TECHNICAL MANUAL FOR THE RDR BL3 - V1.1 DRIVE ROLLER Rev. 21/09/2018 page 13

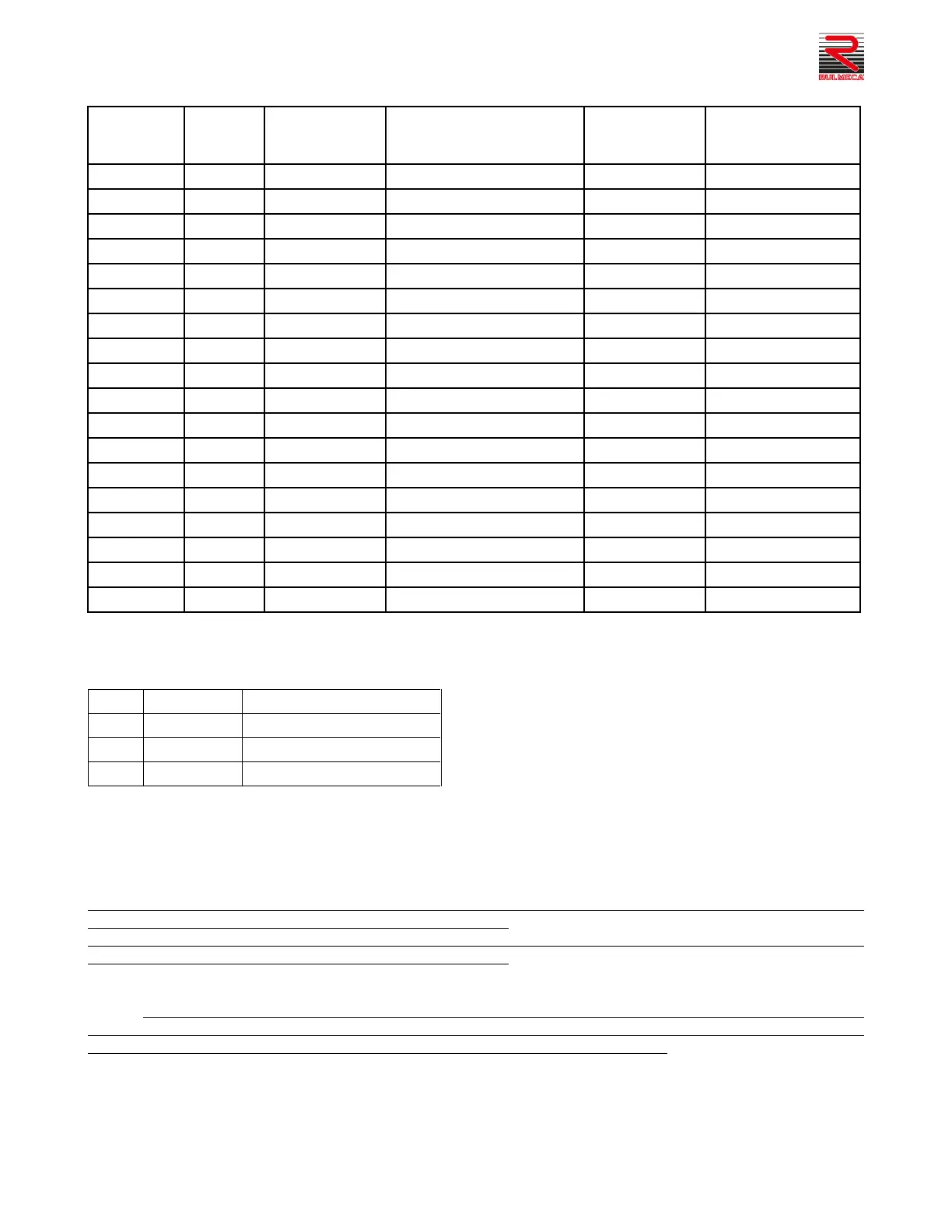

POSSIBLE POLY-V BELTS AND ROLLER PITCHES

Reference printed

on belt

Roller pitch (pulley

Ø43) [mm]

Actual extent of belt at

rest [mm]

Poly-V belt, 2 or 3 ribs, PJ 256

Poly-V belt, 2 or 3 ribs, PJ 270

Poly-V belt, 2 or 3 ribs, PJ 282

Poly-V belt, 2 or 3 ribs, PJ 286

Poly-V belt, 2 or 3 ribs, PJ 288

Poly-V belt, 2 or 3 ribs, PJ 290

Poly-V belt, 2 or 3 ribs, PJ 314

Poly-V belt, 2 or 3 ribs, PJ 316

Poly-V belt, 2 or 3 ribs, PJ 336

Poly-V belt, 2 or 3 ribs, PJ 346

Poly-V belt, 2 or 3 ribs, PJ 356

Poly-V belt, 2 or 3 ribs, PJ 376

Poly-V belt, 2 or 3 ribs, PJ 388

Poly-V belt, 2 or 3 ribs, PJ 416

Poly-V belt, 2 or 3 ribs, PJ 442

Poly-V belt, 2 or 3 ribs, PJ 456

Poly-V belt, 2 or 3 ribs, PJ 486

Poly-V belt, 2 or 3 ribs, PJ 536

Warning the order code does not give the roller pitch. For permitted roller pitches, see the relevant column.

