Installation

20008423

21

4.7 Electrode positioning

Make sure that the electrode and the ignition pilot are positioned

as shown in figure (Fig. 15).

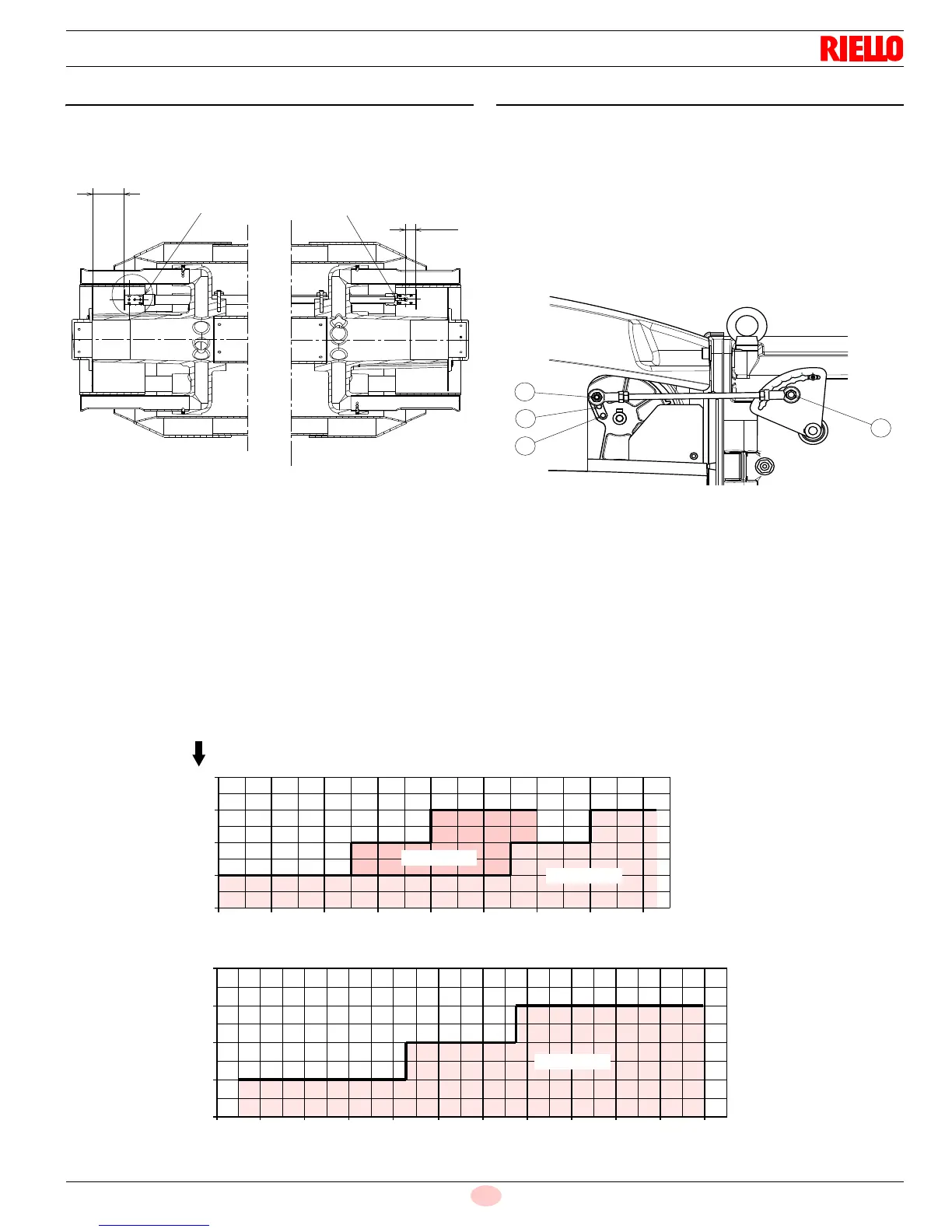

4.8 Combustion head setting

In addition to varying air flow depending on the output request-

ed, the air gate valve servomotor 4) (Fig. 5) by means of a lifting

assembly - varies the setting of the combustion head.

This system allows an optimal setting even at a minimum firing

rate.

For the same servomotor rotation, combustion head opening

can be varied by moving the tie rod onto holes 1-2-3, Fig. 16.

The choice of the hole (1-2-3) to be used is decided on the basis

of diagram (Fig. 17) against the required maximum output.

Setting is pre-arranged in the plant for the maximum run (hole 3)

(Fig. 16).

When dealing with boilers featuring a strong back pressure, if air

delivery is insufficient even with the damper fully open, you can

use a different setting to that illustrated in diagram (Fig. 17) do

this by moving the tie rod onto the next highest hole numerically

speaking, thus increasing the combustion head’s opening and

hence air delivery.

4

2

1

0

4545 6060 7575 9090 10605 12120 13635 15150 16664

3

2

1

0

9090 10605 12120 13634 15149 166644545 6060 7575

3030

3

4

MB t u / h r

18179 19694

MB t u / h r

Fig. 17

D9402

Max burner output

RS 400/E LN

RS 500/E LN

RS 300/E LN

N° Hole

Loading...

Loading...