10

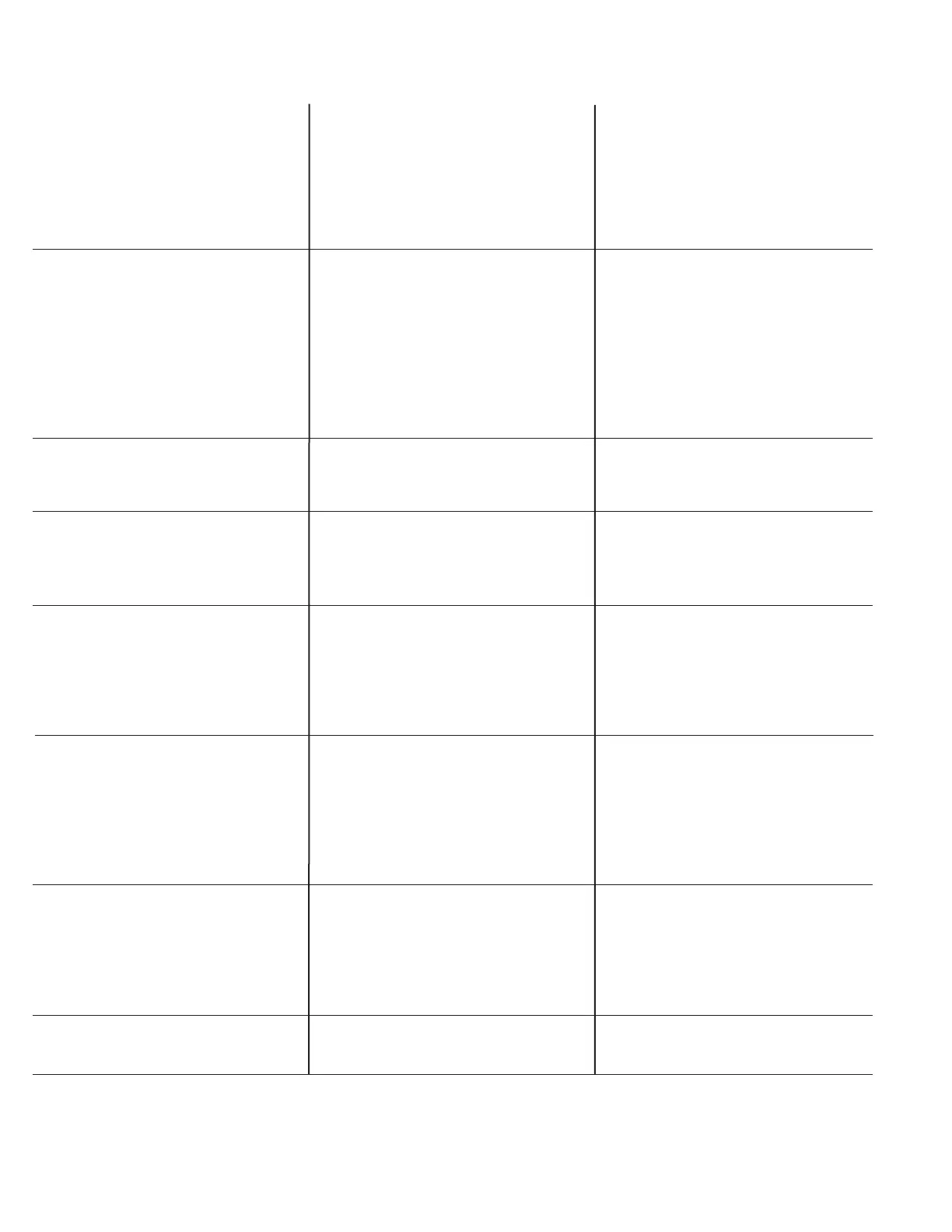

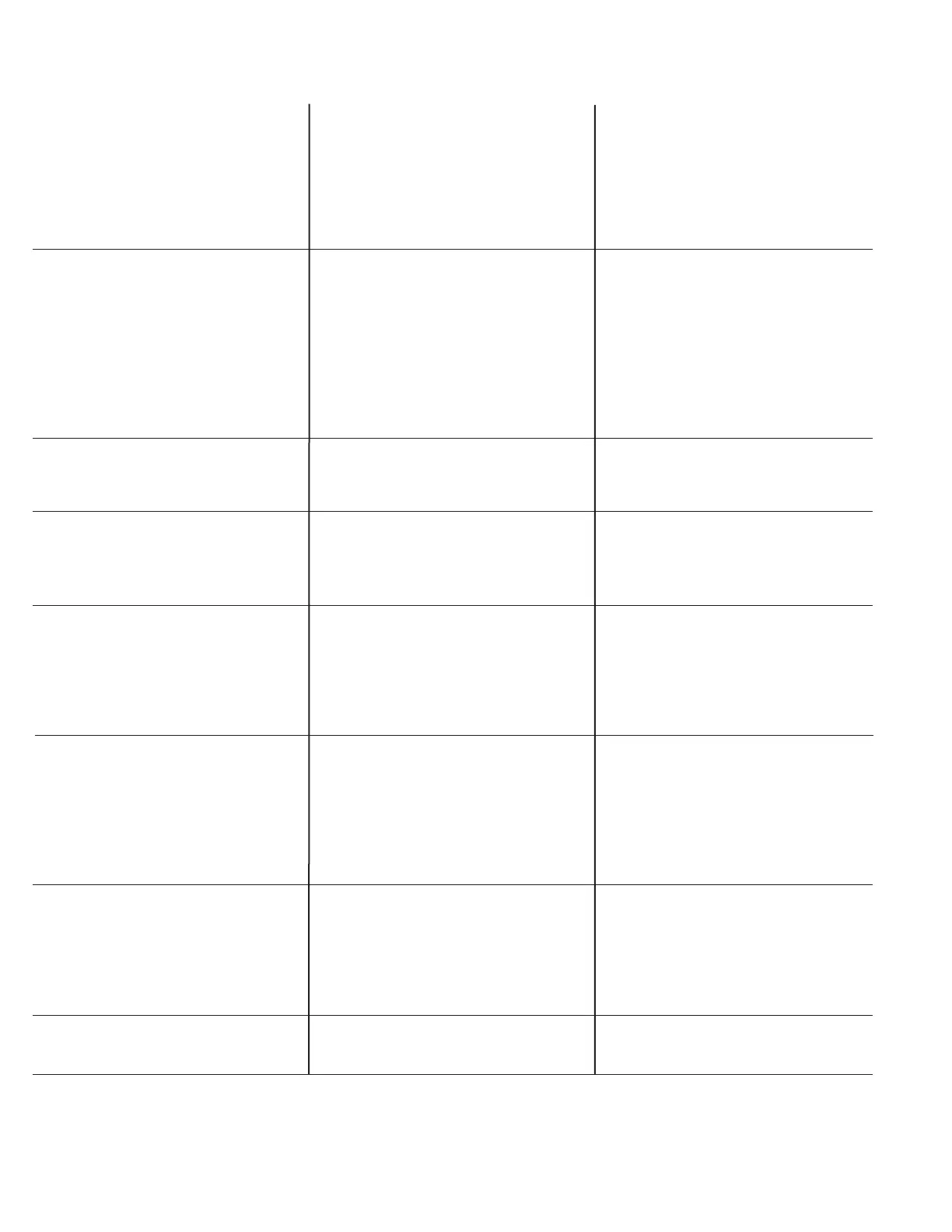

TROUBLE SHOOTING FOR AUTHORIZED MAINTENANCE PERSONNEL

Cause

1. Incorrectvoltagetomotor.

2. Bad wiring connections.

3. Motorupswitchburnedout.

4. Overheadlimitswitchburnedout.

5. Motorwindingsburnedout.

1. Overloading lift

2. Motorrunningonlowvoltage

3. Debrisinloweringvalve

4. Pumpsuckingair

5. Suctionstuboffpump

6. Low oil level

7. Improperreliefvalveadjustment

1. Debrisincheckvalveseat.

2. Debrisinloweringvalveseat.

3. External oil leaks.

1. Airmixedwithoil.

2. Airmixedwithoilsuction.

3. Oil return tube loose.

1. Equalizercablesoutofadjustment.

2. Liftinstalledonunleveloor.

1. Holesdrilledoversize.

2. Concreteoorthicknessorholding

strengthnotsufcient.

1. Low oil level

2. Air in hydraulic lines/cylinder

1. None

Remedy

1. Supplycorrectvoltagetomotor.

2. Repair and insulate all connections.

3. Replace switch/controls.

4. Replaceoverheadlimitswitch.

5. Replacemotor.

1. Check vehicle weight and/or balance

vehicle weight on lift

2. Supplycorrectvoltagetomotor

3. Clean lowering valve

4. Tightenallsuctionlinettings

5. Replace suction stub

6. Fill tank to proper level with ISOVG32

hydraulicoilorDexronIIIATF

