Operator’s manual

Front disc mower

KDF 390

- 20 -

6.5.2. After-season maintenance and storing of machine

At the end of the season the mower should be cleaned, washed and dried. Carefully grease

unpainted surfaces and 3-point linkage pins.

After that the following work should be carried out:

remove any traces of rust and paint the area affected,

check lubrication of intersecting axis gear and cutterbar (chapter 7). If leaks occur, remove

them immediately. If water is discovered in the oil, it must be changed, otherwise the gears,

bearings and shafts could be damaged,

periodically inspect the mower and lubricate moving parts in order to protect them from

corrosion which effects proper operation of the mower.

After storage period, before the machine is used:

check the mower's technical condition, and the transmission in particular,

supplement the paint where missing,

make sure that all nuts and screws are tightened properly (Tab. 5),

make sure that all guards are in place,

protect all moving parts with grease in order to prevent their baking and creating any sources of

corrosion, which significantly influences mower's proper operation,

check oil level in axis gears and cutterbar. If leaks are found remove them immediately and

refill the oil. If water in oil is found, immediately change the oil as it could cause corrosion of

internal mechanisms such as gear wheels, bearings, or shafts, and cause breakdowns.

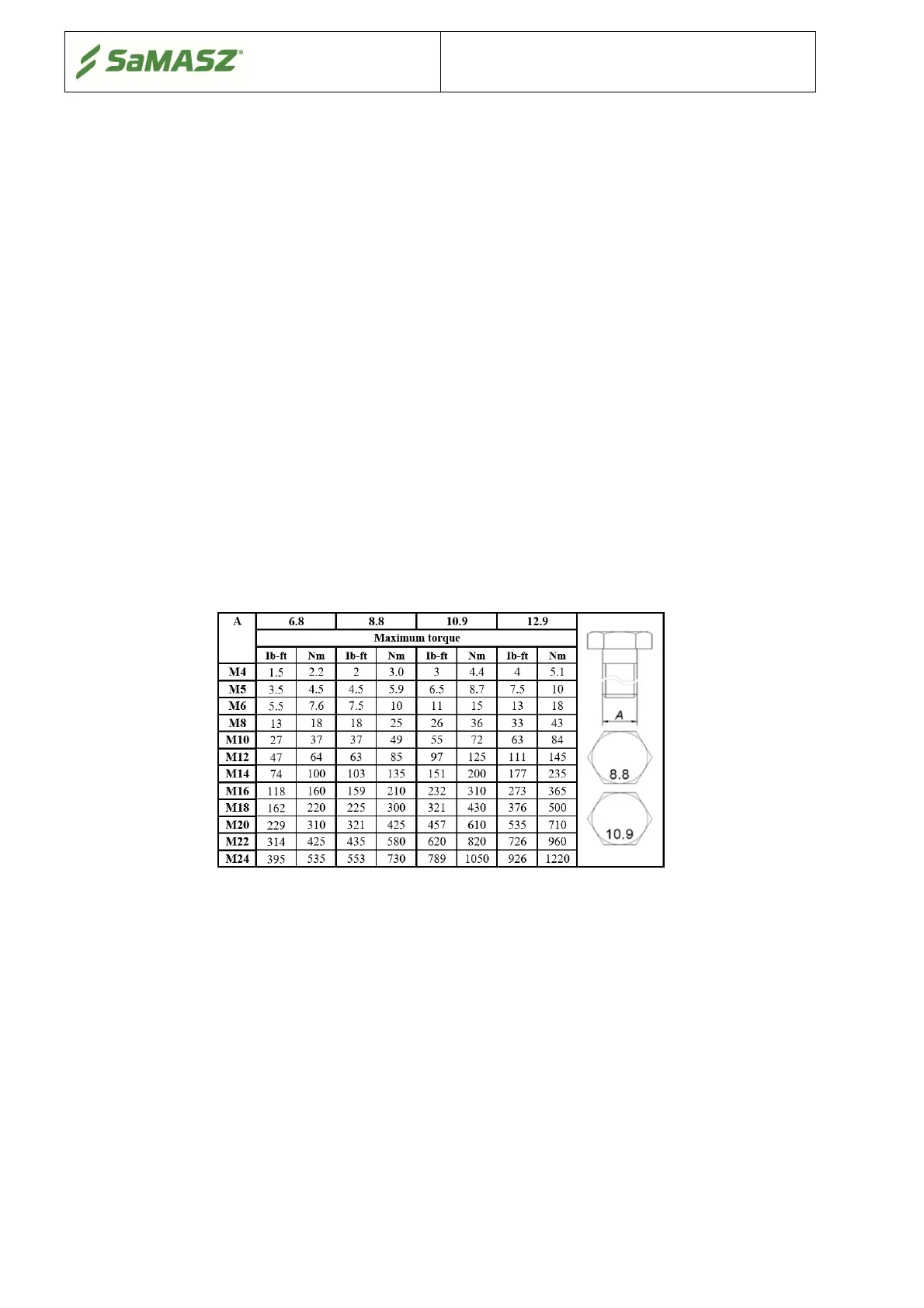

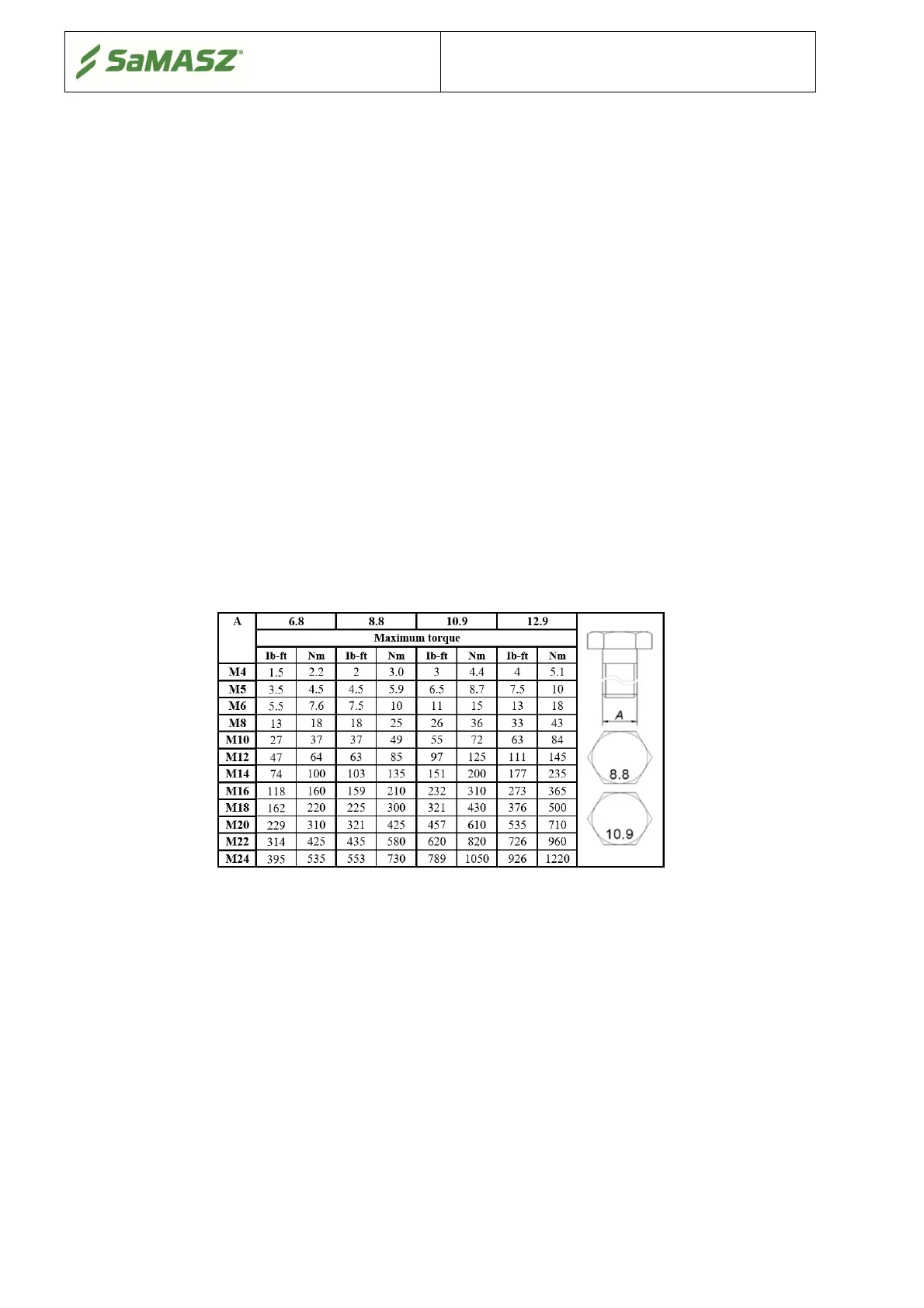

Tab. 5. Torque values for bolts

In the absence of specific torque values, the following chart can be used as a guide to the

maximum safe torque for a particular size and grade of fastener. There is no torque difference for

fine or coarse threads. Torque values are based on clean, dry threads. Reduce value by 10% if

threads are oiled before assembly.

Loading...

Loading...