20008423

23

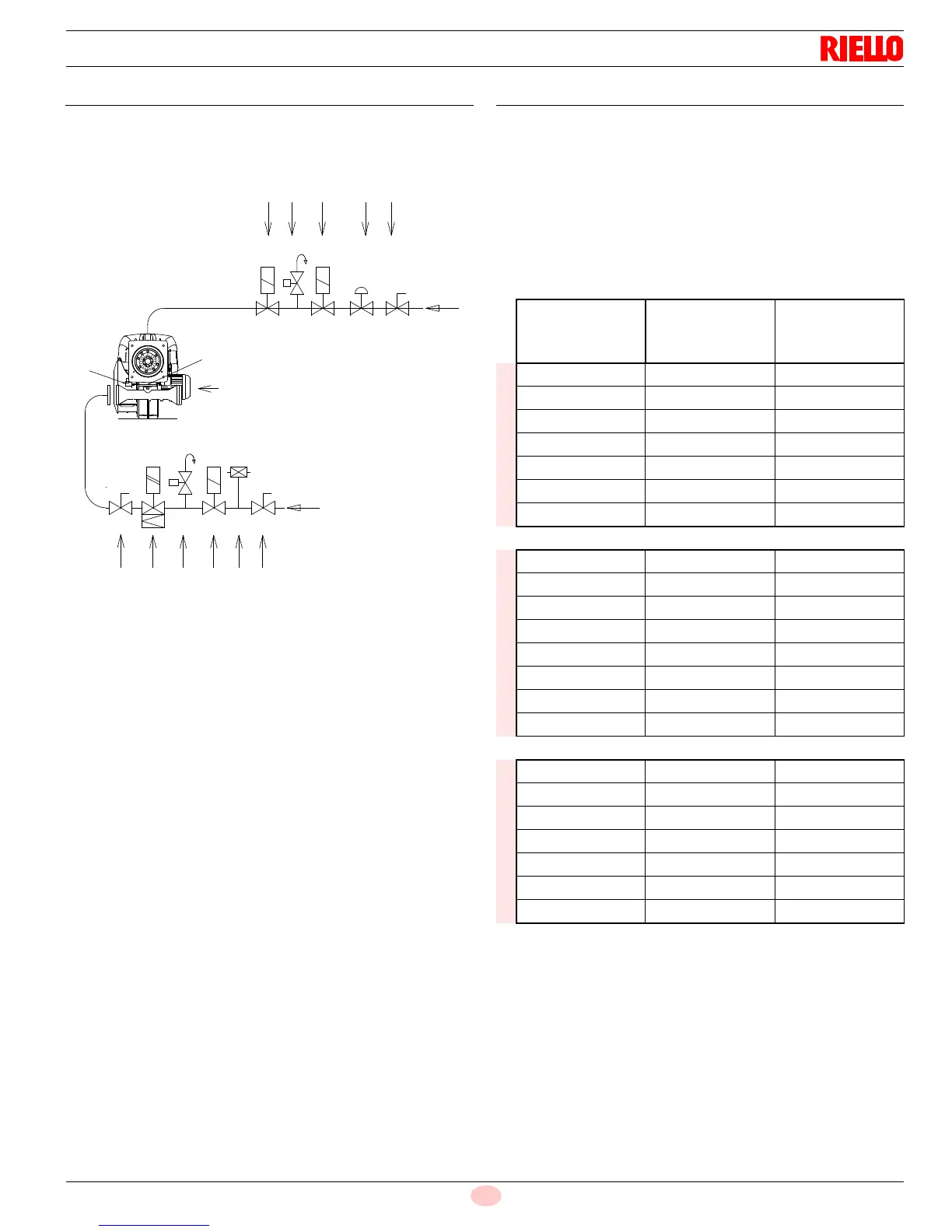

4.10.2 Gas feeding line

It must be type-approved according to required standards and is

supplied separately from the burner.

