5 x Glossary

BA ROTEX HPSU compact 4 - 03/2013

31

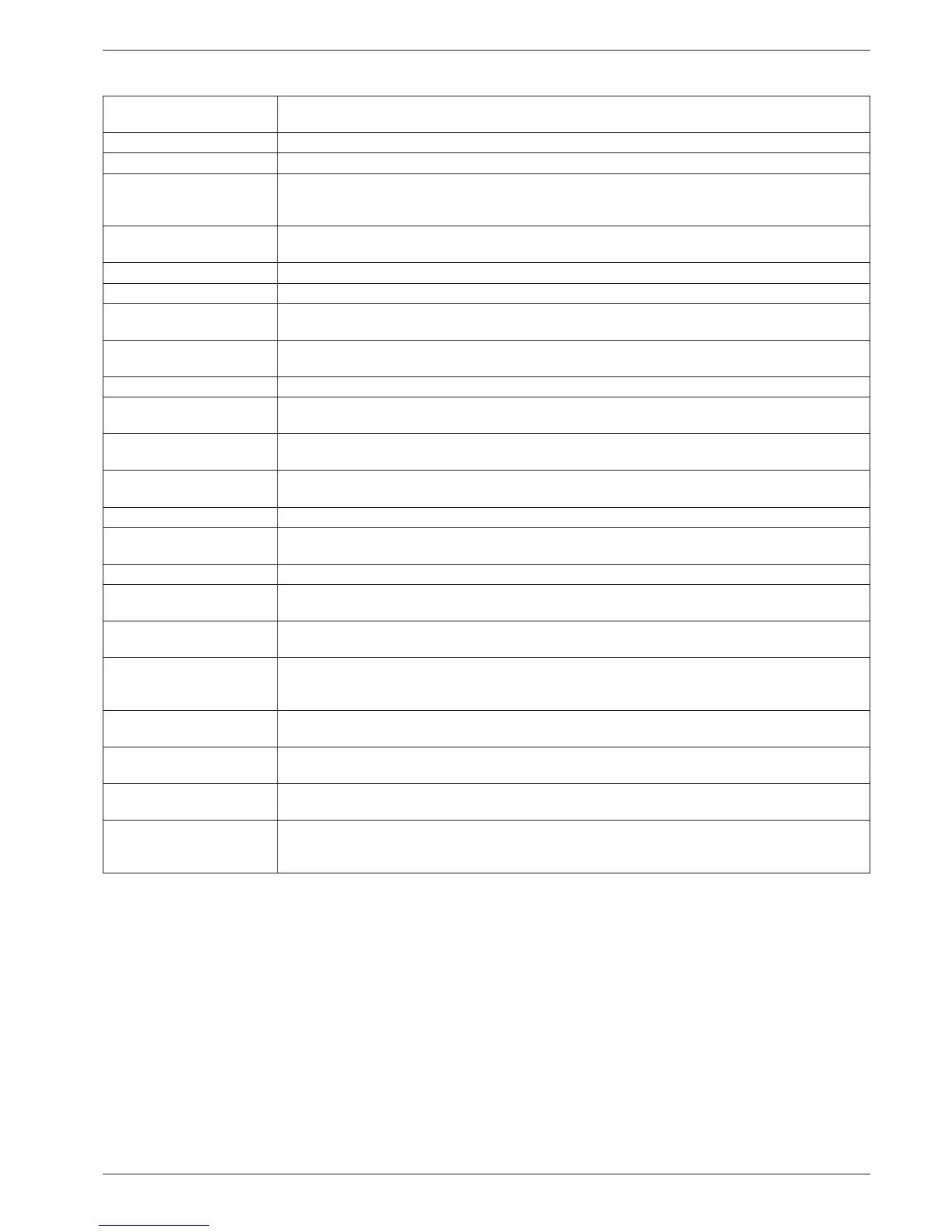

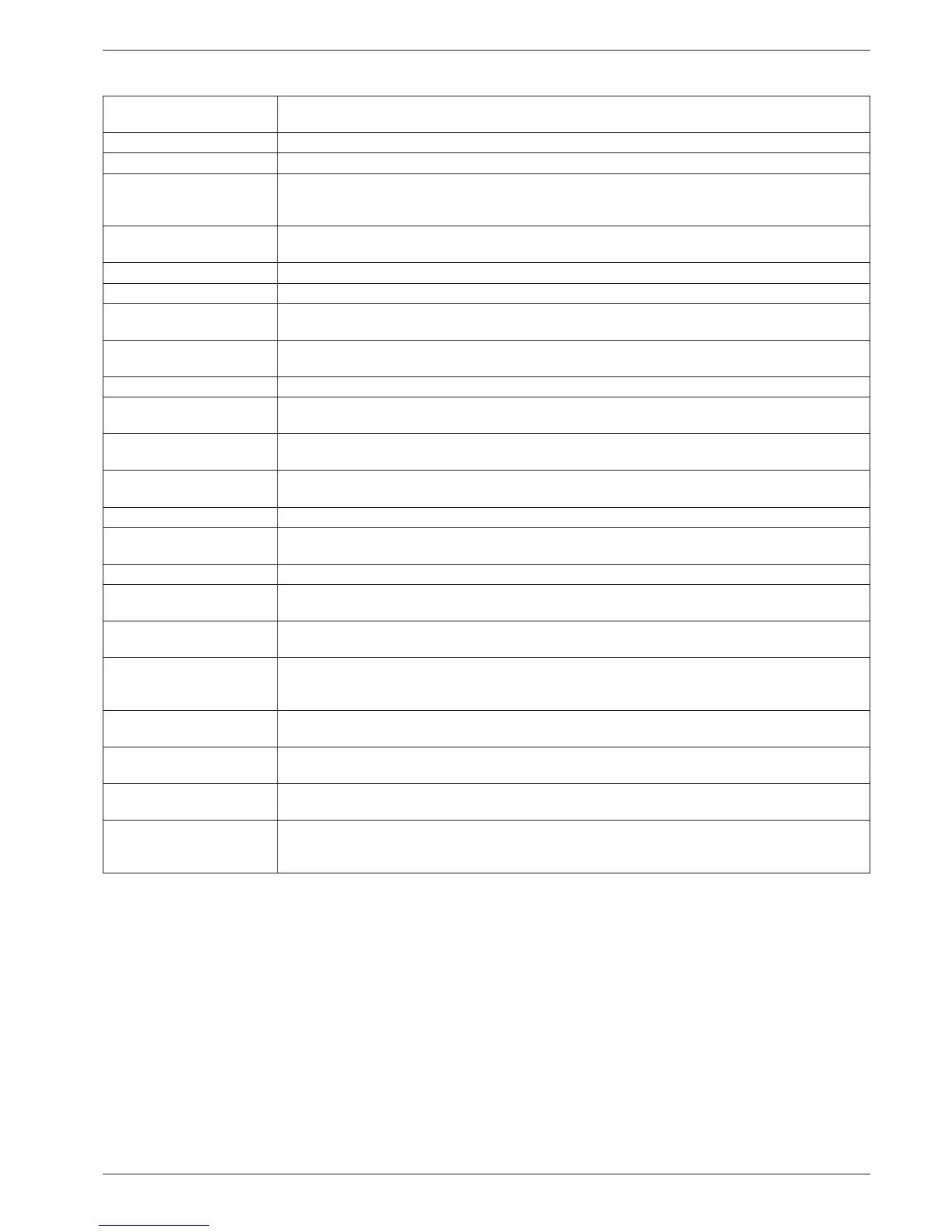

5 Glossary

Anti-legionella system Periodic heating of storage water to > 71 °C for preventative elimination of pathogenic bacteria in the

hot water circuit (so-called legionella).

Backup function Operation for support of the HPSU compact during heat generation (by backup heater)

Backup heater Optional electric ancillary heater for general support of the HPSU compact during heat generation.

Circulation circuit Is an optional ancillary circuit in the hot water circuit which serves to ensure that hot water flows out of

the discharge point as soon as the tap is turned on. In this circuit the hot water circulates via a circu-

lation pump between the hot water storage tank and the draw-off point.

Control Operating unit in front area of the heat generator that houses the programme selection buttons, rotary

switches and the display.

Direct circuit Is the water circuit which is heated in an uncontrolled manner directly by the heat source.

Flow Part of the hydraulic circuit which directs the heated water from heat generator to the heating surfaces.

Heat exchanger A part that transfers thermal energy from one circuit to another. Both circuits are separated from each

other hydraulically by a wall in the heat exchanger.

Heating characteristic curve Mathematical relationship between the external temperature and the target flow temperature (synonym

= heating curve), in order to achieve the desired room temperature at all outside temperatures.

Hot water circuit Is the water circuit in which the cold water is heated and directed to the hot water discharge point.

Low tariff mains connection

(HT/NT)

A special mains connection to the energy supplier, which offers various cheaper rates during so-called

low-load periods for electrical current (day-, night-, heat pump current, etc.).

