AE5105/AE5105-3

33

中文

EN

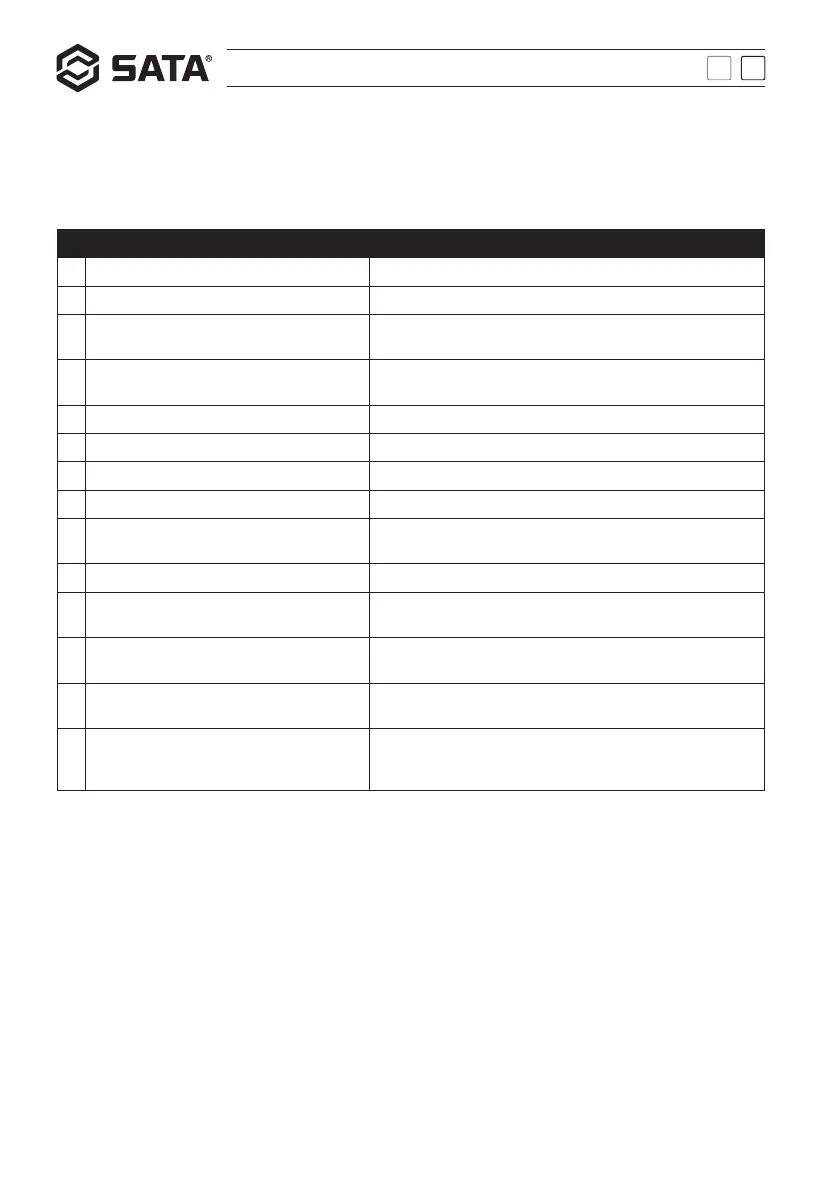

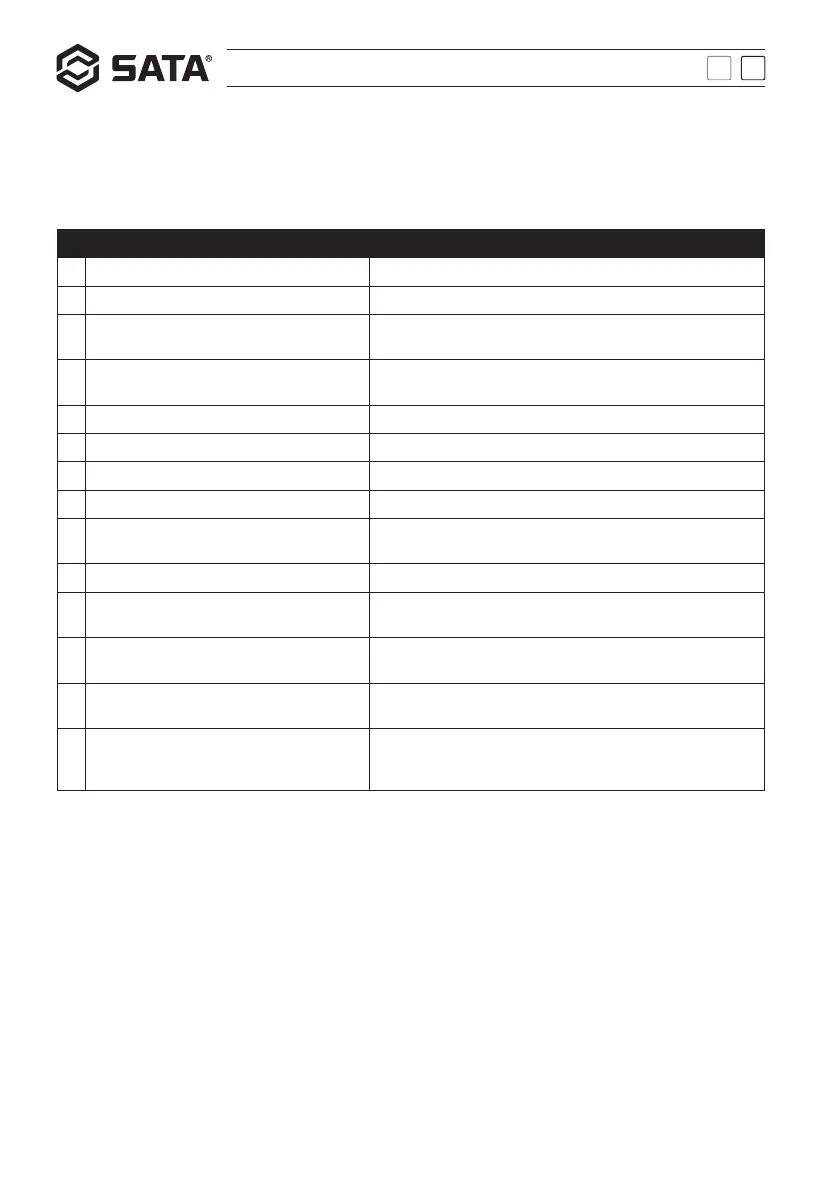

Chapter VI Common Faults

S/N Common Faults Solution

1 Button fails to work Replace the button

2 Contactor fails to operate after energization Replace the contactor

3

The contactor fails to be energized and

operate

Inspect the button and limit switch

4

Oil leakage occurs at the connection of

hydraulic system

Replace the joint or oil pipe

5 Oil leakage occurs in the cylinder

Replace the sealing ring, or replace the cylinder in the worse case

6 The bracket arm teeth do not engage well Adjust the position of the bracket arm teeth

7 Safety rope gets loose Adjust the latch to tighten the safety rope

8 Severe burrs appear on the balance wire rope Replace the wire rope

9

Left and right sliding tables fails to fall to the

same safety position

Adjust the balance wire rope nut to synchronize the sliding

tables

10 Automatic oil return volume drops Replace the oil return valve or lowering flow regulating valve

11

No oil is pumped out when the three-phase

motor is working

The motor rotates reversely. Replace two adjacent power phase

wires (commonly known as live wires)

12

Abnormal sound is heard in the three-phase

motor, or the motor is powerless

Phase loss occurs in the motor, thus inspect the incoming power

wire 380VAC with a multimeter

13

The lowering speed is too low when the lift is

loaded

Inspect if the oil return valve and lowering flow regulating valve

are blocked by foreign matters

14 The lift shakes during operation

Apply grease to the post slideway; inspect if the output pressure

of the hydraulic station is stable enough; inspect the cylinder

piston rod for climbing. (Replace it if any)

Loading...

Loading...