Copyright © 2021 Axxiom Manufacturing, Inc.

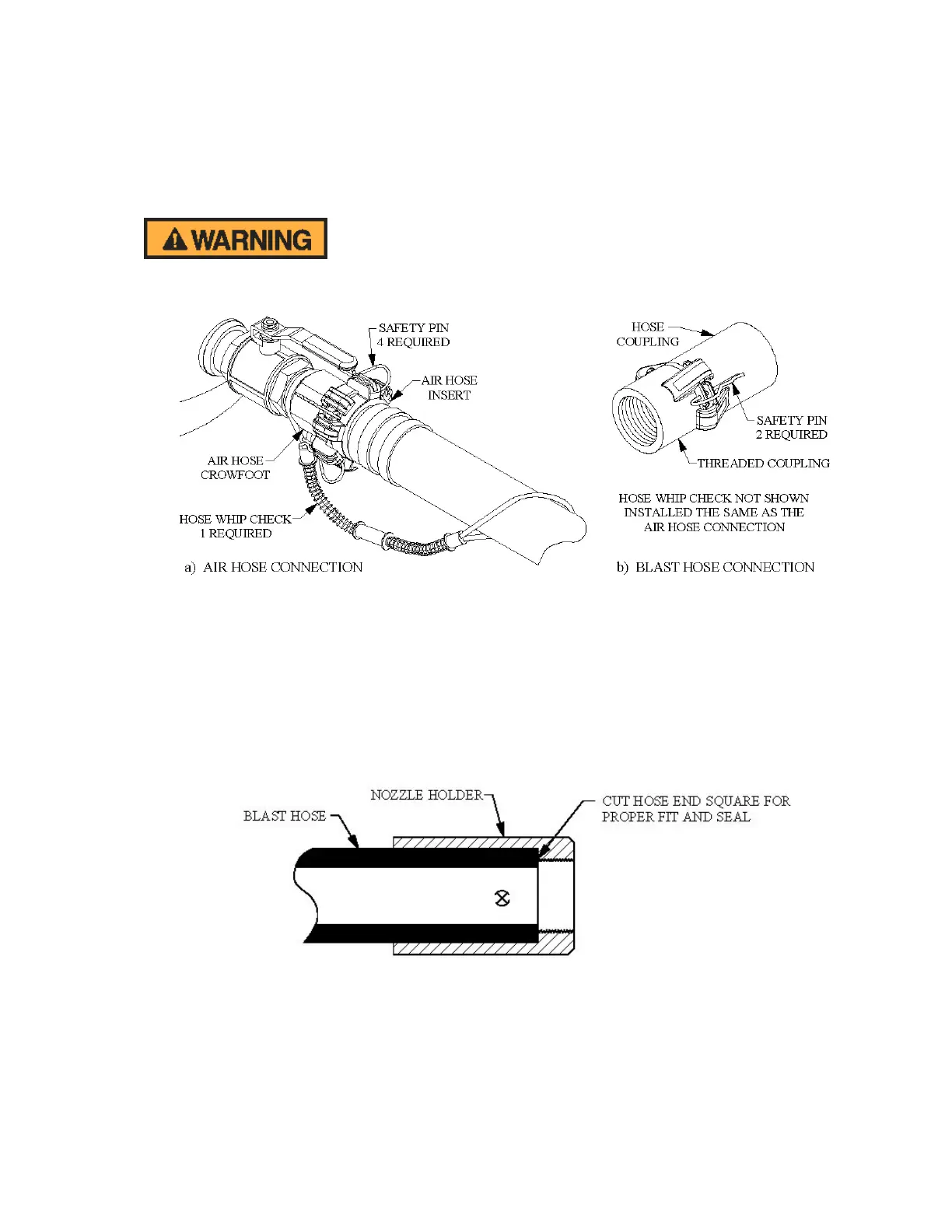

8.7. Blast and Air Hose Couplings: All air hose, blast hose, and threaded couplings have two pin

holes that align when connected. To protect against accidental hose disconnections safety pins

must be installed through these holes. Each hose connection must also include a hose whip

check that will hold the hose if there is an accidental disconnection. Connect one loop to each

side of the connection and stretch out as shown in Figure 8.2 below. Check hose connections

daily and replace missing or damaged pins and whip checks.

Failure to install safety pins on all air and blast hose couplings can result in hose disconnects

and could result in serious injury or death.

