9

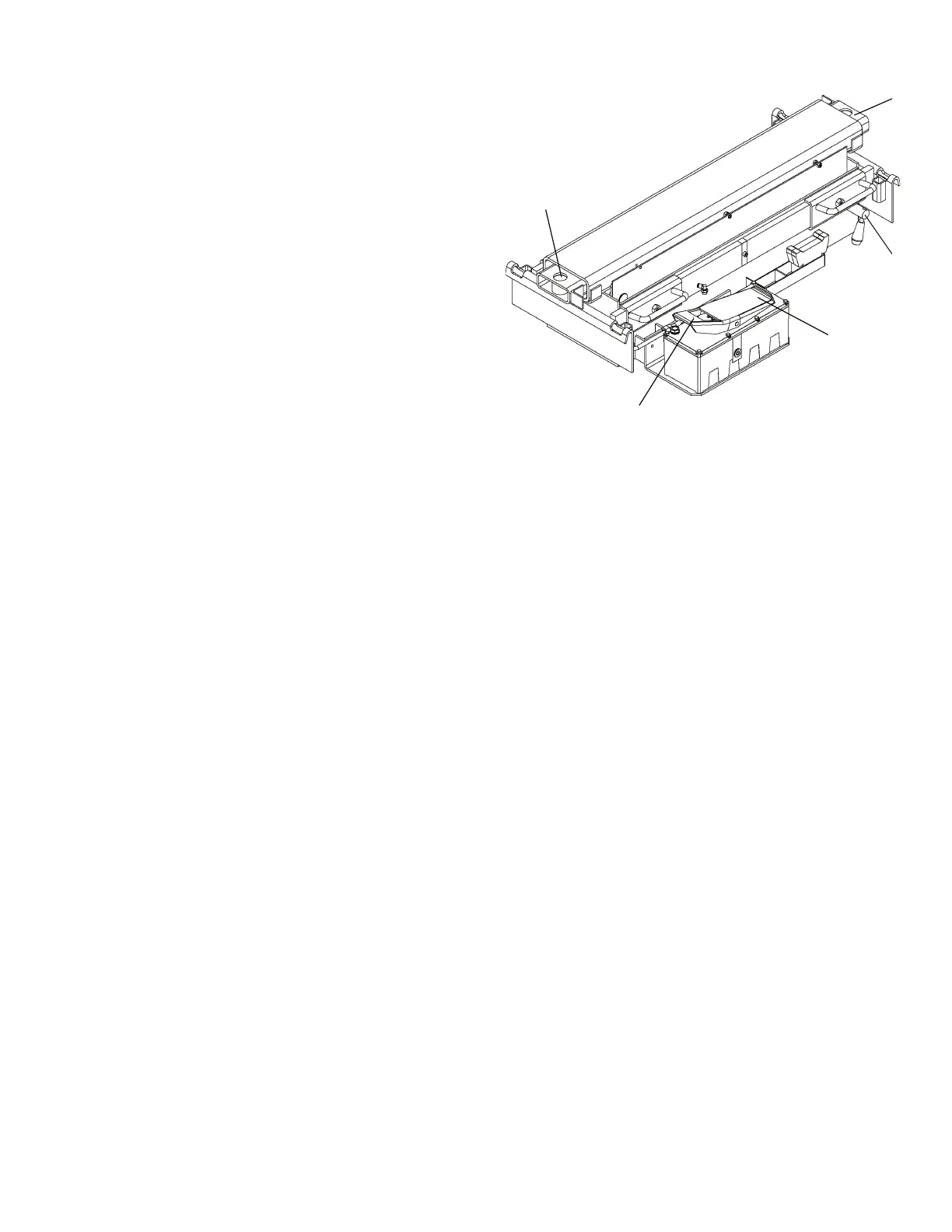

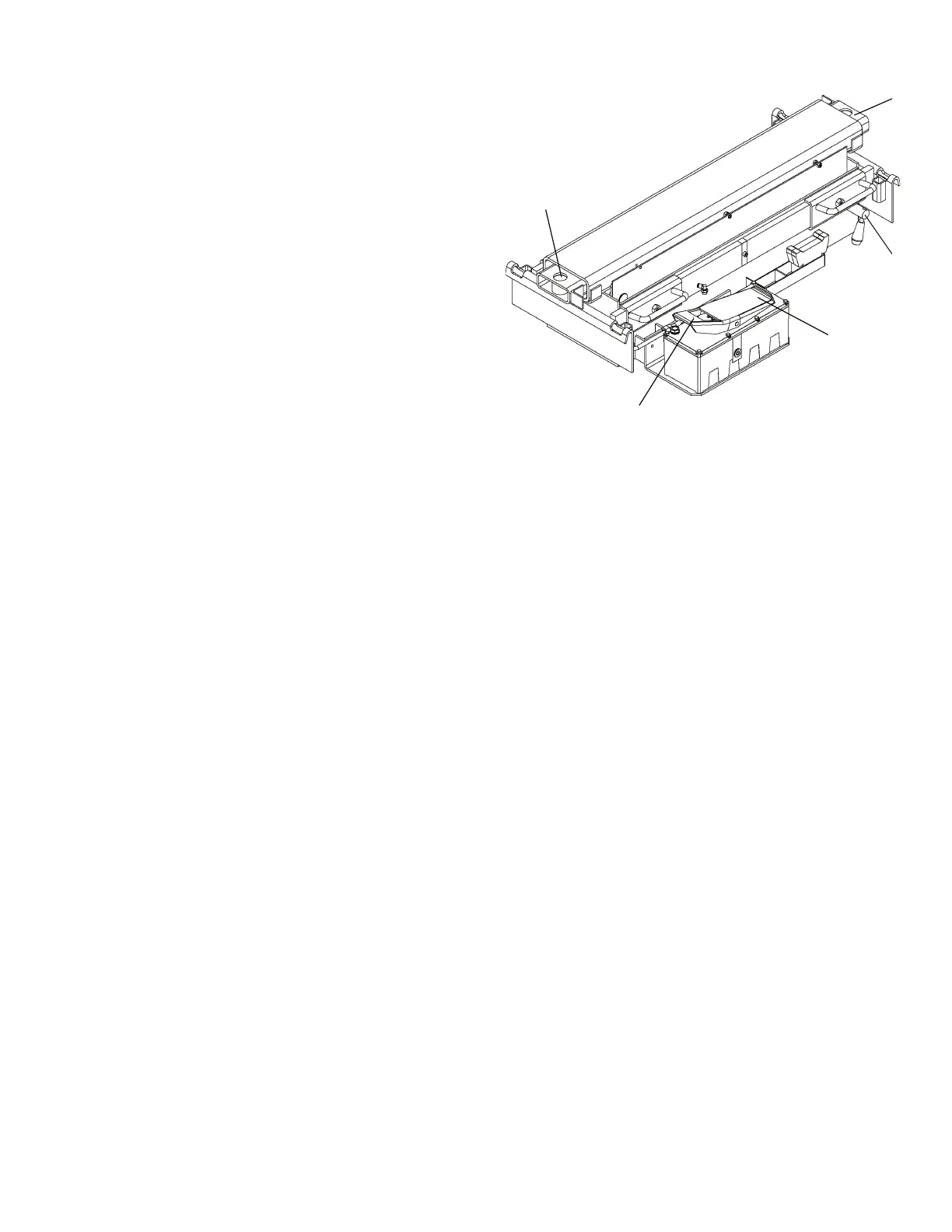

4.2 Description of controls

Always fit the mechanical safety pin (3 Fig. 9) when

operating on vehicles. Make sure supports are prop-

erly positioned under the lifting point.

-Always position the vehicle in the center and use the

parking brake to fully lock it.

Note: Position the load considering that the footboard

and the crosspiece lower.

-Frame should be centerd with respect to the cross-

piece support extension and to buffer supports.

Up:

- Position the jack under the pick-up points.

- Pull out arms 1 and 2 (Fig. 9).

- Position the buffers at the lifting points on arms 1 and

2.

- Press the pump pedal on the “PUMP” side to raise

the wheel free jack.

Down:

- Complete a short elevation stroke by means of the

pump pedal, “PUMP” side.

- Pull out the mechanical safety pin 3.

- Press the pump pedal on the “RELEASE” side;

- Pull back the support arms 1 and 2.

5. DESCRIPTION AND FUNCTION OF THE SAFETY

COMPONENTS

5.1 Warning

The safety components described in this section

provide proper and safe operation of the machine. The

manufacturer recommends regular checks of efficien-

cy, cleaning and adjustment (where possible).

Any unauthorized modifications or tampering with the

equipment release the manufacturer from any liability

for damages caused by or related to the above men-

tioned acts. Removal of or tampering with safety de-

vices constitutes an infringement of European Safety

