d06322.fm

SI-912 i-001R4

SI-912-016R9 / SI-914-019R9

SERVICE INSTRUCTION

27 March 2017 12-10-00

page 5 of 11

Copyright - BRP-Rotax GmbH & CO KG. All rights reserved.

4) Coolant

4.1) General

All engine types 912 i, 912 and 914 Series have liquid cooled cylinder heads and ram air cooled

cylinders. The function of the coolant is to protect the cylinder heads from over-temperature by

means of heat dissipation. Protection against corrosion of the engine components and freezing of

the coolant is achieved with appropriate additives.

In principle, 2 different types of coolant are permitted:

- Conventional coolant based on ethylene glycol with 50% water content

- Waterless coolant based on propylene glycol (not allowed for 912 i Series)

4.2) Conventional coolant

Conventional coolant (with about 50% water content) has a specific thermal capacity that is higher

than waterless coolant. It gives excellent corrosion protection, especially for aluminum, and pro-

tection against freezing.

NOTE: For exact monitoring of the coolant temperature, a limit has been set. This

is necessary because standard coolant based on ethylene glycol such as

BASF Glysantin in a 50/50 proportion mixture can boil at a temperature as

low as 120 °C (248 °F). Refer to the current Installation Manual for more

information and instructions.

NOTE: Coolant should be a low silicate and nitrite free formula. Follow coolant

manufacturer directions regarding mixture percentages etc..

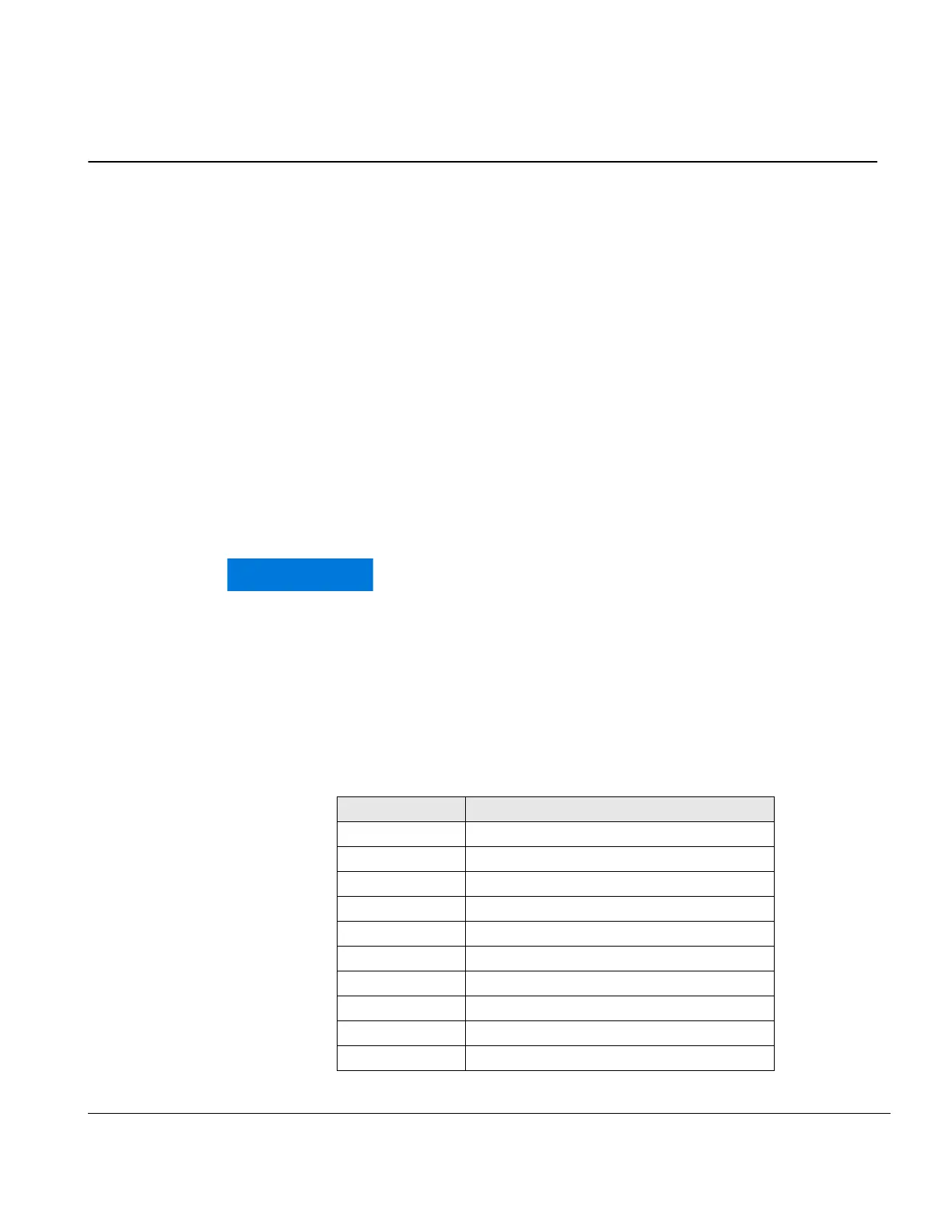

Coolants with a mixture of 50% antifreeze and 50% of distilled water recommended by the

authorized distributors (not tested from BRP-Rotax).

NOTE: The following list is based on the experiences and local recommendation

by the authorized distributors. Coolant brands, with same designation, may

vary from one to the other region. Please contact the local distributor for a

recommendation.

The certification and determination of the correct coolant type must be

conducted by the aircraft manufacturer. As each aircraft type has different

characteristics, testing must be done to determine the most suitable cool-

ant and instrumentation for each aircraft type.

Brand Description

BASF

®

Glysantin Protect Plus/G48

CASTROL

®

Antifreeze All-Climate

CASTROL

®

Antifreeze Anti-Boil

OMV

®

OMV Coolant Plus

PETROL

®

Antifreeze Concentrate / Antifreeze G 11

PRESTONE

®

DEX-COOL extended life

PRESTONE

®

50/50 preluded DEX-COOL extended life

SHELL

®

DEX-COOL

SHELL

®

Antifreeze Concentrate

TEXACO

®

Havoline Extended Life Antifreeze

Loading...

Loading...