12

15. Wheel Spotting Dish: Position wheel spotting dish

as illustrated in Fig. 1a or 1b. Drill (2) 3/8" holes 2-1/2"

deep in concrete floor using holes in wheel spotting dish

as guide. Drive both anchors, provided, into concrete to

secure dish.

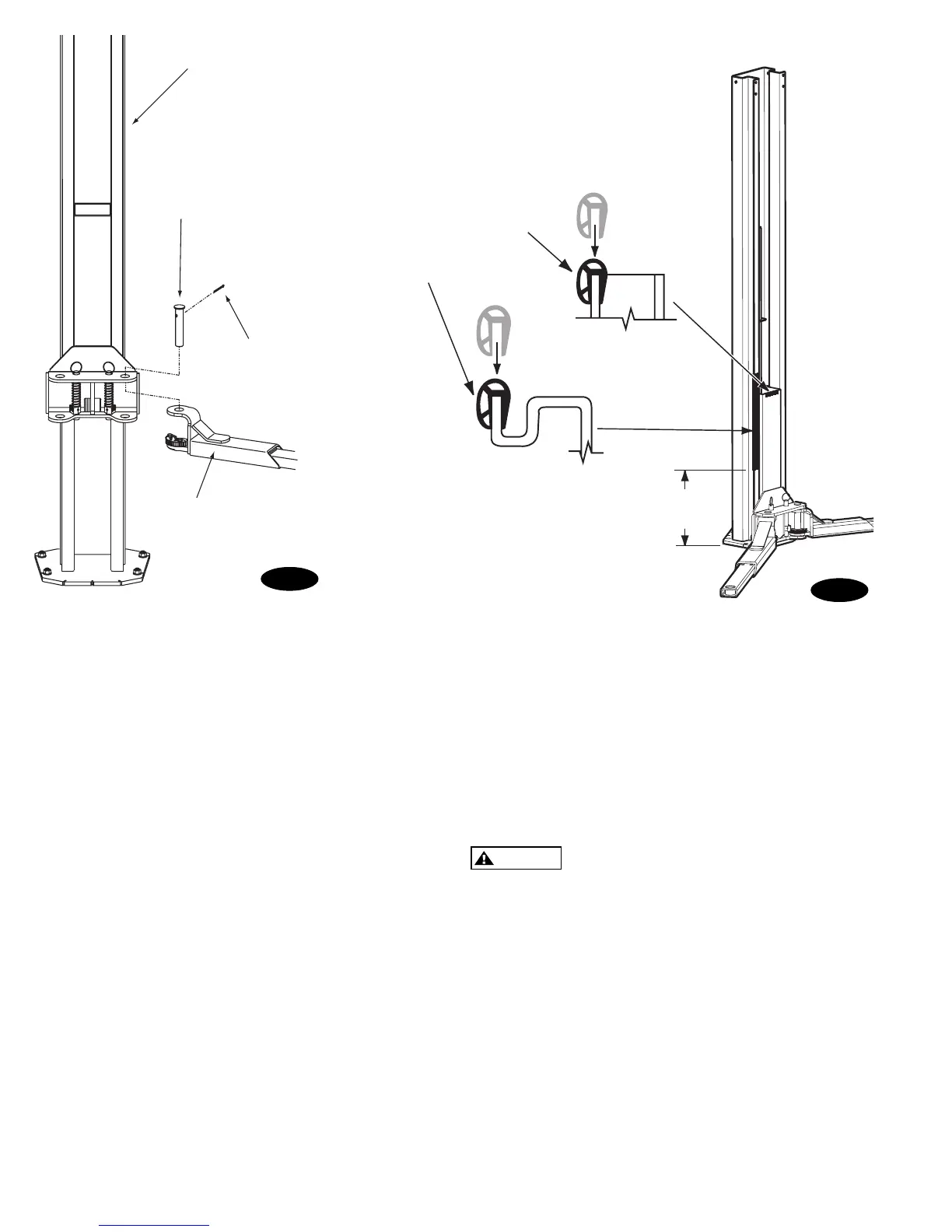

16. Arm Restraints & Superstructure: Before

installing arms, install arm Restraint Gears as follows:

Install Restraint Gear into arm clevis, as shown in Fig. 17,

so that the rounded edge (top side) of the gear teeth is

facing upward. Then, install the (2) 3/8"-16NC x 1-1/2"

HHCS (8 total for all 4 arms) and 3/8" Spring

Lockwashers into the gear and arm as illustrated Fig. 17,

but do not tighten.

After installing Restraint Gears, raise carriages to a

convenient height. Grease swivel arm pins and holes with

Lithium grease. Raise Gear Block by pulling upward on

pin-ring to allow enough clearance for the Restraint Gear

and arm to slide into the yoke clevis and under the teeth

of the Gear Block, Fig. 18. Install 1-1/2" diameter arm

pin(s) and 3/16" x 2" cotter pin(s), Fig. 19. After

installing arm pin, torque the two Restraint Gear bolts to

30-34 ft.-lbs. Let the Gear Block down allowing the teeth

of the Restraint Gear and Gear Block to mesh together,

Fig. 18.

17. Oil Filling & Bleeding: Use Dexron III ATF, or

Hydraulic Fluid that meets ISO 32 specifications.

