7

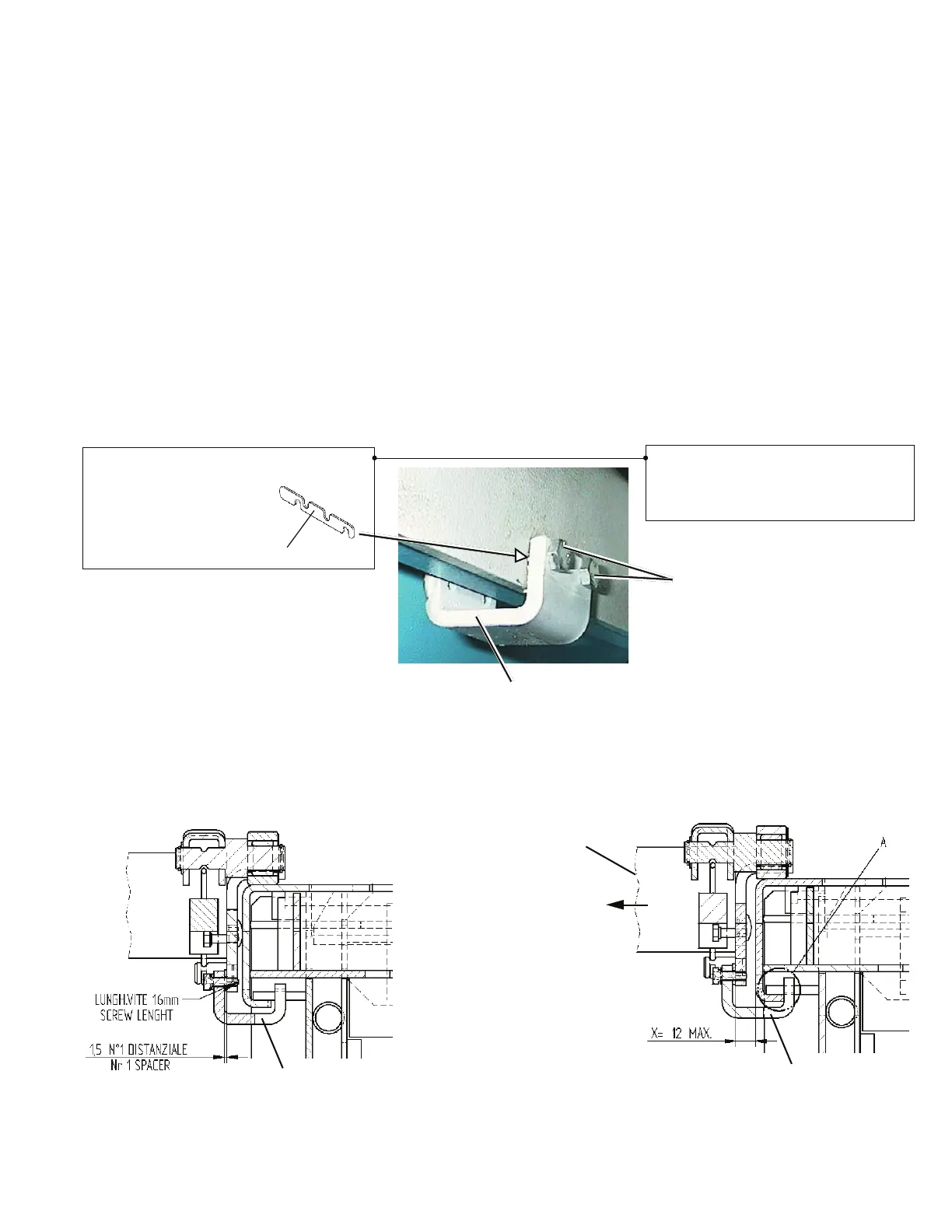

Fig. 6

600-6350 Series lifts 4-Post lifts “without lift

table” nr. 1 spacer

A

1

600-6350 Series lifts 4-Post lifts “without

lift table” nr. 2 screws (Length = 16mm /

0.63”)

B

0.06”

WHEEL-FREE JACK IN “WORKING POSITION”

0.63”

