Initial Setup and Use

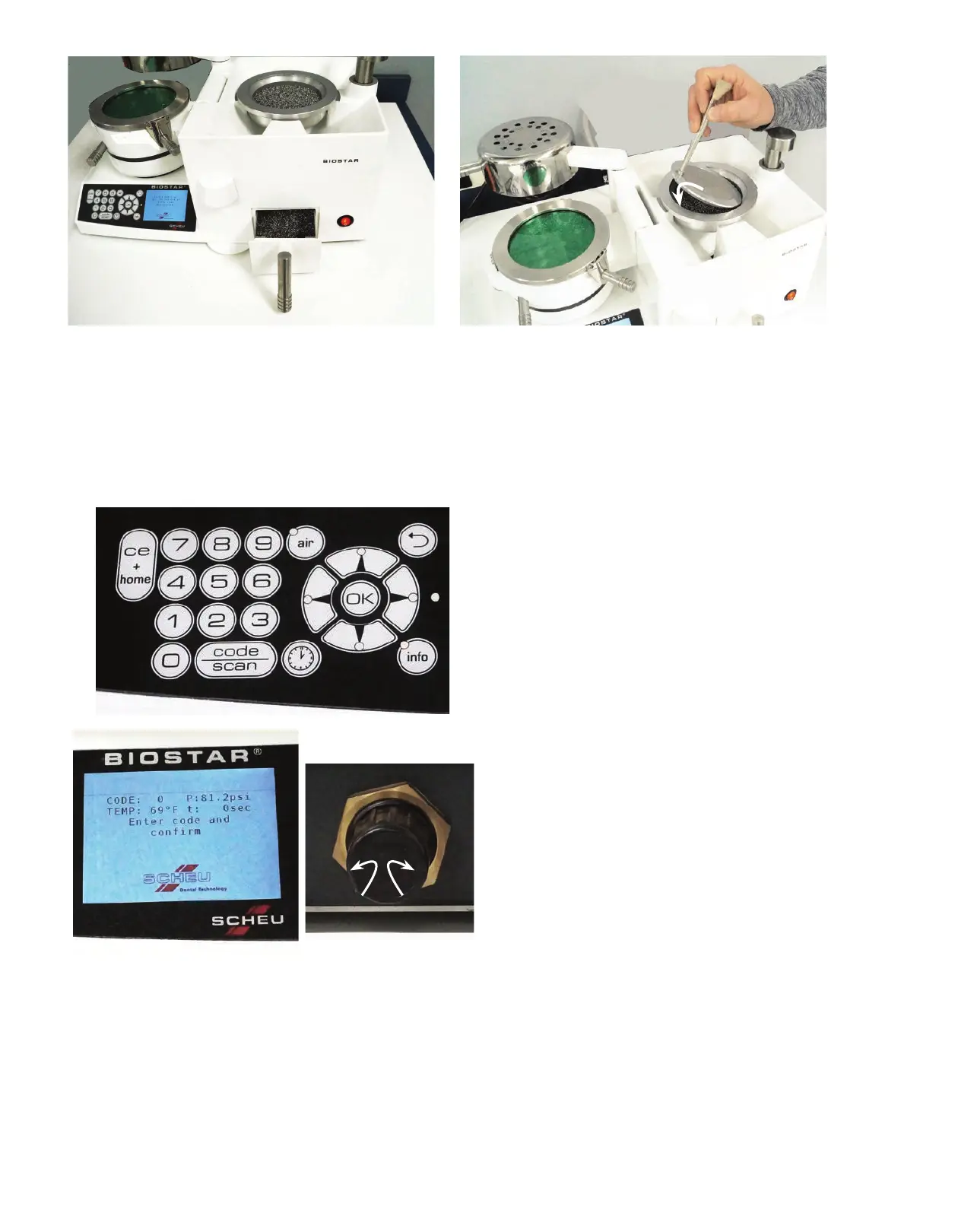

5. With pellets provided, ll cup (E) half full with pellets.

6. Pour remaining pellets in the pellet drawer (F) and close the drawer ush to the machine.

7. Place the platform on the inner lip of the pellet cup (white arrow), with the pellet level half full.

IMPORTANT: Make sure the inner lip of the cup is clear of pellets.

