20015900

12

GB

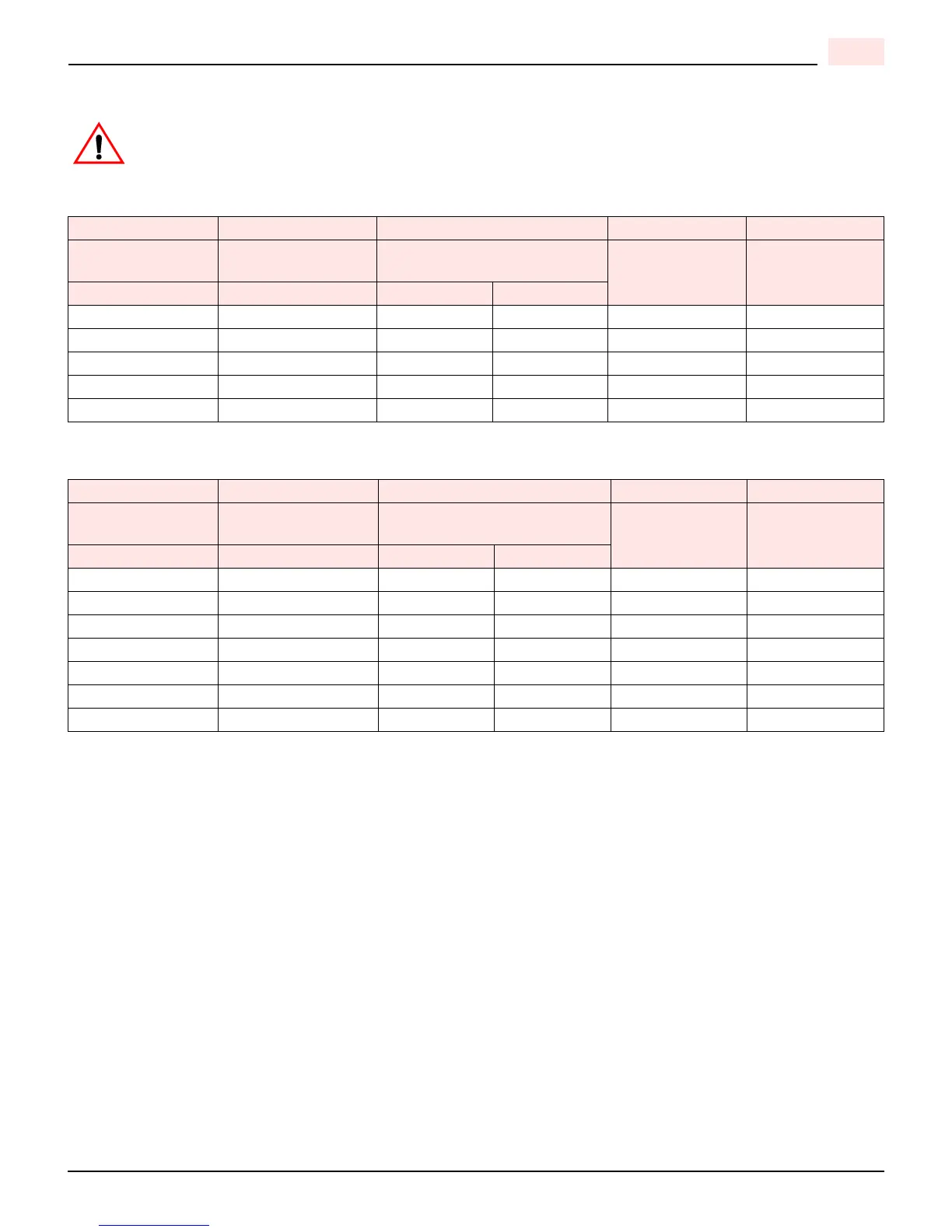

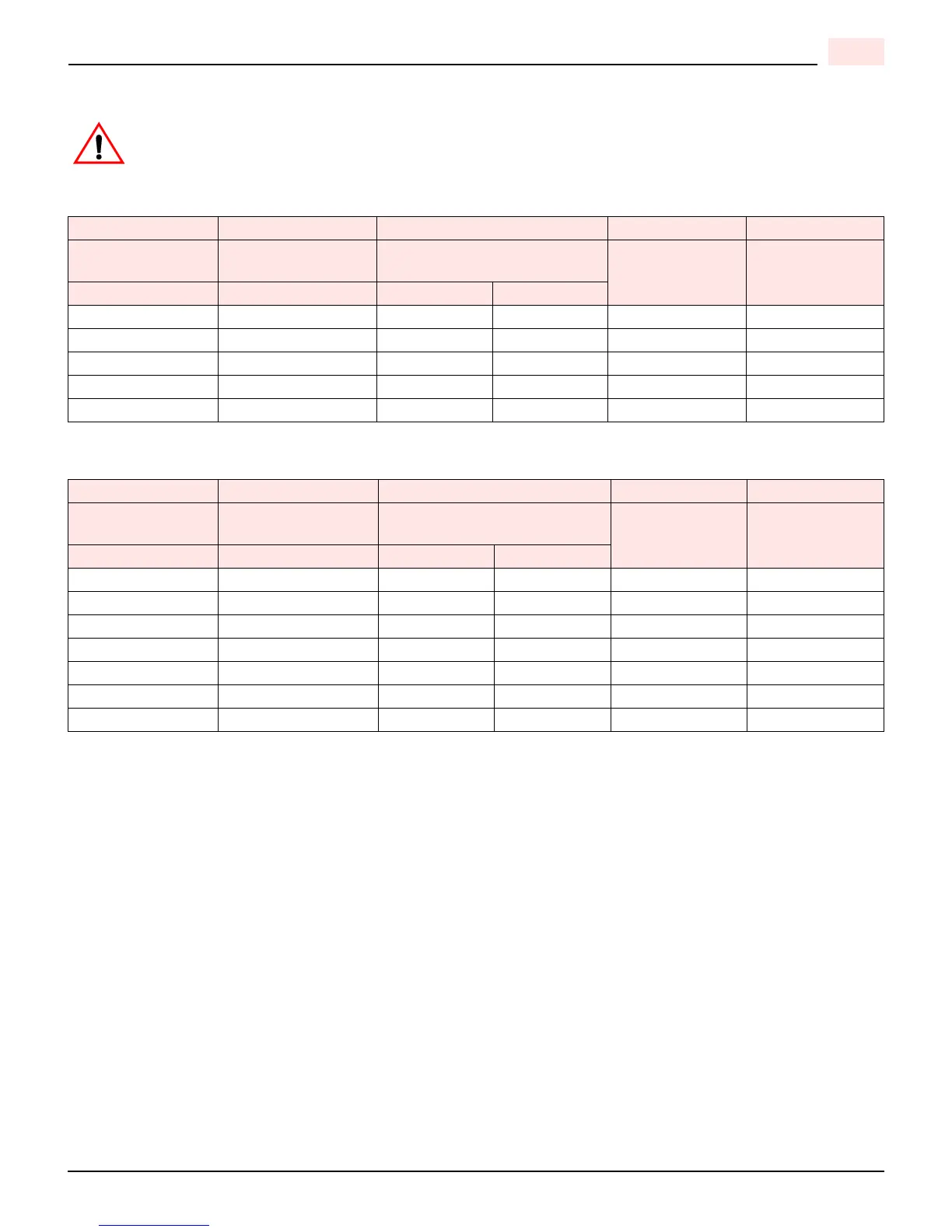

BURNER ADJUSTMENT TABLES

IMPORTANT

The following charts indicate initial setting with combustion air at 20ºC (68ºF).

MODEL BF3 BURNER SETUP CHART

MODEL BF5 BURNER SETUP CHART

- Actual input values given in above table are based on zero (0) chamber pressure, fired in Riello Canada Inc. Test

Lab DIN (small) test boiler (chamber length 17”, chamber diameter of 11”). Input values calculated using pump pres-

sures listed above in the set-up table. Some variations will occur depending on application. This above set-up table

is used to assist in the initial set-up only. Proper test equipment must be used to set the burner up properly.

- Please refer to appliance literature or recommendation regarding nozzle size, spray pattern and spray angle. If no

suggestions or literature are given, using above set-up table for desired input value set burner to table setting until

burner is firing then make suitable adjustments to burner to achieve desirable combustion results.

MODEL BF3 & BF 5 NOZZLES

Any nozzle manufacturer, size, and angle spray pattern. The appliance in which the burner is installed into determines

