SETUP 4

3

1

2

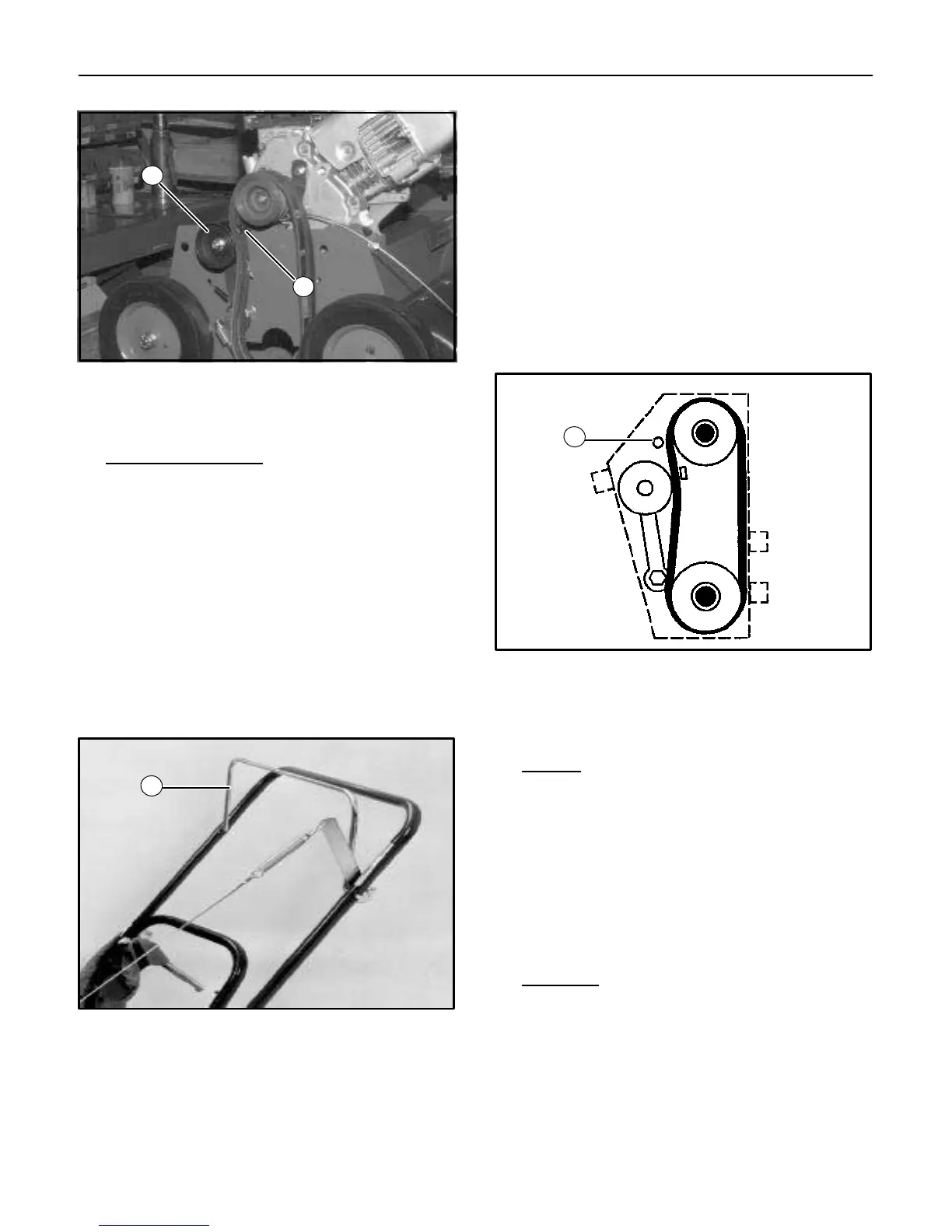

FIGURE 4

1. Snubber

2. Idler Pulley

4.4 HANDLE AND CABLE

INSTALLATION

1. Assemble the upper and lower handle sections using

the hardware provided in the loose parts bag.

2. Mount the handle to the unit by placing the bottom

ends of the handle over the pins at the top edge

center of the chassis. Secure the handle with

hairpins (from loose parts bag).

3. Connect one end of the spring (from loose parts bag)

to the clutch cable and the other end to the arm of the

clutch bail on the handle. See Figure 5.

