BLOCKSYSTEM FS Pag. 35 Rev. 02 02/07

UK

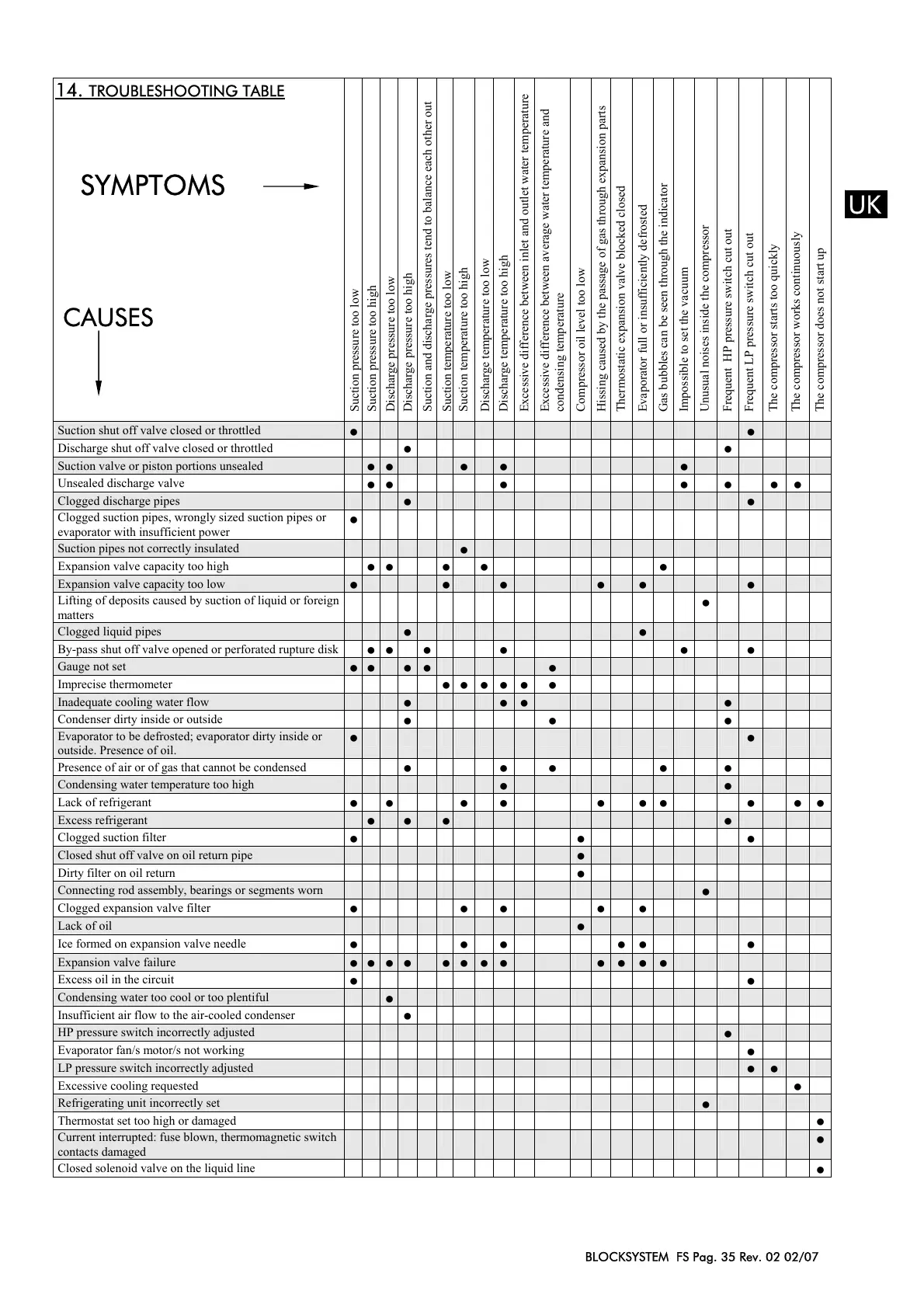

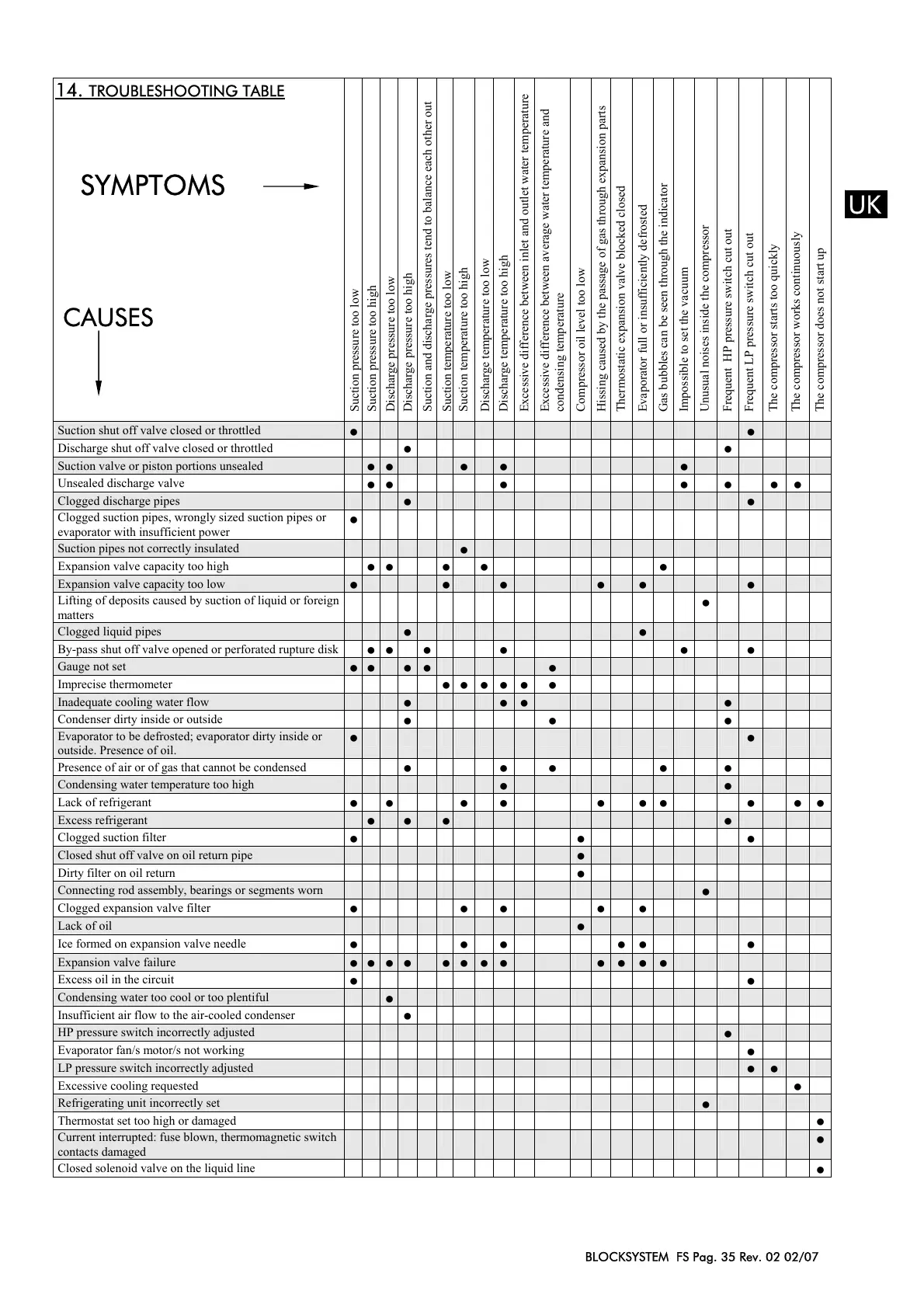

14. TROUBLESHOOTING TABLE

SYMPTOMS

CAUSES

Suction pressure too low

Suction pressure too high

Discharge pressure too low

Discharge pressure too high

Suction and discharge pressures tend to balance each other out

Suction tem

erature too low

Suction temperature too high

Discharge temperature too low

Discharge temperature too high

Excessive difference between inlet and outlet water temperature

Excessive difference between average water temperature and

condensing temperature

Compressor oil level too low

Hissing caused by the passage of gas through expansion parts

Thermostatic expansion valve blocked closed

Evaporator full or insufficiently defrosted

Gas bubbles can be seen through the indicator

Impossible to set the vacuum

Unusual noises inside the compressor

Frequent HP pressure switch cut out

Frequent LP pressure switch cut out

The compressor starts too quickly

The compressor works continuously

The compressor does not start up

Suction shut off valve closed or throttled

● ●

Discharge shut off valve closed or throttled

● ●

Suction valve or piston portions unsealed

● ● ● ● ●

Unsealed discharge valve

● ● ● ● ● ● ●

Clogged discharge pipes

● ●

Clogged suction pipes, wrongly sized suction pipes or

evaporator with insufficient power

●

Suction pipes not correctly insulated

●

Expansion valve capacity too high