Regulations.

5.2 Mechanical stop device

- The crosspiece is fitted with a threaded ring nut to

block accidental descent of the load due to breakage

in the oleodynamic system.

5.3 Device for overload protection

- The lift is fitted with a calibration valve to prevent lift-

ing of vehicles exceeding the set capacity.

Fig. 9RELEASE

PUMP

1

2

3

6. USING THE SUPPLIED ACCESSORIES

- To help the operator, the jack can be used with sup-

plied accessories. Only original accessories from the

manufacturer should be used.

7. MAINTENANCE

- The machine and the working area must be cleaned

but compressed air should never be used for clean-

ing.

- Painted surfaces should be cleaned.

- Moving parts must be cleaned and well-lubricated.

- Should the crosspiece be left unused for a long time,

the gaskets should be checked (to make sure that

they are not damaged), as well as the circuit and the

lubrication of any moving parts.

7.1 Changing the oil

The oil should be changed at least every 100 working

hours, using MOBIL DTE 11 oil or ESSO INVAROL ET 22

or the equivalent.

Check the level regularly. The minimum level is 15 mm-

0.6” from the edge of the top-up plug.

7.2 Cleaning the valve and filter

Cleaning should be done using petrol and compressed

air. Pay special attention when fitting and removing the

valve and filter. Regularly clean the air filter (replacing

if necessary) located inside the compressed air infeed

coupling.

Loading...

Loading...