7. Replacereliefvalvecartridge.

1. Clean check valve.

2. Clean lowering valve.

3. Repair external leaks.

1. ChangeoiltoDexronIIIATF

or ISOVG32.

2. Tightenallsuctionlinettings.

3. Reinstall oil return tube.

1. Adjustequalizercablestocorrect

tension.

2. Shimlifttolevelcolumns(Notto

exceed13mm).Ifover13mm,break

outoorandlevelperliftinstallation

instructions.

1. Relocate lift using new bit to drill holes.

Reference installation instructions for

properanchoringmethodandminimum

spacingrequirements.

2. Break out old concrete and re-pour

new pads for lift per lift installation

instruction.

1. FilltanktoMIN___markwith

ISOVG32hydraulicoilorDexronIIIATF.

2.Startunit,raiseliftabout610mm.Open

cylinderbleedersapproximately2

turns.Closebleederswhenuid

streams.Lowerliftandlltank.

1. None,thisisnormal.

Trouble

Motordoesnotrun.

Motorrunsbutwillnotraiselift

Lift slowly settles down.

Slowliftingspeedoroilblowingoutller

breather cap.

Lift going up unlevel.

Anchors will not stay tight.

Lift stops short of full rise or chatters.

Lockinglatchsolenoidsgetextremelyhot

when lift is being lowered.

Note: Shimthicknessof51mmispossiblebyusingoptionalshimkit#FC5393.ContactyourauthorizedRotaryrepairperson.

Loading...

Loading...