Operator’s manual

Bale wrapper

Spin

- 14 -

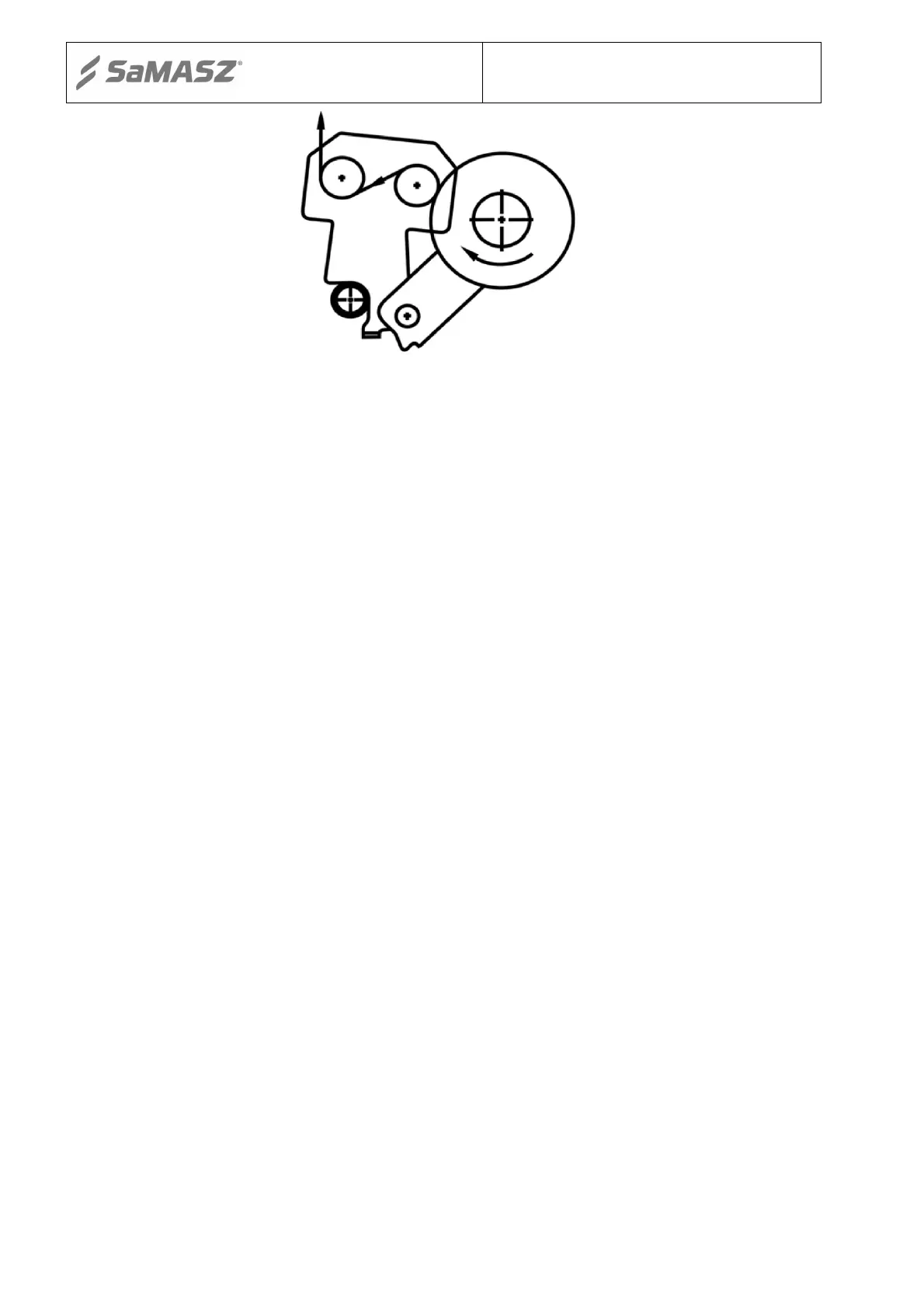

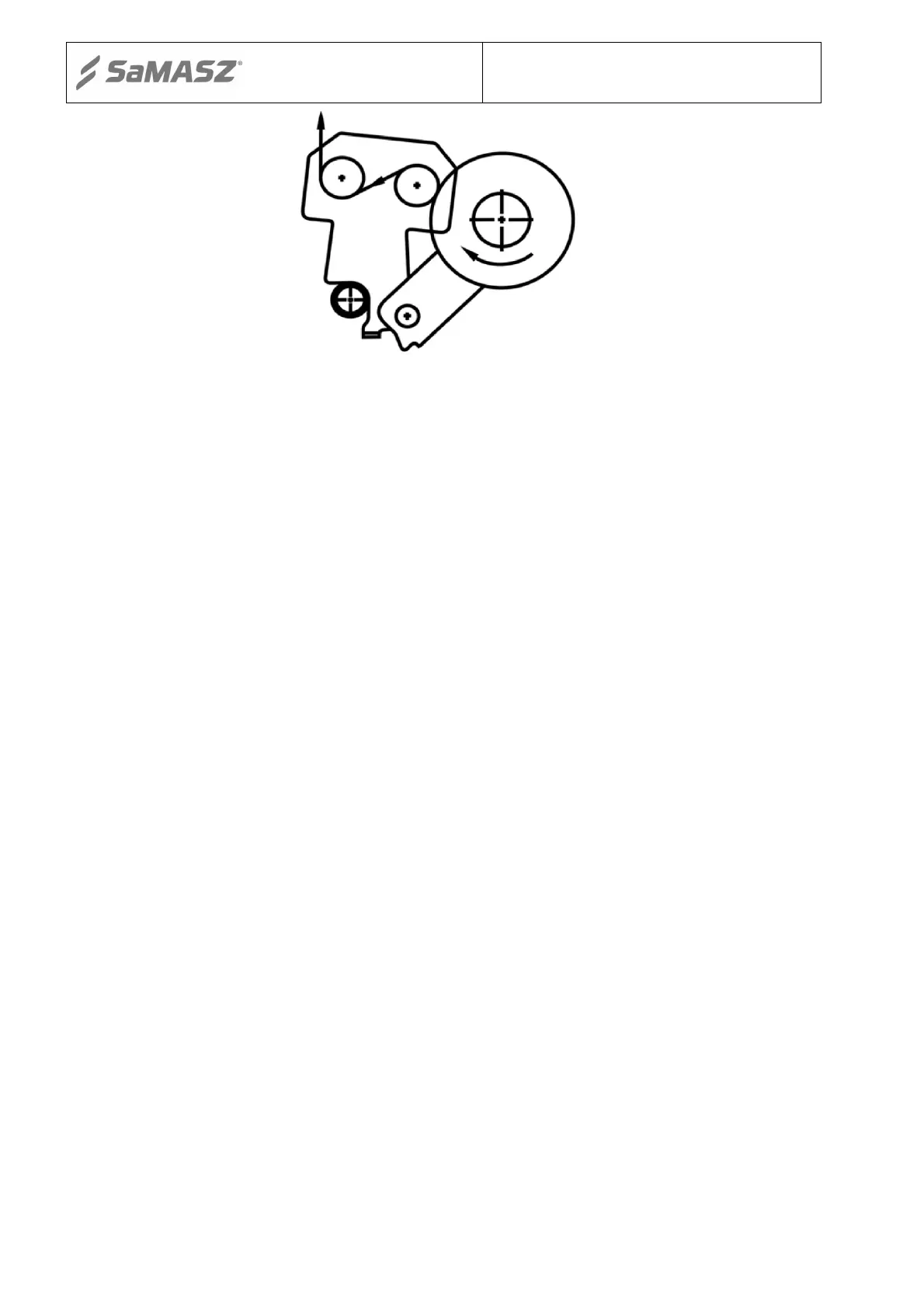

Fig. 8. Film movement diagram

8. WRAPPING MACHINE OPERATION

8.1. Installing the film

Place the film roll on the feeder pin in the following order (see diagram):

Deflect the support with the metal rollers and secure it using the hook attached to the wrapping

assembly.

Using a lever (crank) undo the upper pin pressing the film upwards.

Set the height of the lower pin in position appropriate for the film roll width (1' 8" or 2' 6").

Place the film roll on the lower conic pin.

Clamp the roll by turning the lever (crank) on the upper pin so that the roll is securely held in

the vertical position.

Protect the roll from unscrewing using the nut on the crank screw.

When installing the roll of film, place its internal sticky side towards the bale axis.

Properly set the initial tightening of the film.

Pull the film through the rubber rollers as indicated on the diagram located on the gear cover.

Pull the end of the film so that it may be easily handled in the machine.

The wrapping machine is pre-set to use 1' 8" film. To use 2' 6" film, the chain wheel must be

replaced (Fig. 9). To do so, it is required to:

Unscrew the 2 bolts 6 and remove the cover protecting the main shaft,

Loosen the M12 screw on the chain tightening mechanism,

Remove the chain from the Z11 chain wheel installed on the main shaft,

Remove the Z11 chain wheel form the shaft (using an appropriate tool),

Replace it with a Z16 chain wheel,

Secure the Z16 wheel repeating the above procedure in the reverse order.

Loading...

Loading...