1

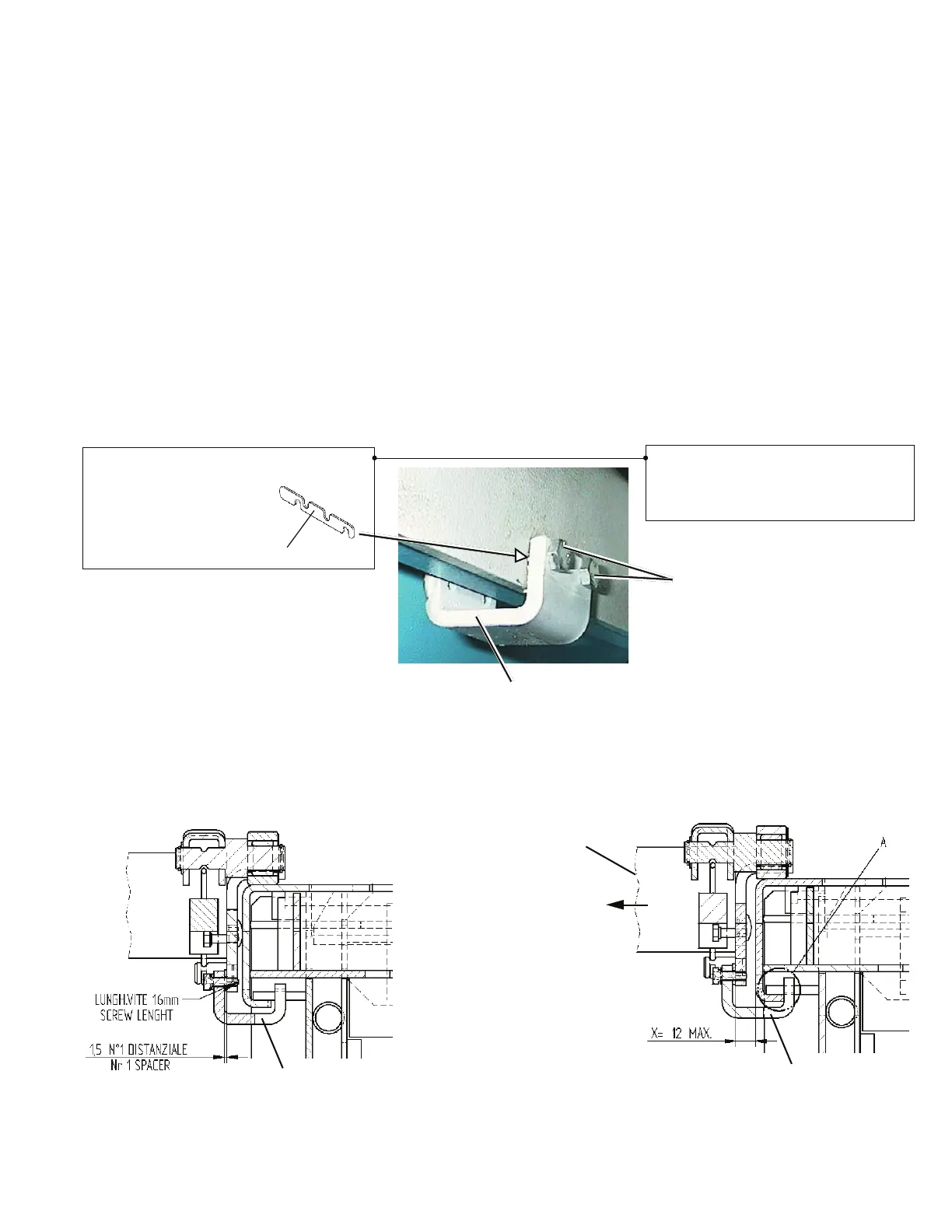

Fig. 7

WHEEL-FREE JACK IN “CHECK POSITION”

2

600 Series lifts

(with platform edge

H=70 mm-2.75”)

600 Series lifts

6350 Series lifts

(with platform edge

H=38 mm-1.5”)

4-Post lifts

(without lift table)

2

2

0.47”

1

1

0.75”

2

4-Post lifts (with lift

table)

0.39”

1

1 1

Fig. 8

Holder brackets adjustment

a) Complete holder brackets 1 Fig. 6 assembly inserting

shims.

A. Tighten screws B.

(Refer to Fig. 6 and 7) Interpose n°1 shims A, with the

screws B of suitable length (16mm-0.63”). Screws

shall not protrude out wheel-free jack bracket, so as

not to damage platforms side surface.

b) Repeat the procedure also on the opposite side.

c) Ref. Fig. 7. Slide wheel-free jack along the whole

platform, making sure it moves properly. Holder

bracket 1 does not have to interfere with platform

edge.

Ref. Fig. 8. While wheel-free jack is sliding onto plat-

form, check X value in different positions.

To carry out this check, move both wheel-free jacks

sliding members 2 away from platforms, with holder

brackets 1 resting onto platforms inner edges (see

area A).

If value X is higher than the specified one, move slid-

ing members in working position, and add one more

spacer. Then, re-check X value.

Loading...

Loading...