● ● ● ● ●

Expansion valve capacity too low

● ● ● ● ● ●

Lifting of deposits caused by suction of liquid or foreign

matters

●

Clogged liquid pipes

● ●

By-pass shut off valve opened or perforated rupture disk

● ● ● ● ● ●

Gauge not set

● ● ● ● ●

Imprecise thermometer

● ● ● ● ● ●

Inadequate cooling water flow

● ● ● ●

Condenser dirty inside or outside

● ● ●

Evaporator to be defrosted; evaporator dirty inside or

outside. Presence of oil.

● ●

Presence of air or of gas that cannot be condensed

● ● ● ● ●

Condensing water temperature too high

● ●

Lack of refrigerant

● ● ● ● ● ● ● ● ● ●

Excess refrigerant

● ● ● ●

Clogged suction filter

● ● ●

Closed shut off valve on oil return pipe

●

Dirty filter on oil return

●

Connecting rod assembly, bearings or segments worn

●

Clogged expansion valve filter

● ● ● ● ●

Lack of oil

●

Ice formed on expansion valve needle

● ● ● ● ● ●

Expansion valve failure

● ● ● ● ● ● ● ● ● ● ● ●

Excess oil in the circuit

● ●

Condensing water too cool or too plentiful

●

Insufficient air flow to the air-cooled condenser

●

HP pressure switch incorrectly adjusted

●

Evaporator fan/s motor/s not working

●

LP pressure switch incorrectly adjusted

● ●

Excessive cooling requested

●

Refrigerating unit incorrectly set

●

Thermostat set too high or damaged

●

Current interrupted: fuse blown, thermomagnetic switch

contacts damaged

●

Closed solenoid valve on the liquid line

●

Loading...

Loading...