9-26 EB 8052-E EN

Servicing and conversion

15. LLF20 packing: insert packing follower

(8).

Standard and HT packing: screw in

threaded bushing (8).

16. Place yoke (60) on the valve bonnet (2)

and fasten using the castellated nut (92).

17. LLF20 packing:

− Place packing gland (162) over the

studs (164) on the valve body (2) on-

to the packing follower (8).

− Screw the two spring loading assem-

blies (163) onto the studs (164) and

guide them through the holes on the

packing gland.

Standard and HT packing: continue as

described in step18.

18. Adjust the packing (see information un-

der 'Adjusting the packing' in the 'Instal-

lation' section > 'Testing the installed

valve' > 'Leak test').

19. Loosely thread lock nut (10) and stem

connector nut (9) onto the piston stem

(5.1).

Valve version with anti-rotation xture

11. Continue as described in steps 11 to 18

of the previously described procedure

‘Valve version without anti-rotation x-

ture’ on page9-25.

12. Apply a thin lm of lubricant (114) to the

threads of the stem (9) and screws (303).

Impaired functioning due to incorrectly ap-

plied lubricant.

Î Do not apply any lubricant to the threads

of the clamps (301) or the plug stem.

13. Position the clamps (301) and stem (9)

on the piston stem according to the

'Mounting dimensions' table in the 'In-

stallation' section (under 'Mounting the

external anti-rotation xture') and tighten

screws (303) and washers (304) by

hand.