BF burner nozzle selection.

COMBUSTION CHAMBER

Follow the instructions furnished by the boiler/furnace manufacturer. Size retrofit application according to the

appropriate installation codes (e.g. CSA B139 or NFPA #31).

NON-RETROFIT APPLICATIONS

If this BF burner is packaged with the appliance, it is considered an OEM package; please read all instructions the related

to the burner, this information will supercede our installation manual.

1 2 3 4 5

ACTUAL FIRING

RATE 5% ±

NOZZLE SIZE PUMP PRESSURE

TURBOLATOR

SETTING

AIR DAMPER

SETTING

US GPH GPH PSI BAR

0.50 0.40 X 60/80° 160 11 0.0 3.2

0.60 0.50 X 60/80° 145 10 1.0 3.8

0.75 0.60 X 60/80° 160 11 1.5 4.4

0.80 0.65 X 60/80° 150 10 2.0 5.0

0.95 0.75 X 60/80° 160 11 3.0 7.0

1 2 3 4 5

ACTUAL FIRING

RATE 5% ±

NOZZLE SIZE PUMP PRESSURE

TURBOLATOR

SETTING

AIR DAMPER

SETTING

US GPH GPH PSI BAR

0.75 0.65 X 60/80° 145 10 0.0 3.3

0.85 0.75 X 60/80° 145 10 0.5 3.5

1.00 0.85 X 60/80° 145 10 1.0 4.0

1.10 1.00 X 60/80° 145 10 1.5 4.5

1.25 1.10 X 60/80° 145 10 2.0 5.0

1.50 1.25 X 60/80° 145 10 3.0 6.0

1.65 1.35 X 60/80° 145 10 4.0 7.0

Loading...

Loading...