6-3

TIMING ADJUSTMENT

(See

Figs.

47,48

and

49)

The spark is timed to occur at

23”

before the piston reaches

TDC

on the compression stroke.

This

spark advance of

23”

is

controlled by the breaker point opening and tius advance is obtained when the breaker point opening is adjusted according

to

the

BREAKER

POINT ADJUSTMENT

to its proper point gpening. However, the advance timing is more accurately ad-

justed through the following procedures using a timing tester as

shown

in Fig.

48.

NOTE: Refer

to

section

“4-1’1

IGNITION”

and

“13.

CHECKS

and

CORRECTIONS.”

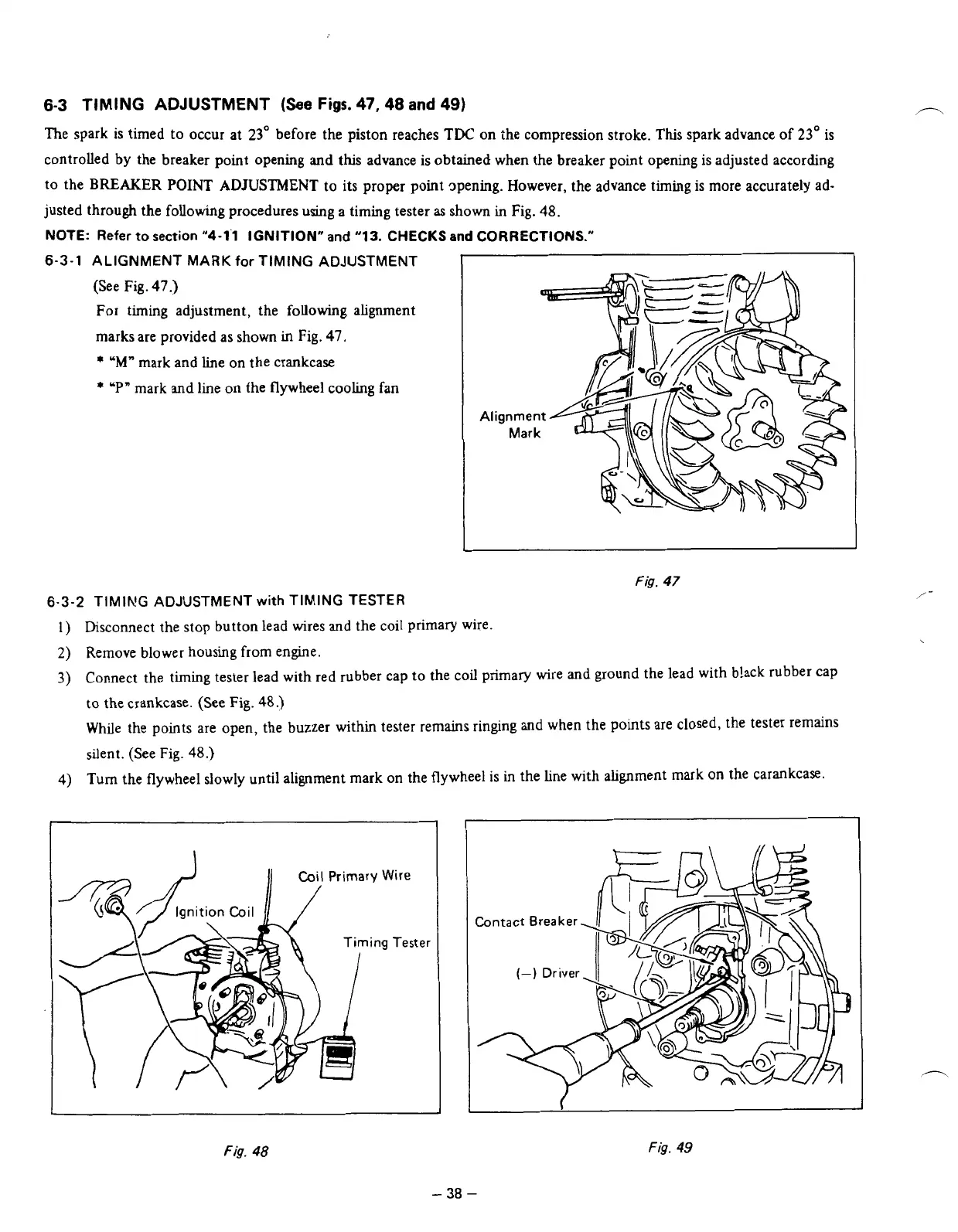

6-3-1

ALIGNMENT

MARK

for TIMING ADJUSTMENT

1

(See Fig.

47.)

For timing adjustment, the

following

alignment

marks are provided as shown

in

Fig.

