Copyright © 2021 Axxiom Manufacturing, Inc.

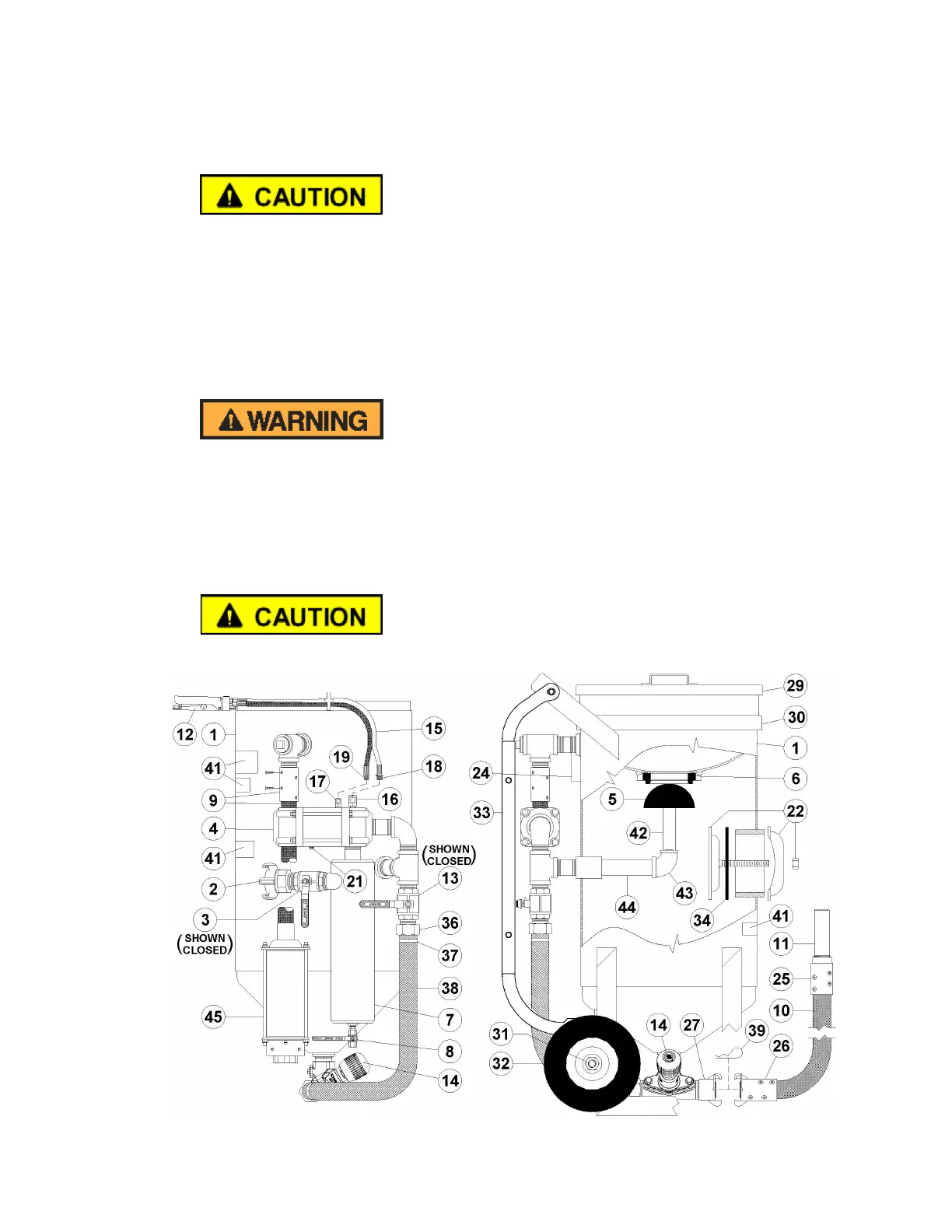

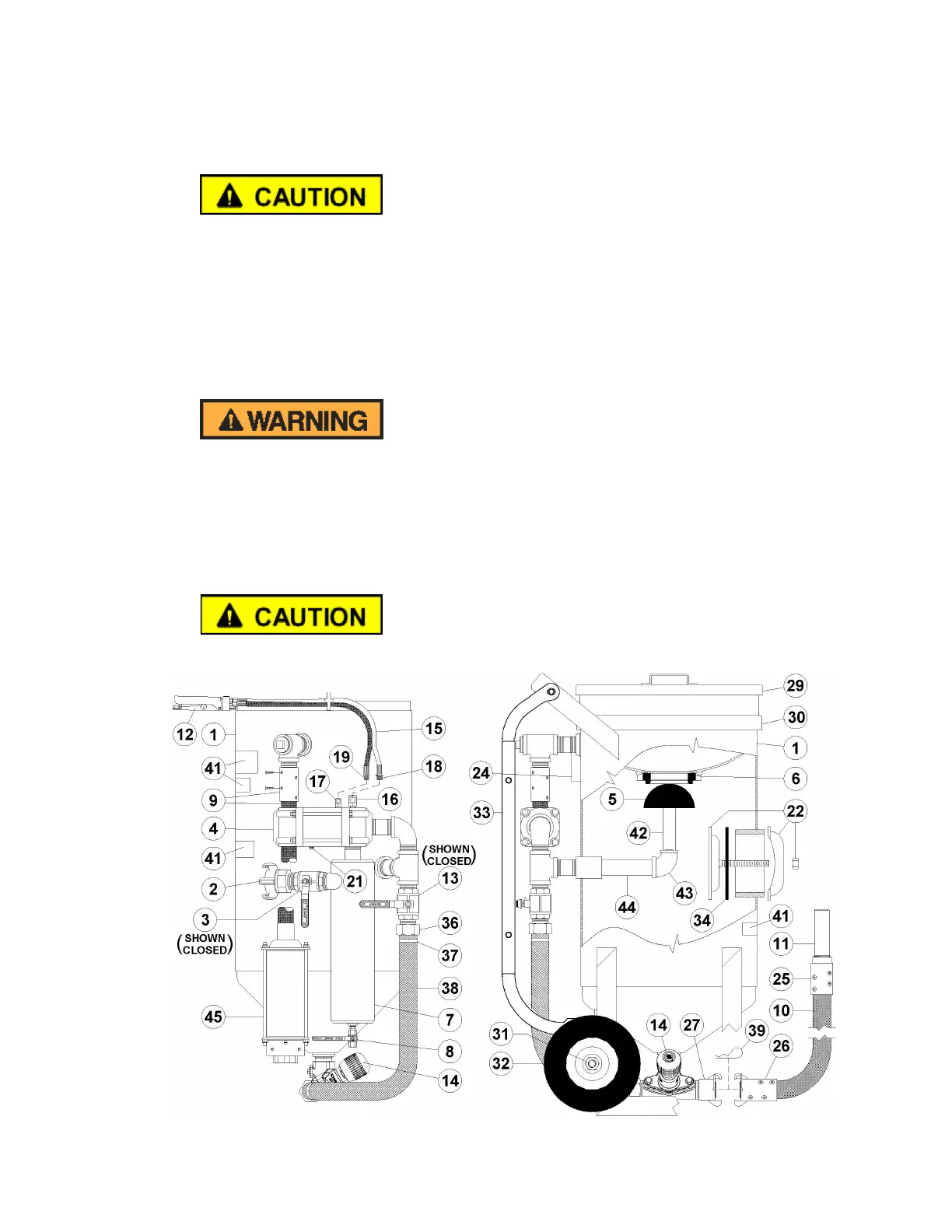

7.3 Ending the Blast Operation (See Figure 7.3)

7.3.1. Close the air inlet ball valve (#3). The ball valve is closed when the handle is fully

turned to the position shown in Figure 7.3 (handle perpendicular to body). The handle

tab will bottom against the ball valve body in the closed position.

Do not turn off the air compressor and allow the abrasive blaster air pressure to back

flow through the air supply system. Back flow will carry abrasive into the moisture trap

(#7) and contaminate the controls.

7.3.2. Completely open the drain ball valve (#8) at the bottom of the moisture trap (#7) to

allow all the accumulated moisture to be drained out. Close the ball valve after draining.

7.3.3. Completely depressurize the abrasive blast vessel (#1). MV3 Valve blasters

automatically depressurize when the deadman valve (#12) is released to stop blasting.

See Section 6.2 for blowdown procedure.

Airborne particles and loud noise hazard from the blowdown exhaust air can cause

serious injury and loss of hearing. Wear approved eye and ear protection. Stay clear of

blowdown air path. DO NOT place hands or other body parts in the blowdown air path.

Make sure no personnel are in the blowdown air path.

7.3.4. For long periods of non-usage remove remaining blast abrasive from blast vessel to

minimize moisture contamination. Replace lid (#29) to prevent debris from entering

blast vessel (#1).

Steel abrasive left inside the blast vessel can be contaminated by moisture and solidify

inside causing costly damage.

Figure 7.3 – MV3 Valve Abrasive Blaster with pneumatic blast controls

Loading...

Loading...