Mixing circuit Is a water circuit that flows through various different heating circuits (as required) in a controlled

manner.

Modulation Automatic and continuous adjustment of the heat output to the heat requirement at the time, without

having to switch various heat stages or cycles.

Nominal output Maximum heat output, which the heat generator emits at certain operating temperatures.

Operating mode Function of the heat exchanger requested by the user or control unit (e.g. room heating, hot water

heating, room cooling, standby etc.)

Parameter A value that influences the execution of programs or processes or defines specific states.

Refrigerant A material which is used for thermal transfer in a coolant system. At low temperature and low pressure,

heat is absorbed and at high temperature and a high pressure, heat is emitted.

Return flow Part of the hydraulic circuit that directs the cooled water from the radiators in the rooms back to the

heat generator via the piping system.

SMART GRID (SG) Intelligent energy utilisation for economical heating. Using a special electricity meter it is possible to

receive a "Smart Grid Signal" from the energy supply company which, depending on the signal, moves

the heat generator into the standby, normal or storage tank operating mode.

Storage tank charging circuit Is the water circuit which heats the water stored in the hot water storage tank (not to be confused with

the hot water circuit).

Switching time programme Programme for setting the times on the controller in order to specify the regular heating, setback and

hot water phases.

Water shortage/ overheating

protection

Safety device which switches the boiler off automatically in the event of a water shortage to prevent

overheating.

Weather-dependent set

value regulation

The suitable flow temperature is calculated from the measured value for the external temperature and

a defined heating curve; this temperature serves as the target value for temperature control in the

heating unit.

Loading...

Loading...