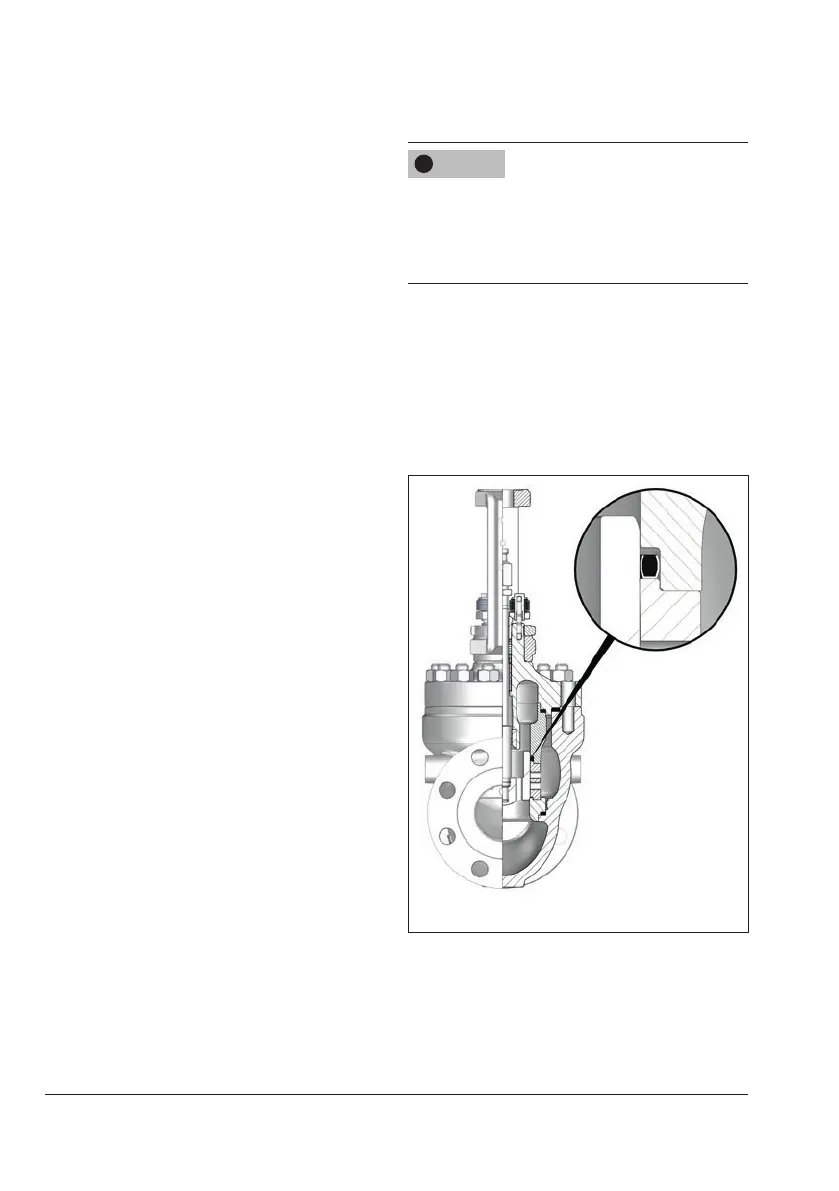

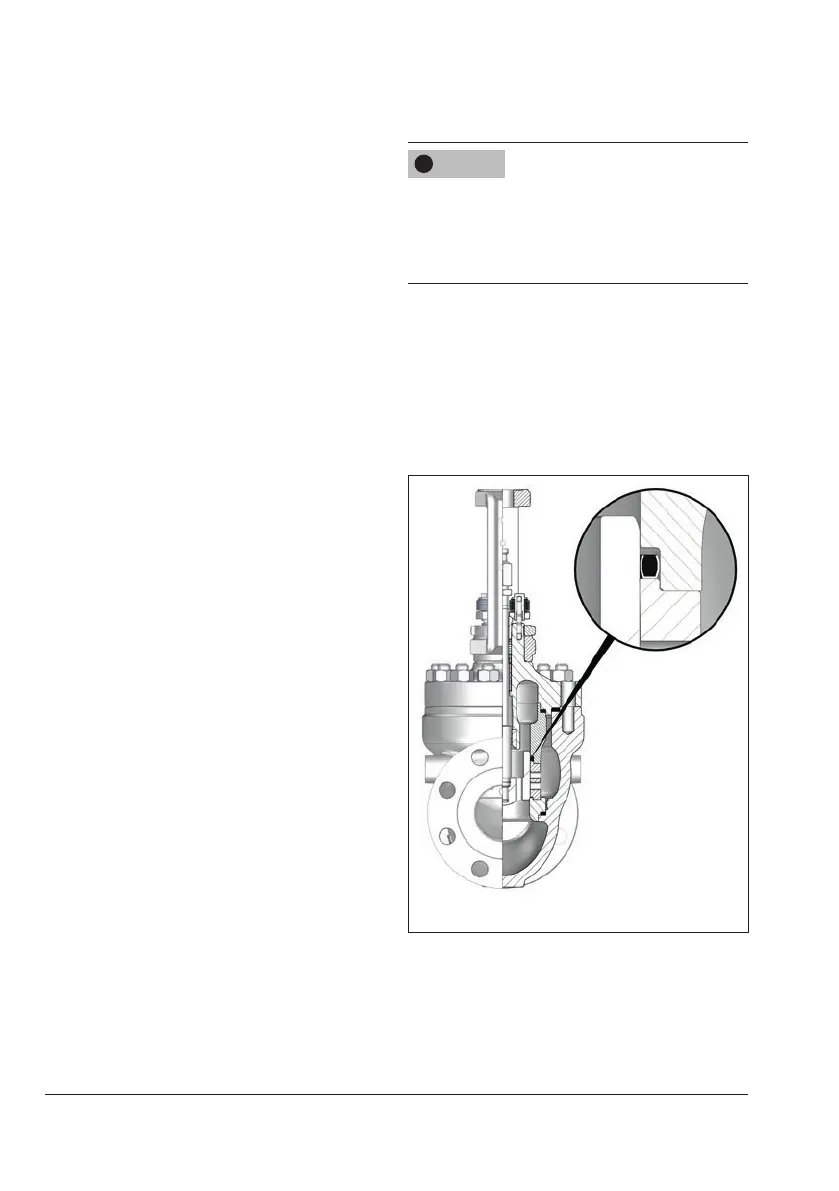

Alignment of the

gasket

Flow to Open (FTO)

Fig.9-7: Alignment of the gasket (45)

NOTICE

!

Loading...

Loading...