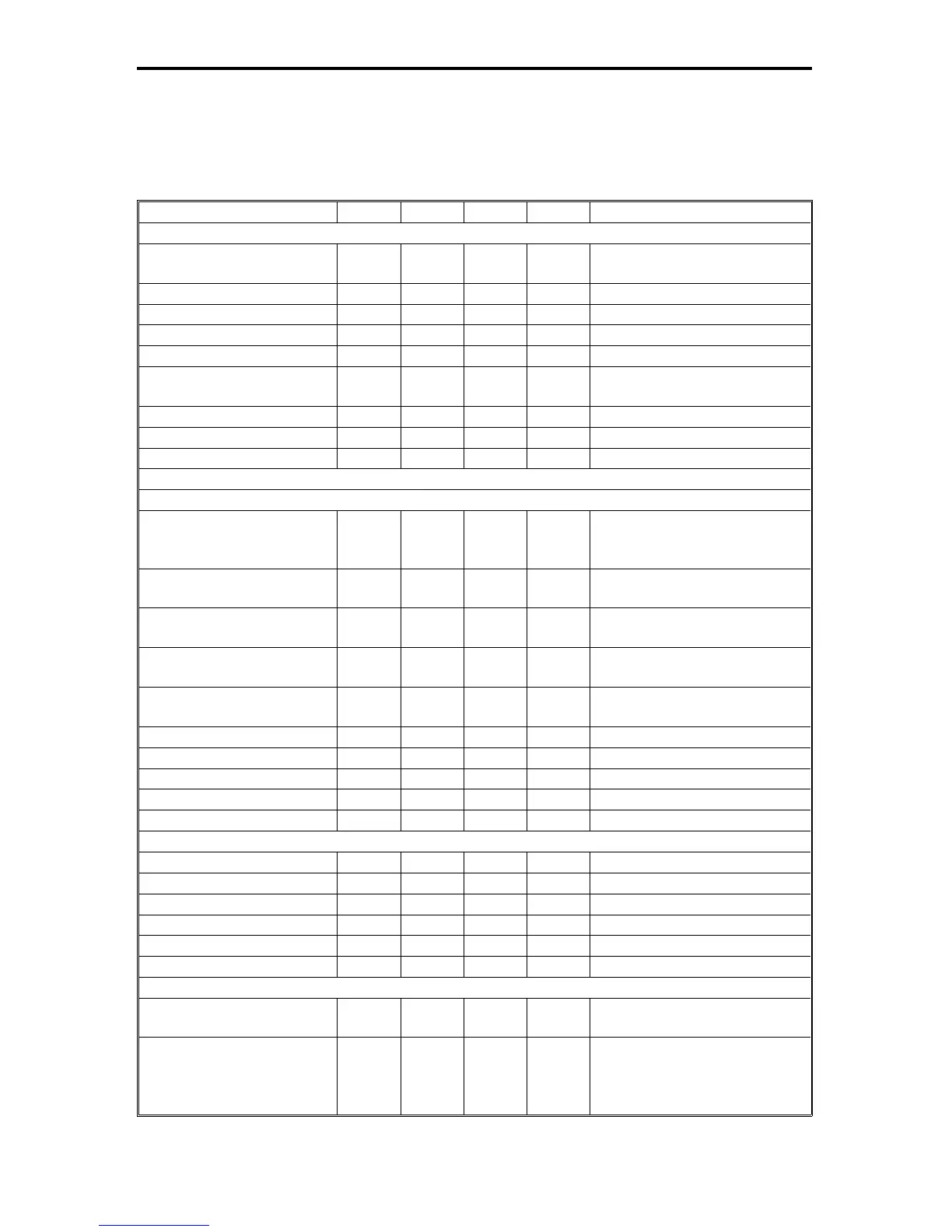

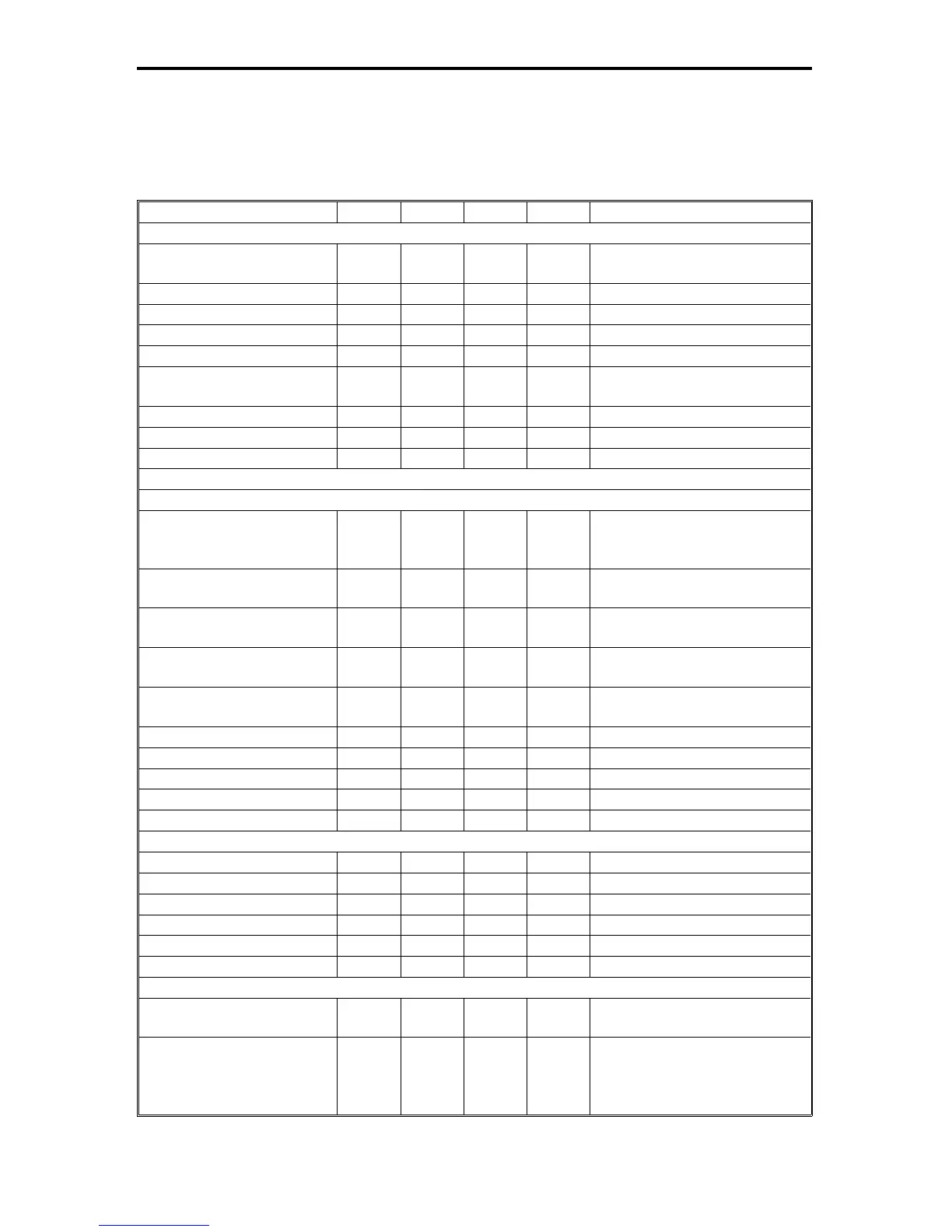

5. PREVENTIVE MAINTENANCE SCHEDULE

5.1 PM TABLE

NOTE: The amounts mentioned as the PM interval indicate the number of

copies.

Symbol key: C: Clean, R: Replace, L: Lubricate, I: Inspect

A153/A155/A156 EM 120K 240K 360K NOTE

OPTICS

Mirrors, Lens, Reflector C C C Cotton pad with water, or

blower brush.

Exposure Glass C C C C Alcohol or glass cleaner

Exposure Lamp IIIIReplace if necessary

Green Filter C C C Dry cloth

Scanner Guide Rails C C C Dry cloth

ADS, APS sensors C C C Blower brush. Do SP4-201

after cleaning the ADS sensor.

Lens Block Guide Rail C C C C Dry cloth

Toner Shield Glass C C C C Dry cloth

Dust Filter C C C Replace if necessary

NOTE: After cleaning the exposure lamp and/or optics, do SP4-001, then 4-201, then 3-105.

AROUND THE DRUM

Drum Charge Roller R R R Clean with the special cloth if

necessary (the cloth must be

dry)

Drum Charge Roller

Cleaner

R R R Replace with the drum charge

roller as a set.

Drum Charge Roller

Terminal

R R R Replace with the drum charge

roller as a set.

ID Sensor C C C Blower brush. After cleaning,

do SP3-001 then SP3-112.

Roller Terminal R R R Replace with the drum charge

roller as a set.

Erase Lamp C C C Dry cloth

Quenching Lamp C C C Dry cloth

Pick-off Pawls C R C Dry cloth

Pre-Transfer Lamp C C C Dry cloth and blower brush

DEVELOPMENT UNIT

Developer R R R Do SP2-214 after replacement.

Side Seal I I I

Development Filter R R R

Entrance Seal C C C C Replace if necessary

Toner Supply Unit C C C C Blower brush

PAPER FEED (for each paper feed station)

Pick-up, Feed, Separation

Rollers (Paper tray)

C C R C Clean with water. Replace

these rollers as a set.

Pick-up, Feed, Separation

Rollers (LCT,By-pass feed)

C C R C Clean with water. Replace

these rollers as a set.

Rev. 6/16/95

FT5535/4527/4522 4-54 FSM

Loading...

Loading...