1

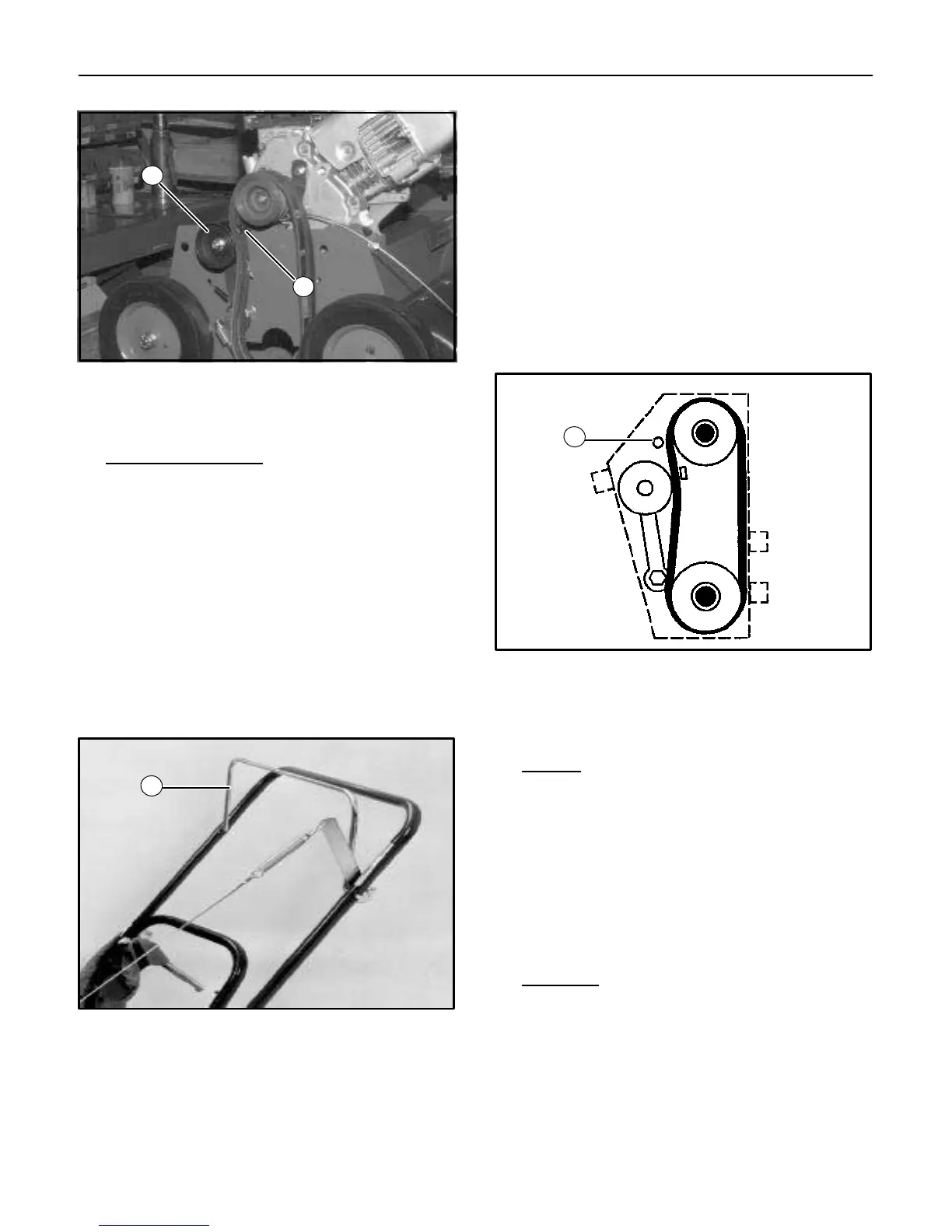

FIGURE 5

1. Clutch Control Bail

4. Pull the bail back against the handle. The idler pulley

should be tight against the reel belts when the bail is

against the handle.

5. Release the bail. The idler pulley should move away

from the reel belts and allow the belts to slip on the

engine pulley when the bail is released.

6. Reinstall the belt guards. The belt stop rod should be

positioned outside the belts, as shown in Figure 6.

1

FIGURE 6

1. Belt Stop Rod

4.5 WHEEL BEARING LUBRICATION

Using a pressurized lubrication gun and a lithium based

lubricant, lubricate the wheel bearings. This procedure

should be done at the time of setup and also after every

25 hours of service.

NOTE:

During setup, each wheel cavity should be filled.

The cavity is full when lubricant is seen coming out

of bearing.

4.6 BLADE HEIGHT ADJUSTMENT

Blade height is adjusted by loosening the locking lever

and turning the adjusting knob to raise or lower the front

wheels. See Figure 7.

Loading...

Loading...