ENGLISH-71

03 INSTALLATION

Optional : Extending the power cable

1. Prepare the following tools.

Tools Spec Shape

Crimping pliers MH-14

Connection sleeve (mm) 20xØ6.5 (HxOD)

Insulation tape Width 19 mm

Contraction tube (mm) 70xØ8.0 (LxOD)

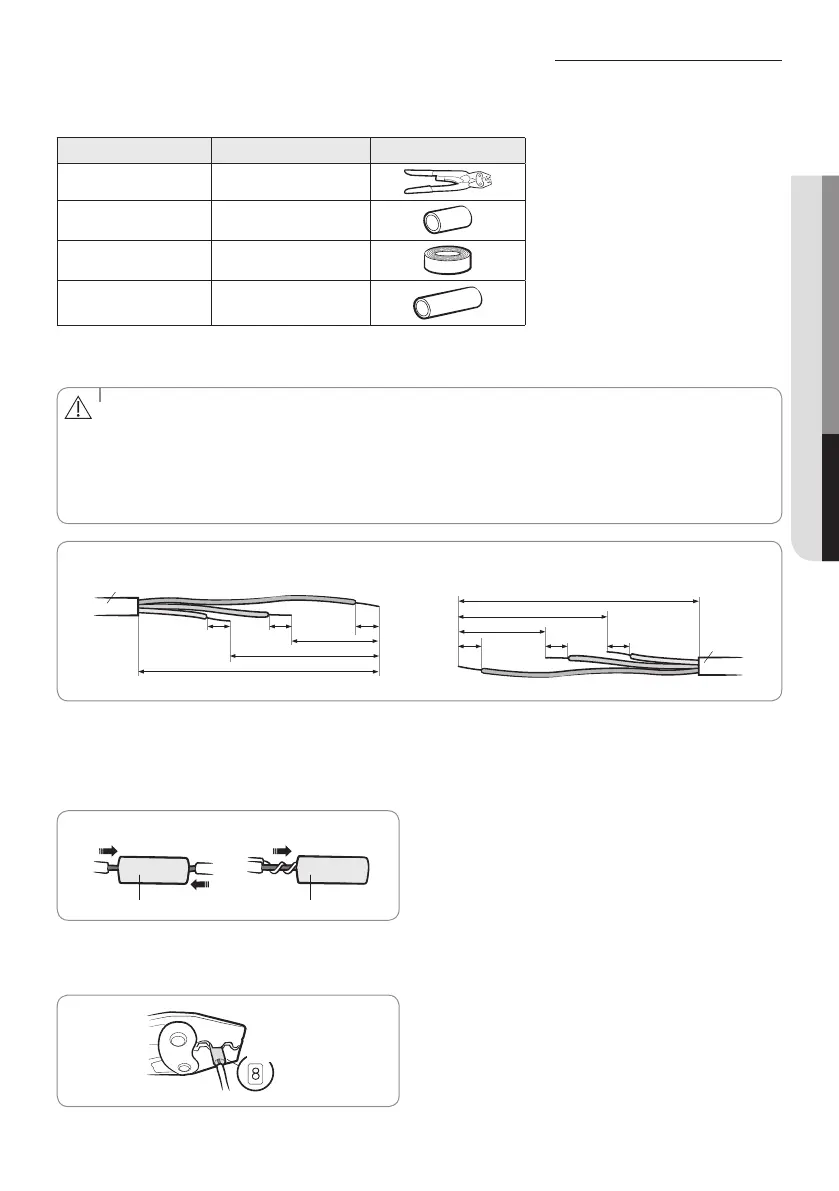

2. As shown in the figure, peel off the shields from the rubber and wire of the power cable.

•

Peel off 20 mm of cable shields from the pre-installed tube.

• For information about the power cable specications for indoor and outdoor units, refer to the installation

manual.

• After peeling o cable wires from the pre-installed tube, insert a contraction tube.

