8-2 EB 8015 EN

Malfunctions

8.2 Emergency action

Plant operators are responsible for emergen-

cy action to be taken in the plant.

In the event of a valve malfunction:

1. Close the shut-off valves upstream and

downstream of the control valve to stop

the process medium from owing

through the valve.

2. Perform troubleshooting (see Chap-

ter8.1).

3. Rectify those malfunctions that can be

remedied following the information given

in this document. Contact our after-sales

service in all other cases.

Putting the device back into operation after

a malfunction

See the 'Start-up' chapter.

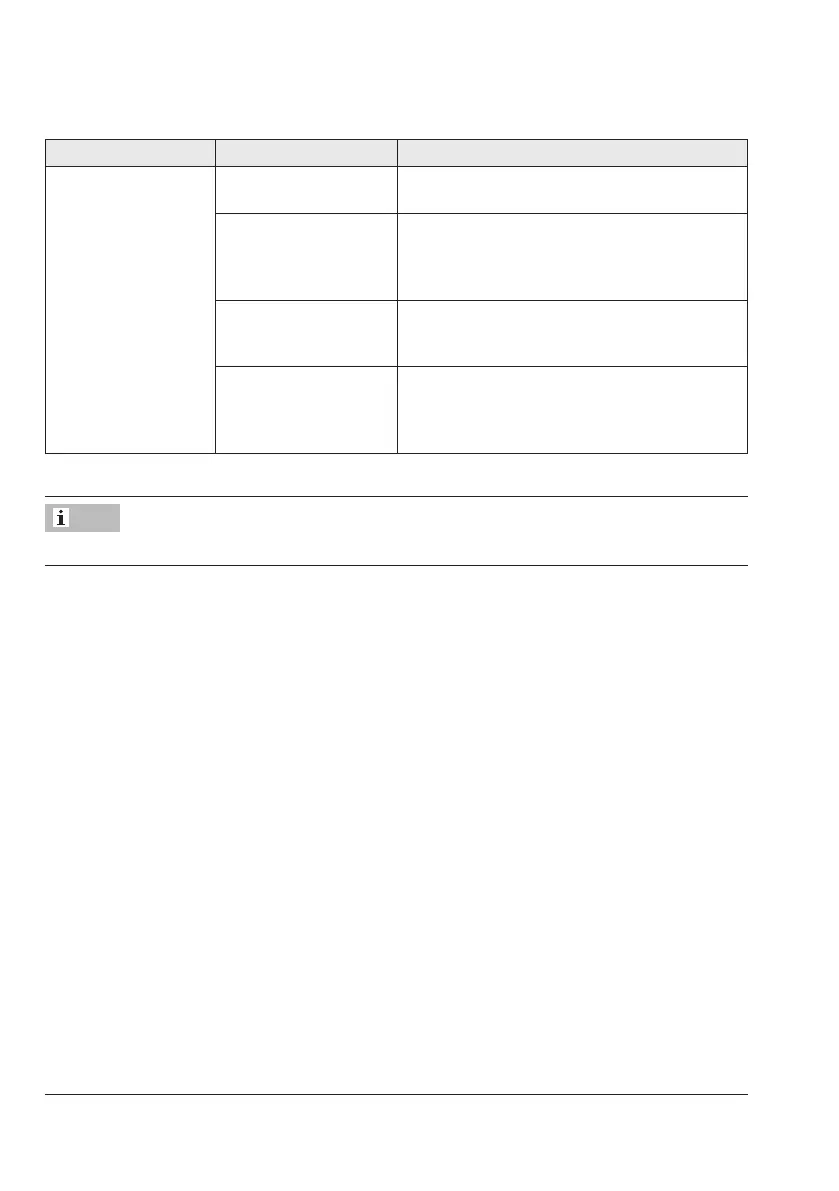

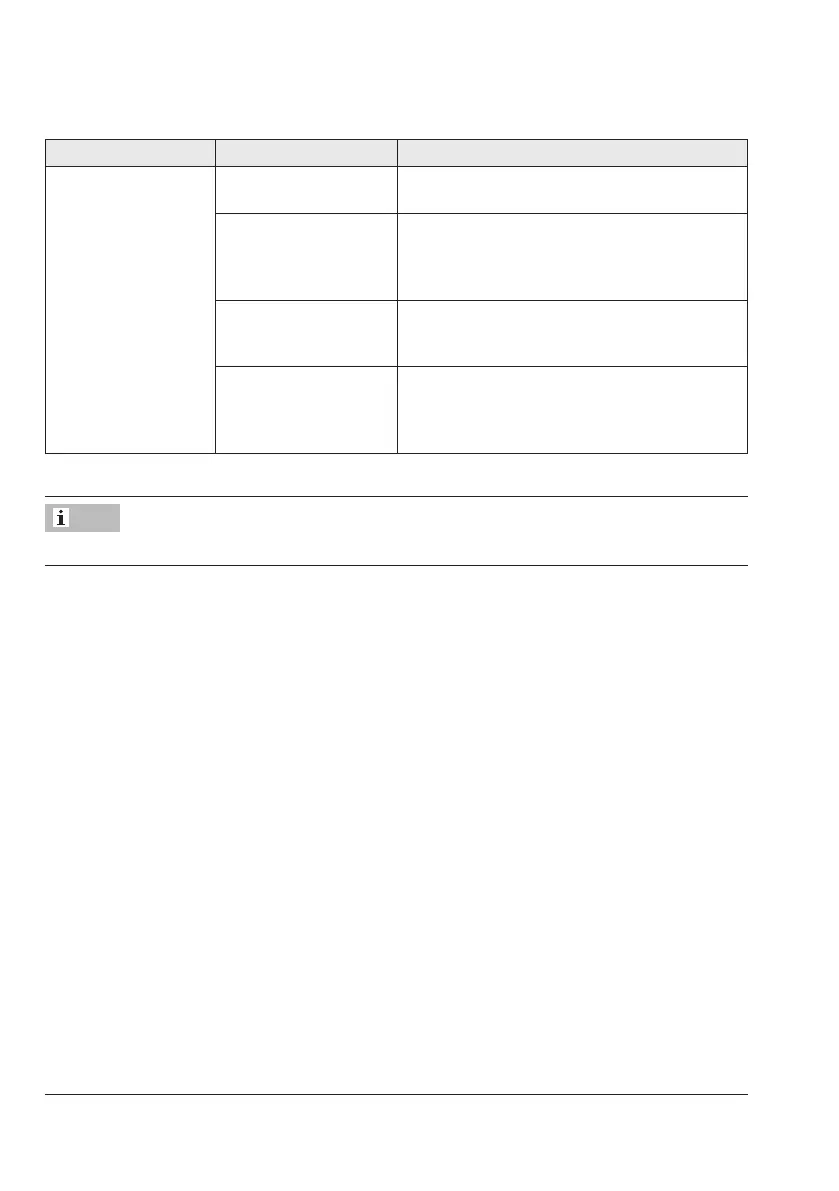

Malfunction Possible reasons Recommended action

The valve leaks to the

atmosphere (fugitive

emissions).

Defective packing Replace packing (see the 'Servicing' chapter) or

contact our after-sales service.

Version with adjustable

packing

1)

: packing not

tightened correctly

Adjust the packing (see section 'Adjusting the

packing' in the 'Installation' chapter> 'Testing the

installed valve'). Contact our after-sales service

when it continues to leak.

Version with bellows

seal: the bellows seal is

defective.

Contact our after-sales service.

Flanged joints loose or

body gaskets worn out

Check anged joints.

Replace gaskets at the anged joints (see the

'Servicing' chapter) or contact our after-sales

service.

1)

See the 'Markings on the device' chapter.

Contact our after-sales service for malfunctions not listed in the table.

Note

Loading...

Loading...