Warning the printed reference number on the belt (PJ-XXX) is not the extent and must not be used to calculate roller pitch.

The original winding diameter of the belt is calculated as 1 mm above the pulley: Dp = Ø pulley + 2 mm.

Recommended average tension 5%. Min/max permitted tension range 4-6%.

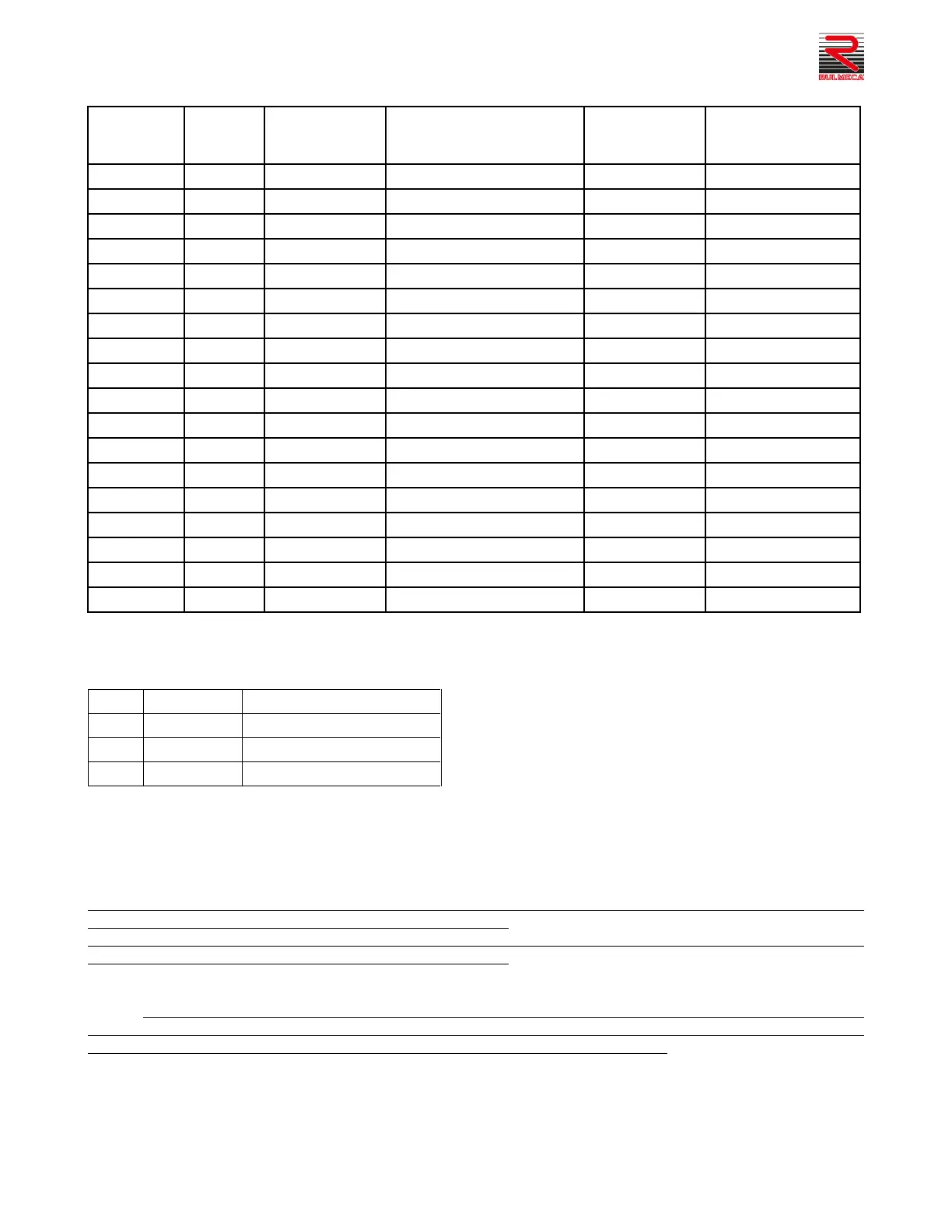

Torque transmitted by Poly-V belts with 4% min. pretensioning

Torque loss per transmission ring

Recommendations on fitting Drive Rollers

In roller conveyors provided with transmission systems with round straps or Poly-V belts, it is fundamental to install

the Drive Roller in a position that is central to the conveying area, with a similar number of driven rollers upstream

and downstream of the Drive Roller. If there is a precision stop or a significant package load, the Drive Roller can

be positioned as the first or second roller of the area, provided that the driven rollers on the other side are limited.

Technologically, the two different transmission systems ensure different performance with use restrictions.

If round straps are used, do not exceed the maximum number of 10 driven rollers connected to each Drive

Roller, and position the Drive Roller in the middle of the area.

If Poly-V belts are used, do not exceed the maximum number of 20 driven rollers connected to each Drive

Roller, and position the Drive Roller in the middle of the area.

The above quantities are maximum quantities for ensuring efficient transmission. If the above quantities are

exceeded, the decline in general performance may be considerable and may not ensure sufficient conveying

torque. These maximum numbers of driven rollers could be decreased, depending on the torque that can be

supplied by the different Drive Roller ratio reductions, depending on the loads to be conveyed and calculating the

torque required on the basis of the data specified above and the type of belt chosen.

Loading...

Loading...