Figure 8.2 – Hose Connection Disconnect Protection

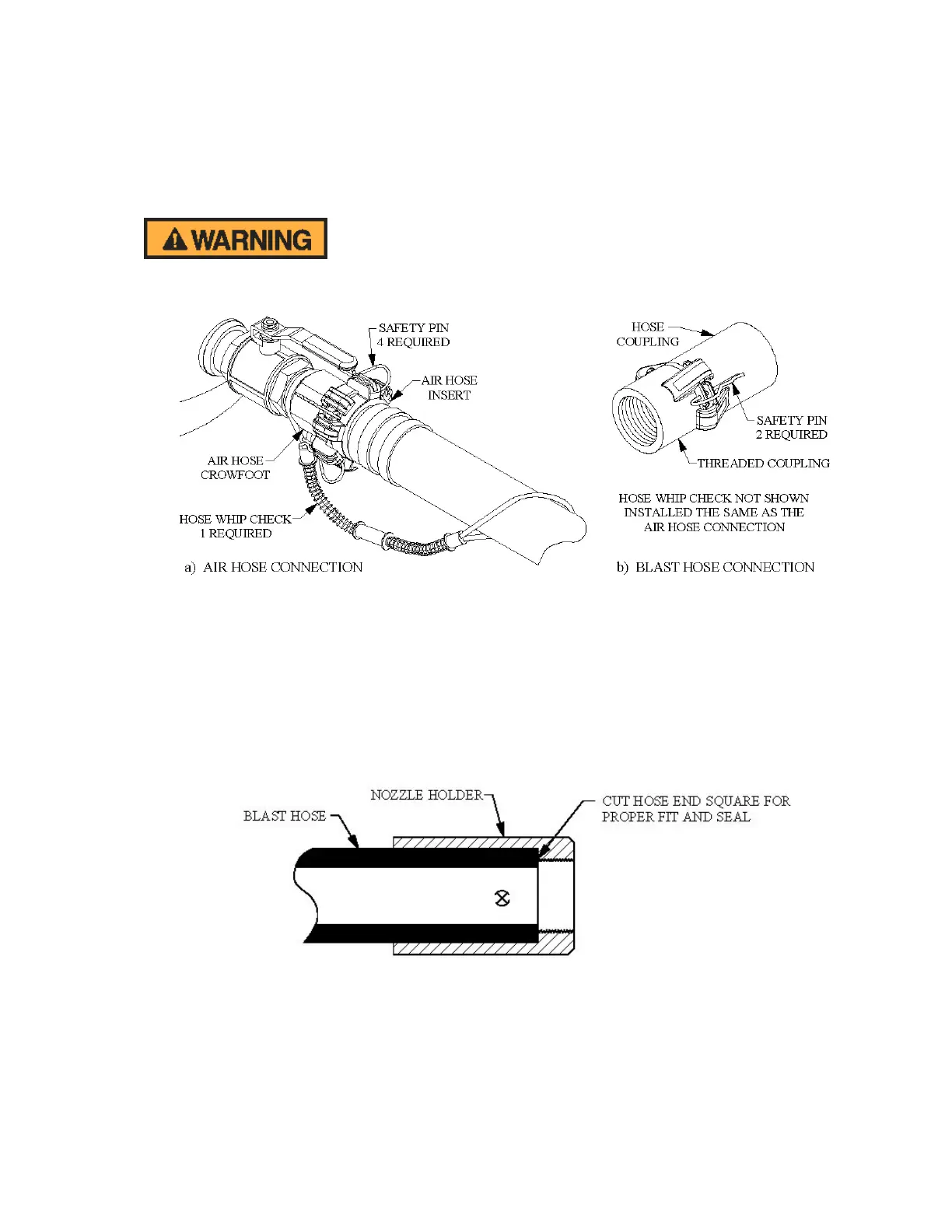

8.8. Blast and Air Hose Gaskets: All air hose, blast hose, and threaded couplings have gaskets that

seal the connection. To reduce loss of air pressure and/or premature abrasive wear replace these

gaskets when leaks are found. Inspect the couplings daily for leaks and wear. Replace gaskets

when visible wear or leaks are found. When installing or replacing hose couplings cut the hose

end square for secure fit (see Figure 8.3). To ensure proper coupling connection always use

fittings that are the same brand. See the drawings and part lists in Section 9.0.

Figure 8.3 – Hose End Fit up

8.9. Blast Nozzle: Remove the blast nozzle daily and check the jacket and thread condition. Check

nozzle throat diameter. An over-sized throat diameter reduces blast efficiency. Replace the blast

nozzle if worn or damaged.

Loading...

Loading...