Issue 1 Original Version October 2014

18

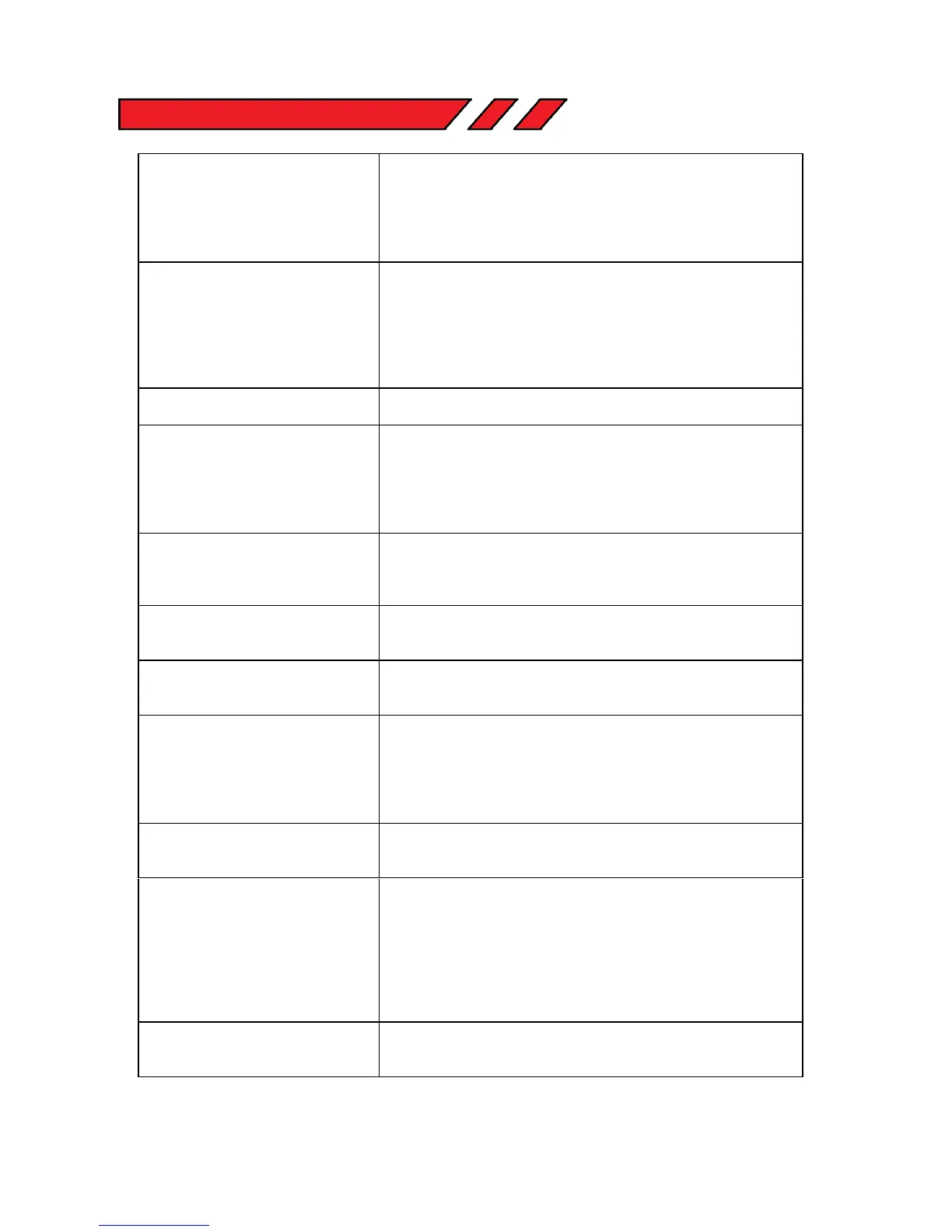

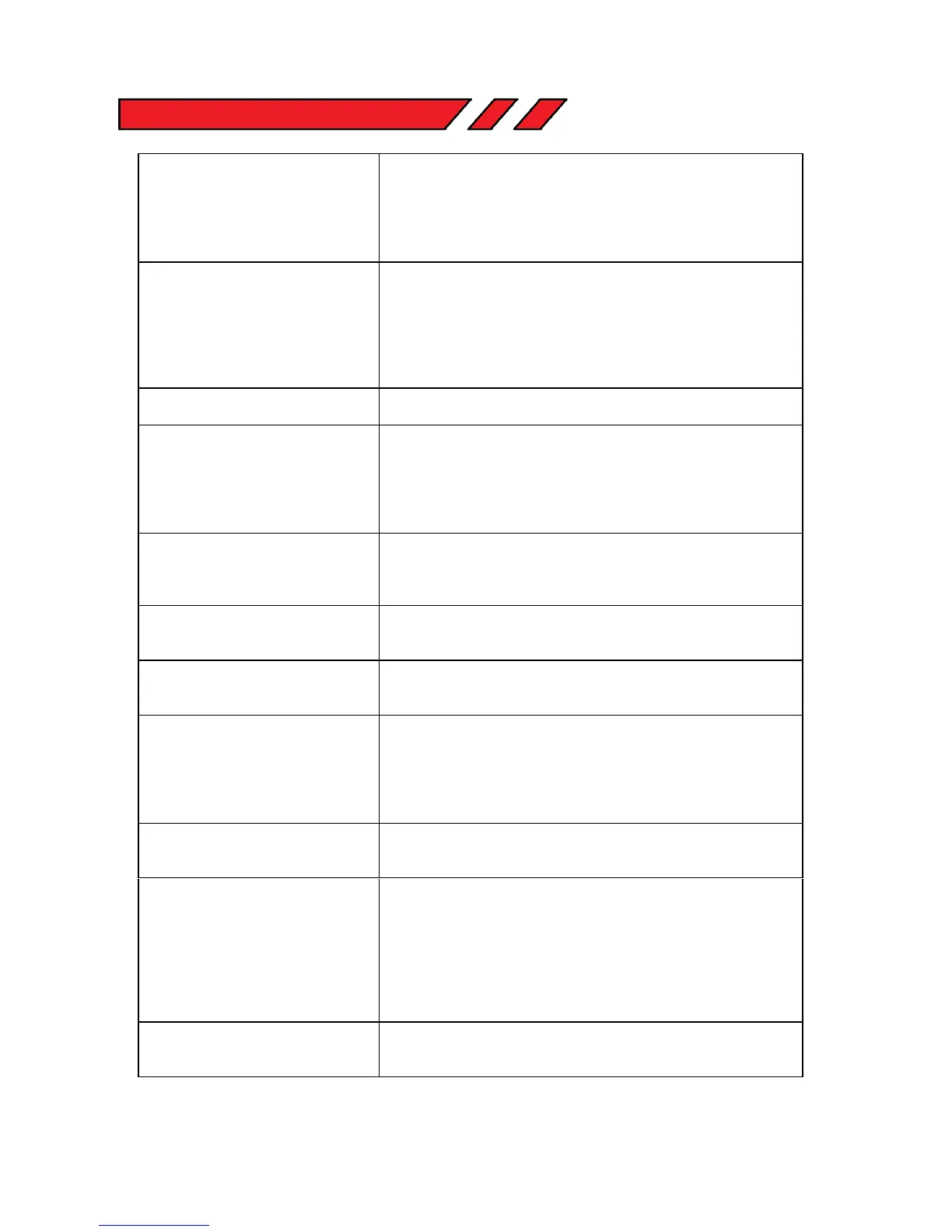

Magnet and motor do not function

- The magnet switch is not connected to the power supply

- Damaged or defective wiring

- Defective fuse

- Defective magnet switch

- Defective control unit

- Defective power supply

Magnet does function, the motor

does not

- Damaged or defective wiring

- Carbon brushes are stuck or worn out

- Defective magnet switch

- Defective on / off switch

- Defective Control Unit

- Defective armature and/or field

- Defective magnet protective switch

Magnet does not function, the motor

does

Hole cutters break quickly, holes are

bigger than the hole cutter

- Bent spindle

- Defective magnet causing movement

- Shaft extending from the motor is bent

- Uneven work surface causing lack of magnetic adhesion.

- Bent pilot

Motor running roughly and/or seizing

up

- Shaft extending from the motor is bent

- Triangular guide not mounted straight

- Dirt between spindle and triangular guide

Motor making a rattling sound

- Gear bearing (bottom of the armature) worn out

- Gear(s) worn out

- No grease in gear box

Motor humming, big sparks and

motor has no force

- Field burned

- Carbon brushes worn out

Motor does not start or fails.

- Damaged or defective wiring

- Dirt in sensor of speed control unit

- Defective speed control unit

- Defective speed control or its wiring

- Defective or loose magnet on top of armature

- Damaged or defective brushes

Guiding takes a great deal of effort

- Guide is dry

- Guide/gear- rack/rotation system dirty or damaged

Insufficient magnetic force

- Damaged or defective wiring

- Bottom of magnet not clean and dry

- Bottom of magnet not flat

- Work piece is not bare metal

- Work piece is not flat

- Work piece is too thin less than 10mm

- Defective control unit

- Defective magnet

Motor only runs at maximum rpm

- Damaged / defective wiring

- Defective control unit

- Damaged / defective wiring

- Defective magnet

- Motor seriously dirty

Loading...

Loading...