52 Technical Description

Boost pressure control

3

l

I

2/

/'

,,,5

-i

6

c,,,

j7

◊~

µp

bask¢

1

I

3

I

5

I

I

2 4

I

R

µp

◊

1~1

2

l~I

26

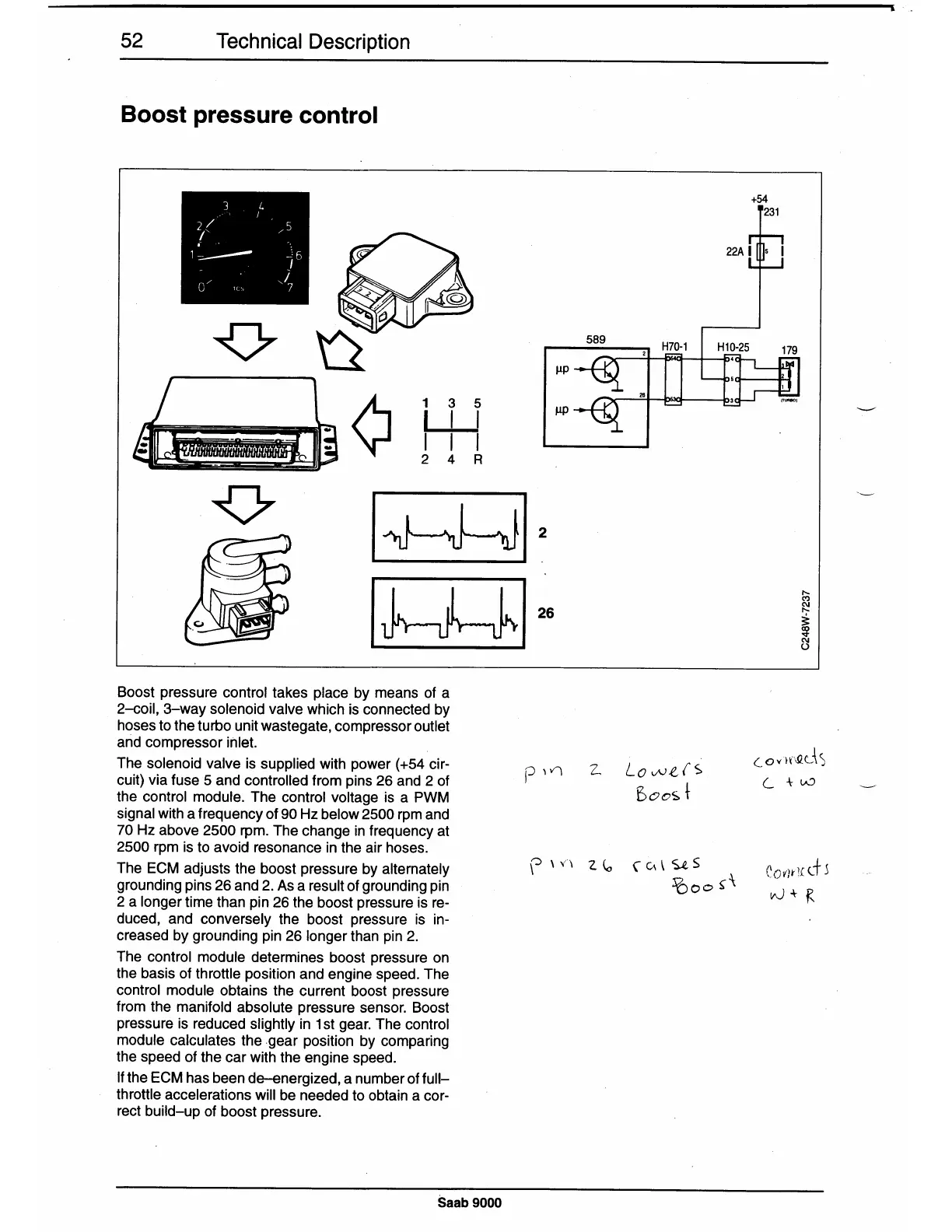

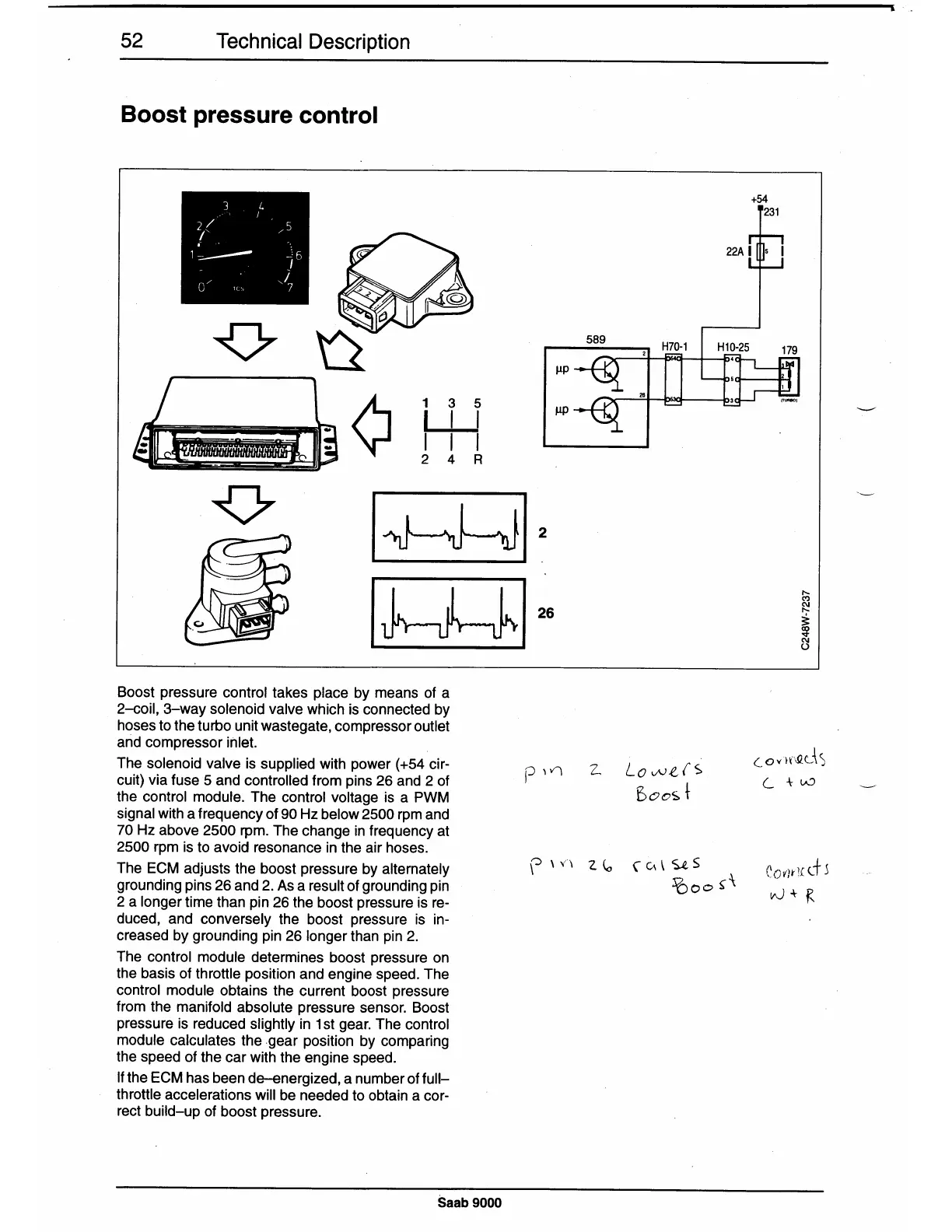

Boost pressure control takes place by means of a

2-coil, 3-way solenoid valve which is connected by

hoses to the turbo unit wastegate, compressor outlet

and compressor inlet.

The solenoid valve is supplied with power (+54 cir-

cuit) via fuse 5 and controlled from pins 26 and 2 of

the control module. The control voltage is a PWM

signal with a frequency of 90 Hz below 2500 rpm and

70 Hz above 2500 rpm. The change in frequency at

2500 rpm is to avoid resonance in the air hoses.

The ECM adjusts the boost pressure by alternately

grounding pins 26 and 2. As a result of grounding pin

2 a longer time than pin 26 the boost pressure is re-

duced, and conversely the boost pressure is in-

creased by grounding pin 26 longer than pin 2.

The control module determines boost pressure on

the basis of throttle position and engine speed. The

control module obtains the current boost pressure

from the manifold absolute pressure sensor. Boost

pressure is reduced slightly in 1st gear. The control

module calculates the .gear position by comparing

the speed of the car with the engine speed.

If the ECM has been de-energized, a number of full-

throttle accelerations will be needed to obtain a cor-

rect build-up of boost pressure.

Saab

9000

p,v1

r

\

Y\

'2.

~

+54

231

22A

I

s

I

(_ov}f&.d<:i

(_ -\- l,v

Co11r1,e<..f

5

vJ

+

R

Loading...

Loading...