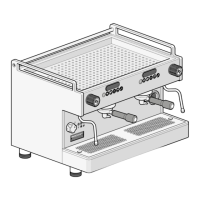

The Rocket RE DOPPIA Espresso Machine is a professional-grade coffee machine designed for brewing espresso, dispensing hot water, and steaming milk for hot beverages. It is available in 2, 3, and 4 group configurations, each equipped with a corresponding number of brewing heads and filter handles.

Function Description:

The primary function of the Rocket RE DOPPIA is to produce high-quality espresso with automatic portion control. It also provides hot water for other beverages and steam for frothing milk. The machine is designed for use in professional environments, emphasizing safety, durability, and hygienic operation.

Important Technical Specifications:

- Models: Rocket Espresso RE DOPPIA / 2 (2 brewing heads), Rocket Espresso RE DOPPIA / 3 (3 brewing heads), Rocket Espresso RE DOPPIA / 4 (4 brewing heads).

- Dimensions (Width x Depth x Height):

- 2 group: 760 mm (29.9 in) x 590 mm (23.2 in) x 536 mm (21.1 in)

- 3 group: 980 mm (38.6 in) x 590 mm (23.2 in) x 536 mm (21.1 in)

- 4 group: 1200 mm (47.2 in) x 590 mm (23.2 in) x 536 mm (21.1 in)

- Brew Boiler Capacity:

- 2 group: 4 liters

- 3 group: 6.3 liters

- 4 group: 8.5 liters

- Service Boiler Capacity:

- 2 group: 9 liters

- 3 group: 12 liters

- 4 group: 18 liters

- Water Inlet Pressure: Maximum 6 Bar (0.6 MPa – 600 KPa), minimum 1.5 Bar (0.15MPa-150 KPa). A pressure reducing valve is recommended if mains pressure is higher than 6 Bar.

- Hydraulic Connections: Water inlet 3/8" gas.

- Operating Temperature: The machine should not be operated in temperatures lower than 6°C (43°F) and hotter than 36°C (97°F).

- Water Quality: Requires soft, clean drinking water. An in-line filter and water softener are recommended to prevent mineral deposit buildup.

- Electrical Input: Machines with electrical input over 16 A must be connected to a net with impedance = or < than 0.37 Ω. A circuit breaker and a residual current device (RCD) with a rated residual operating current not exceeding 30mA must be installed.

- Ventilation: Requires an open area of at least 100 mm on each side and behind the machine for adequate ventilation.

- Minimum Installation Height: 1025 mm.

- Acoustic Noise: With normal use, the acoustic noise is 70 dB or lower.

Usage Features:

- Automatic Portion Control: The machine features touchpads with automatic coffee portion keys (available with 2 or 4 keys depending on the model) and hot water portion keys. These can be programmed to dispense specific quantities of coffee and hot water.

- Semi-automatic Dispensing: A "P" key allows for semi-automatic dispensing of espresso, where the user starts and stops the flow manually.

- Brewing Groups: Each brewing head (group) is designed for precise espresso extraction. The 4-group machines have two coffee boilers, with the left side controlled by the second group's touchpad and the right side by the third group's touchpad.

- Steam Wand: Used for frothing milk and heating liquids. It features a lever for steam control.

- Hot Water Wand: Dispenses hot water for various beverages.

- Pressure Gauges: Includes a pump pressure gauge (should be around 9 Bar) and a boiler pressure gauge (should be around 0.9 Bar) to monitor operation.

- Display: An LCD display provides information, including technician's menu settings.

- Boiler Water Level Control: Ensures proper water levels in the boiler.

- Included Accessories: User instructions, one-cup filter handle, one-cup metal filter basket, blind filter basket (for cleaning), bottomless filter holder. Two-cup filter handles and baskets are included based on the machine's group configuration.

Maintenance Features:

- Daily Cleaning:

- Wipe steam wand immediately after each use with a damp, non-abrasive cloth.

- "Burp" the steam wand by opening and closing the steam lever to remove milk residue.

- Knock used coffee grounds from the filter holder and rinse.

- Wipe screens inside the group head with a damp clean towel.

- Nightly Cleaning (Before Shutting Down):

- Rinse the brewing head by scrubbing with a small hard brush.

- Backflush the group regularly using a blind filter basket and special detergent for espresso machines. This can be done manually (pressing "P" key and switching off after 15 seconds) or automatically (pressing "P" and "I" keys simultaneously).

- Clean showers, group gaskets, and group flange with a clean brush.

- Clean filter holders and metal filter baskets, removing coffee oils. Soaking in hot water with detergent may be necessary for excessive buildup.

- Clean the drip tray and grid with a non-abrasive damp cloth.

- Clean the drain tray (located under the drip tray) with a damp cloth and brush.

- General Maintenance:

- Wipe down the machine surface with a non-abrasive clean cloth.

- Before any cleaning or maintenance, switch off the machine, disconnect from the electric supply, and allow it to cool.

- For long periods of non-use, completely drain the hydraulic systems and store the machine above freezing temperatures (0°C or 32°F) to prevent damage.

- Installation and technical service must be carried out by authorized Rocket Espresso Ltd. technicians.

- Only original Rocket Espresso Ltd. components should be used for spare parts.

- Technician's Menu: An advanced menu accessible by authorized technicians for configuring various parameters such as language, service phone, group numbers, boiler settings, crono function, LED idle, keyboard type, filling-up+coffee, doses setting, continuous key, tea+pump, prebrewing, probe sensitivity, service cycles, boiler probe pressure, temperature, PID settings, and offsets.

Loading...

Loading...