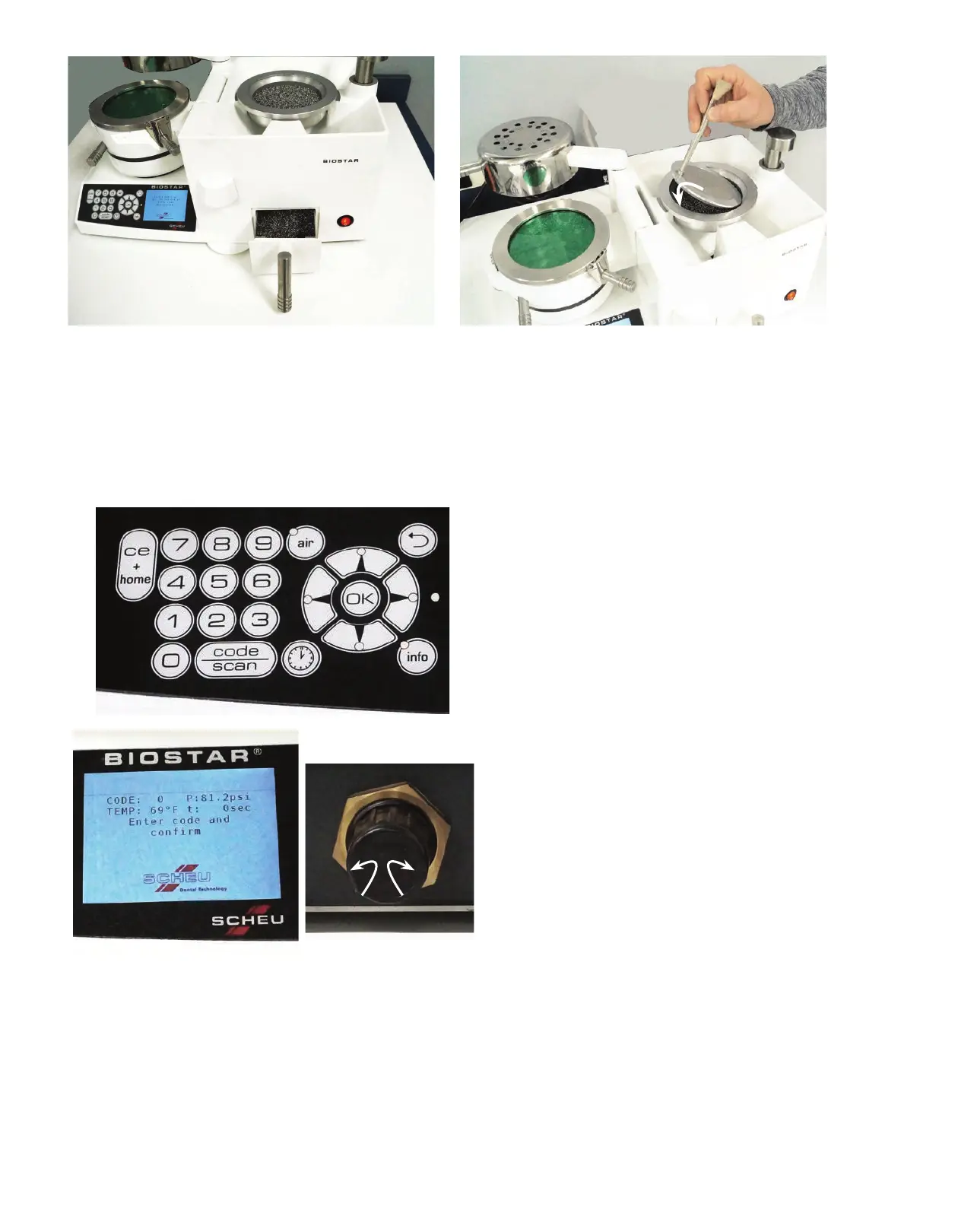

8. Working pressure of 80psi is pre-set in the

machine. With the power button in the ‘ON’

position, press the CODE/SCAN button (A).

The current pressure will show on the LCD

display. Conrm or adjust the Biostar air

pressure (B) if needed.

Reach behind the machine and release the

locking cap (C) on the regulator by pulling it

outward. Set the pressure by turning the regulator

dial on the back of the machine clockwise to

increase the pressure, counterclockwise to

decrease (D). The LCD display will show the

change in pressure (E). Once the desired pressure

is set, lock the regulator by pushing the cap in

towards the machine.

Maximum pressure can only equal what the

main line is capable of supplying.

• Reminder: DO NOT use material thicker than 5mm within the clamping mechanism. This may

cause the Biostar to malfunction while pressure is in the chamber, and damage the internal

chamber springs.

• ALWAYS wear safety glasses when using this machine and during all fabrication procedures.

E

F

B

A

E

C

D

-

+

Loading...

Loading...