Column

Arm Pin

Cotter Pin

Arm

Long Bumper

Short

Bumper

Padded section

of door bumper

faces out.

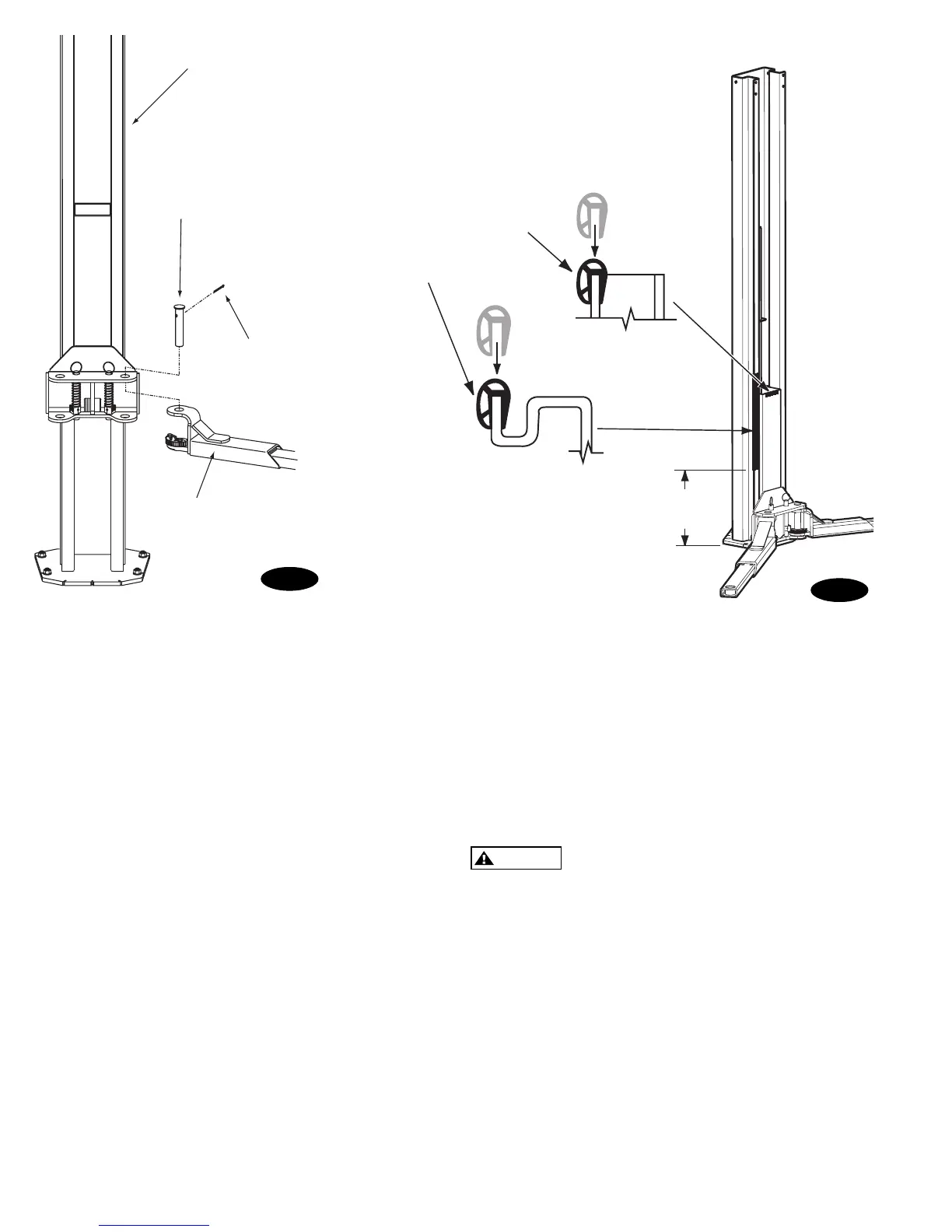

21"

(533mm)

Fig. 19

Fig. 20

Remove fill-breather cap (and fill vent screw for Fenner

Power Unit), Fig. 7a or Fig. 8a. Pour in (8) quarts of

fluid. Start unit, raise lift about 2 ft. Open cylinder

bleeders approx. 2 turns, Fig. 9b.

Close bleeders when fluid streams. Fully lower lift. For

Fenner Power unit, add more fluid until it comes out fill

vent hole. All others fill until it reaches the MIN______

mark on the tank. System capacity is (13) quarts. Replace

fill-breather (and fill vent screw for Fenner Power Unit).

CAUTION

If fill-breather cap is lost or broken, order

replacement. Reservoir must be vented.

18. Door Bumper Installation:

A) Press long bumper on column edge, Fig. 20.

B) Press short bumper on top edge of carriage tube, Fig.

20.

19. Latch Cable Adjustment:

A) Check to make sure the latch will properly engage

and disengage. Slowly release the latch handle. A 1/8

gap between the top of the latch dog and the column

is allowable.

B) When raising, listen to latches to be sure that both

latch dogs fall into latch slots. If they do not, loosen

clamp and adjust tension as necessary.

C) Install left latch cover using 5/16-18NC x 3/8 lg

PHMS.

Loading...

Loading...