47.

*

‘M”

mark and line on the crankcase

*

‘P-

mark and line on fhe flywheel cooling fan

Fig.

47

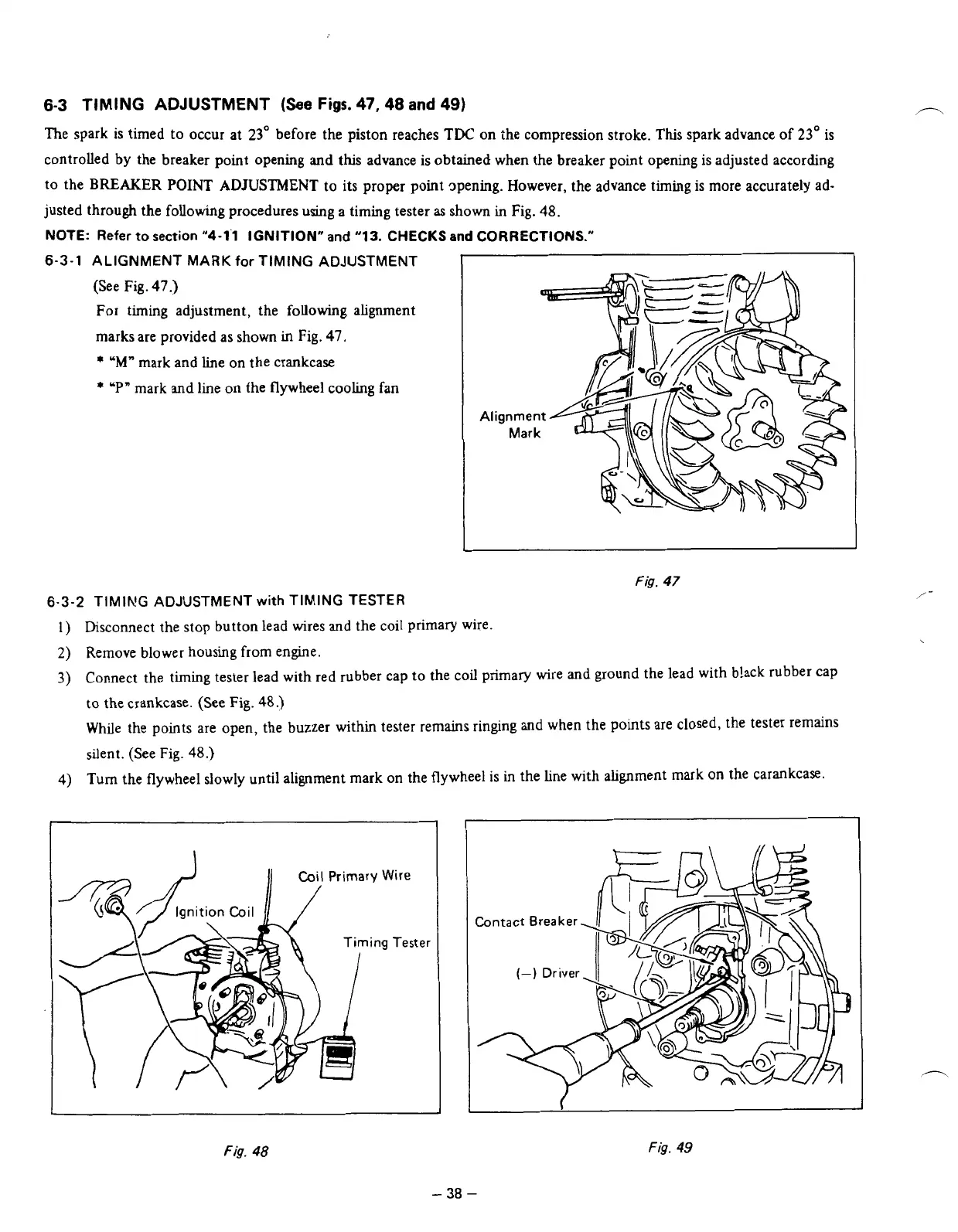

6-3-2

TIMING ADJUSTMENT

with

TIMING TESTER

1)

Bsconnect the stop button lead wires

and

the coil primary wire.

2)

Remove blower housing

from

engine.

3)

Connect the timing tester lead with red rubber cap

to

the coil primary wire and ground the lead with b!ack rubber cap

to

the crankcase. (See Fig.

48.)

While the points are open, the buzzer within tester remains ringing and when the

points

are closed, the tester remains

silent. (See Fig.

48.)

4)

Turn

the flywheel slowly until alignment mark on the flywheel is in the line

with

alignment mark on the carankcase.

Fig.

48

/-

Fig.

49

-

38

-

Loading...

Loading...