• If cable wires are connected without using connecting sleeves, their contact area becomes reduced, or corrosion

develops on the outer surfaces of the wires (copper wires) over a long time. This may cause an increase of

resistance (reduction of passing current) and consequently may result in a re.

CAUTION

20 20 20

60

120

Power cable

202020

60

120

Pre-installed

tube for the

power cable

(Unit: mm)

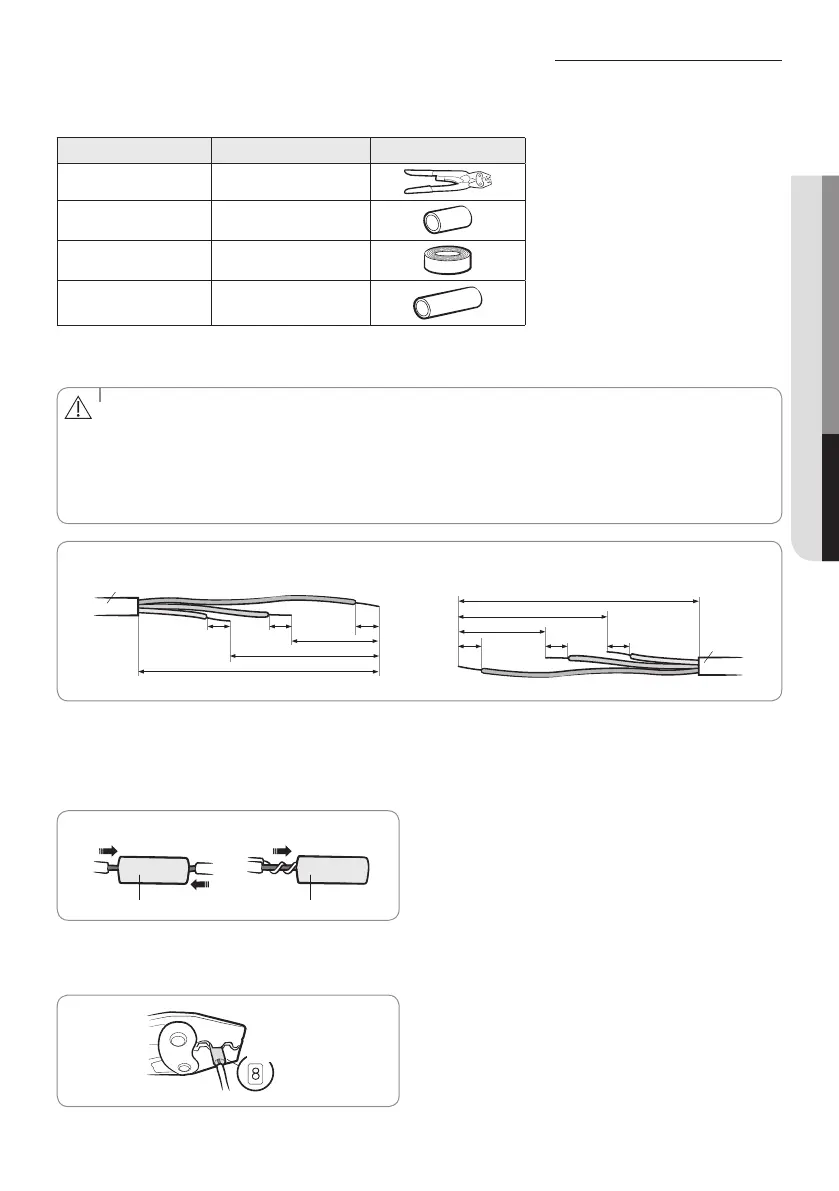

3. Insert both sides of core wire of the power cable into the connection sleeve.

•

Method 1: Push the core wire into the sleeve from both sides.

•

Method 2: Twist the wire cores together and push it into the sleeve.

Method 1 Method 2

Connection sleeve

Connection sleeve

4. Using a crimping tool, compress the two points and flip it over and compress another two points in the same location.

•

The compression dimension should be 8.0.

Compression

dimension

Loading...

Loading...