Key to lay-out (Fig. 20)

1 Gas input pipe for main burner

2 Manual valve

3 Low gas pressure switch

4 Safety shut-off valve

5 NO vent valve

6 Regulating shut off valve

7 Gas input pipe for pilot

8 Gas adjustment butterfly valve

9Burner

10 High gas pressure switch

11 Manual valve (for seal control)

12 Pilot regulator

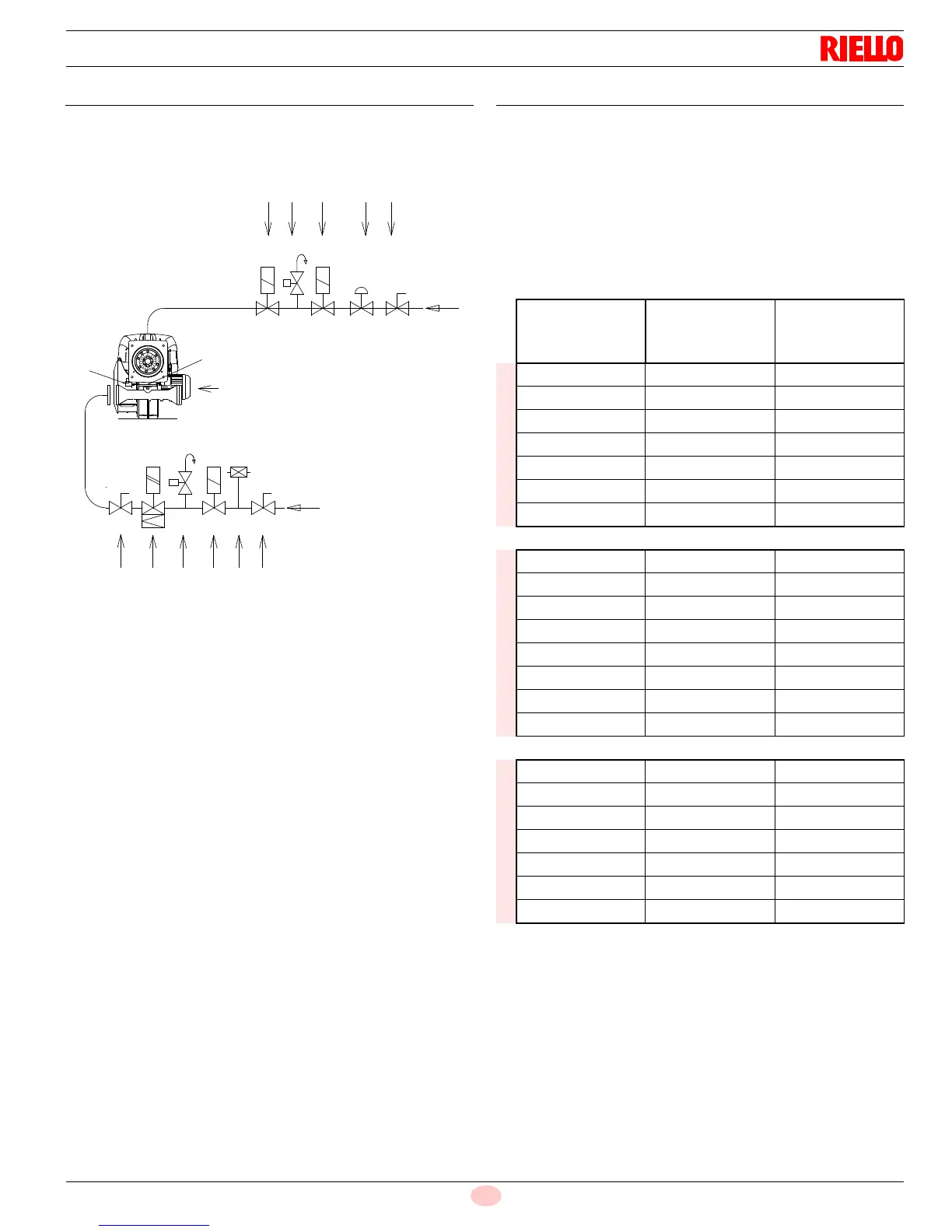

4.10.3 Gas pressure

Important

The pressure at the head of the burner from table refers to zero

in the combustion chamber; to obtain true pressure, measured

by a U-type manometer, (Fig. 36) add the counter-pressure of

the boiler.

Note

See the accompanying instructions for the adjustment of the gas

train.

212

5

4

4

GCV

MBtu/hr

Combustion

Head

“WC

Gas butterfly +

Adaptor

“WC

RS 300/E LN

5112 3.3 0.63

5680 3.7 0.79

7574 4.9 1.38

9467 5.4 2.13

11361 5.9 3

13254 7.9 4.2

14390 9 5.1

RS 400/E LN

6816 2.3 1.1

7574 3 1.38

9467 4.7 2.13

11361 6.4 3

12307 7.3 3.62

13254 8.3 5.17

15148 10.8 5.47

17042 13 7

RS 500/E LN

9467 4.4 1.81

11361 6 2.64

13254 7.7 3

15148 9.7 3.82

17042 11.8 4.64

18935 14.1 5.55

19692 15 5.9

Loading...

Loading...