18

Changing and tensionning the belts

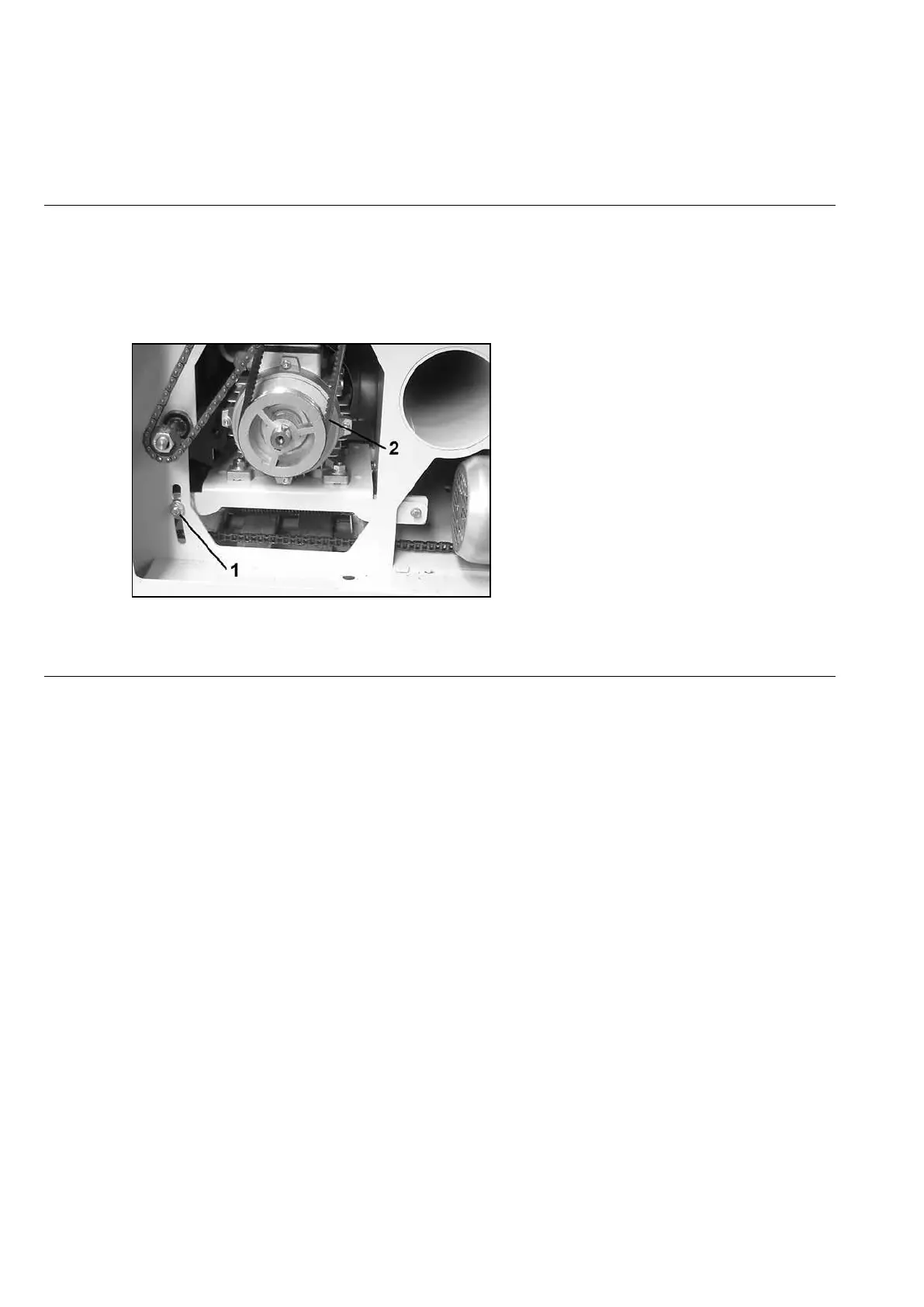

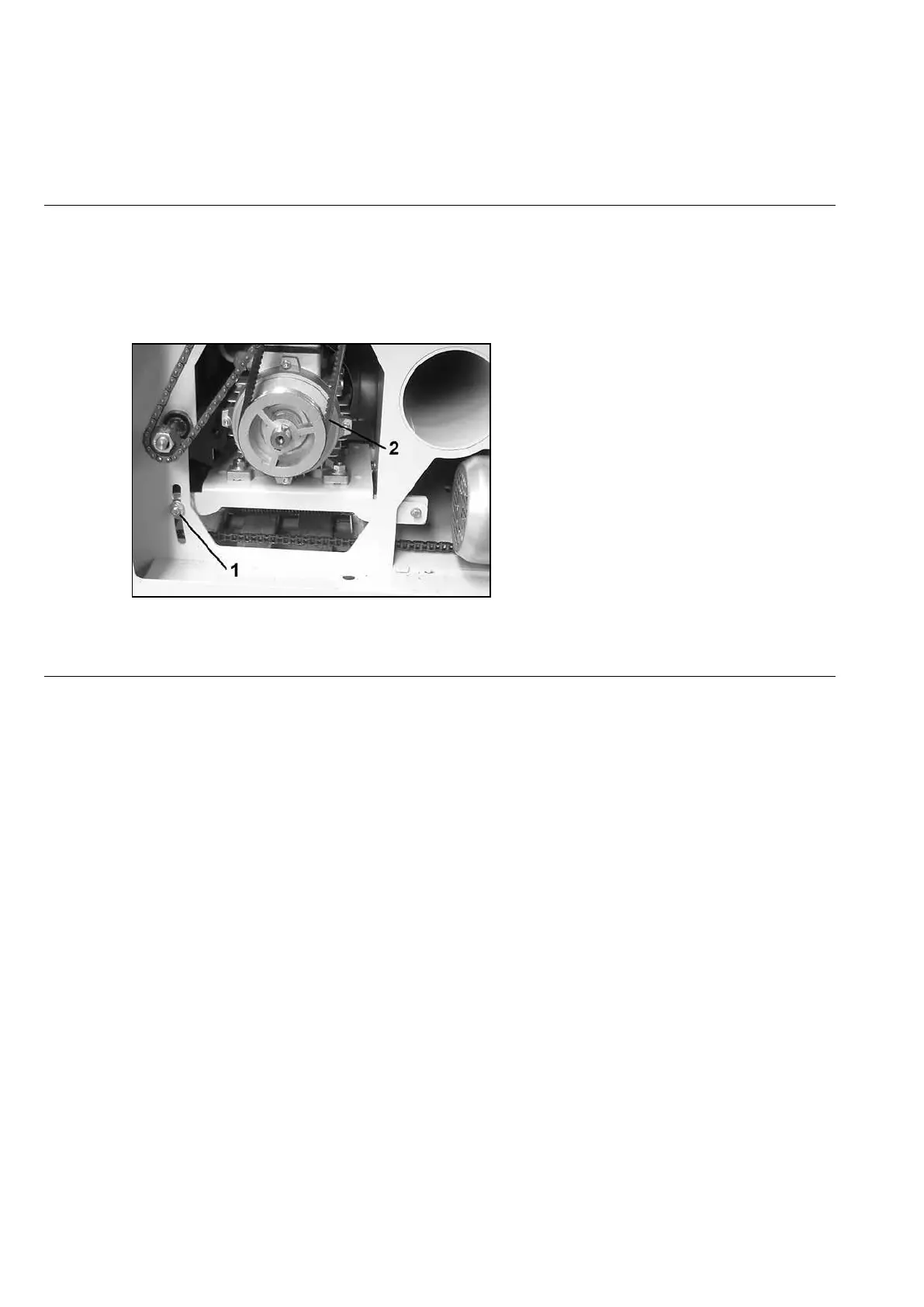

(Fig.15)

The belts of the motor can be tensionned as follows:

Unlock the bolt (1) which holds the motor mounting plate and push the motor down in order

to tension the belts and lock the bolt again.

Belt type: 13 x 1450 (A57)

Maintenance of the machine

Maintenance work should only be carried out by people who have the combination of

training, skills, experience and knowledge to do the work.

Always disconnect the machine from its power supply before starting all maintenance works!

The interior parts of the machine must be cleaned regularly to avoid an accumulation of dust

and woodchips.

All bearings inside the machine are double sealed and lubricated for life, therefore they need

no maintenance. These bearings are dust-tight, but thus, they are likely to become warmer

than normal ball bearings. There is nothing to worry about.

To guarantee a perfect functioning of the machine and prevent the formation of rust, the

moving parts of the machine need to be lubricated regularly, especially when the machine is

used in a humid environment or finishing wet wood.

The machine parts which need maintenance are the planer table hinges and axis. They must

be lubricated on a regular monthly base using a thin oil such as SAE30 or WD-40.

Any possible deposit of resin, on the various parts of the tables, must be taken away with a

piece of cloth and a little bit of solvent (petrol, kerosene or another product).

The worktables (upon which a workpiece rests or over which it passes) should be smooth

and free of any obstruction or damage that is likely to interrupt the continuous feeding of any

workpiece to the tool. The guards should be freely adjustable over the full range of work for

which they are designed, and continue to fulfil their safety function.

Never smoke or have any naked flame near the machine when using inflammable products,

avoiding the risk of fire and serious burns for the operator!

Additional measures of hygiene of the premises must be implemented as regular cleaning

the floor and the walls of the workshop (good housekeeping) using a suitable vacuum

cleaner adapted with an absolute filter (not of blower or broom which disperse the dust in the

Loading...

Loading...