36

2019-03-06 / V1.0

Maintenance

Contactors CT/CU Series – Installation and Maintenance Instructions

Remove the xed contacts

Depending on the contactor type, see Fig. 51 to Fig. 58.

X

Make sure that the latching levers are in the closed

position to avoid damage.

X

Put the upper module upside down on a work-

bench or table on a smooth surface.

Only for contactor types with heat sinks:

X

Remove the 2 xing screws including washers (5)

of each heat sink (6) using a TX20 torx bit.

X

Remove the heat sinks (6) from the xed contacts.

X

Remove the 4 xing screws including washers (1)

of the xed contacts (2) using an appropriate sock-

et wrench:

- 8 mm socket wrench (M5) for CT/CU 11xx/04,

CT/CU 12xx/04

- 10 mm socket wrench (M6) for

CT/CU 11xx/08/10/11, CT/CU 12xx/08/10/11

- 2 of the 4 screws are marked with red

locking varnish which will be destroyed

during that operation.

- 2 of the 4 screws are used to fasten the

cable lug with the copper wire.

X

Keep the screws and washers in a safe place.

X

If necessary, push the cable lugs (3) and the cop-

per wires slightly to the side.

X

Push both xed contacts (2) slightly to the centre

to meet the gap.

X

Remove the xed contacts (2) one by one.

1

1

2

3

3

2

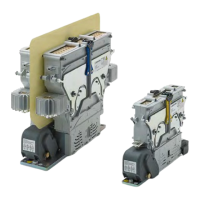

Fig. 51: CT/CU 1115/04: Remove the xed contacts

1

2

1

2

3

3

Fig. 52: CT/CU 1130/04, 1115/08/10, 1130/08/10: Remove the

xed contacts

5

6

5

6

Fig. 53: CT/CU 1115/11, 1130/11: Remove the heat sinks

1

2

1

2

3

3

Fig. 54: CT/CU 1115/11, 1130/11: Remove the xed contacts

Loading...

Loading...