Copyright © 2021 Axxiom Manufacturing, Inc.

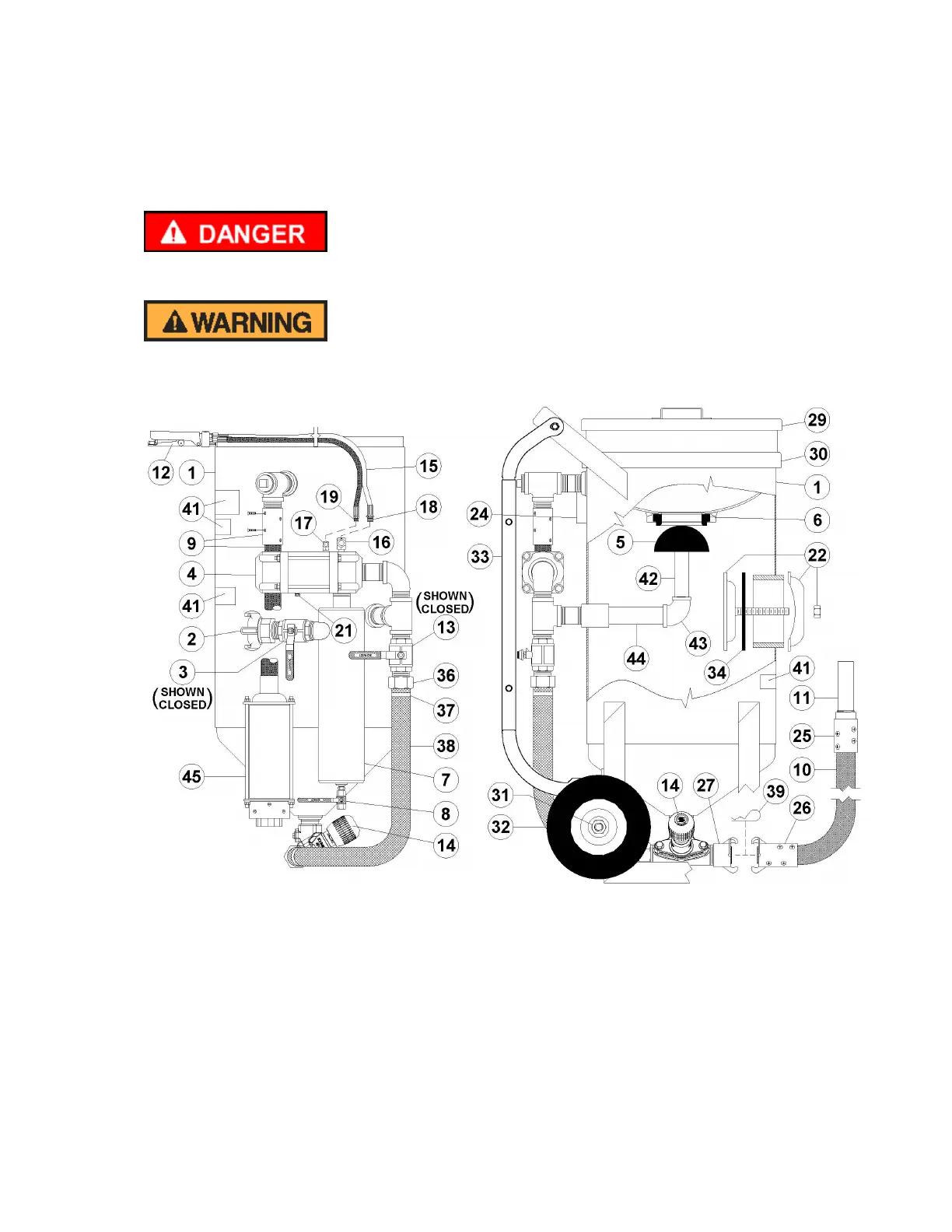

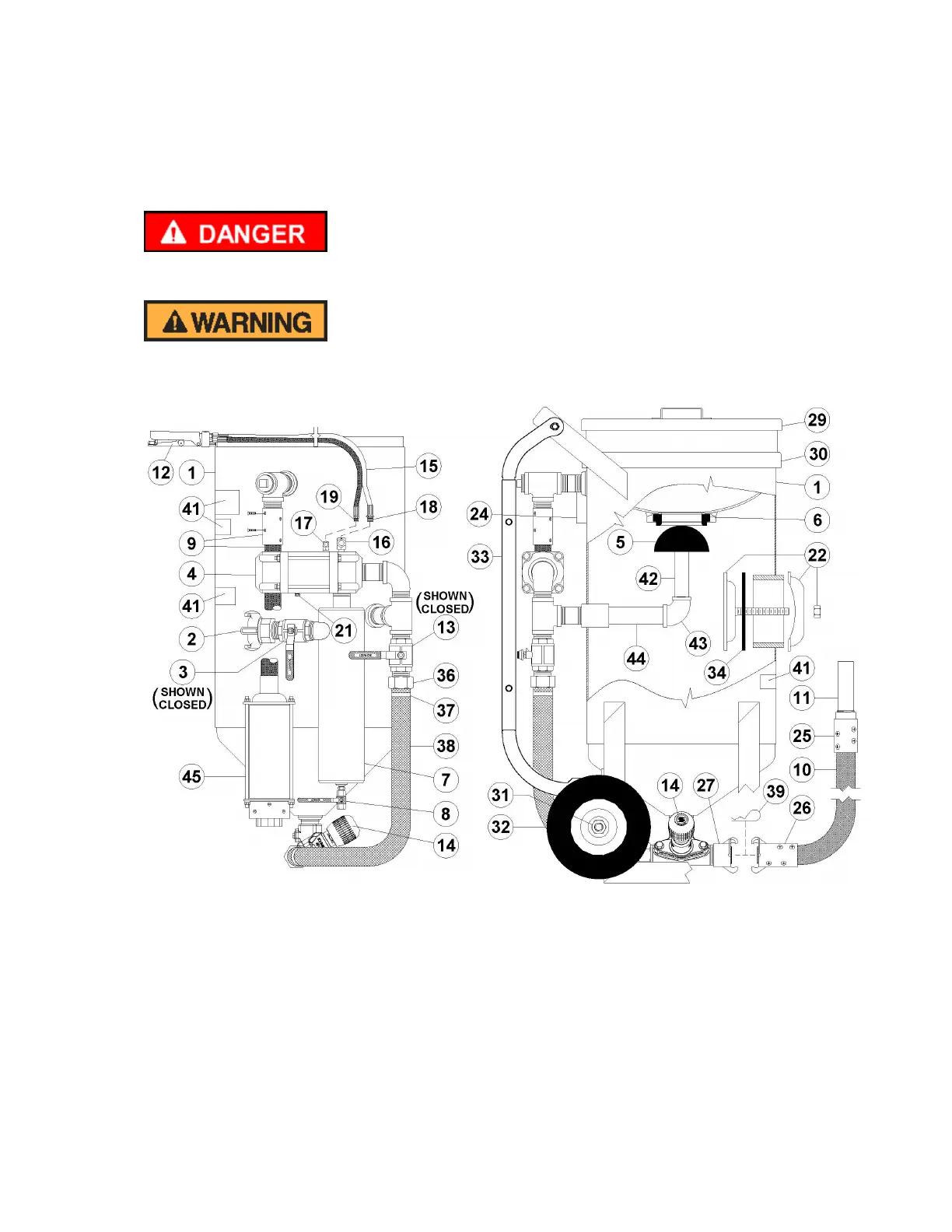

8.10. Valves: MV3 Valve, ComboValve®, control valves, and deadman valves should be

disassembled and inspected quarterly, or more frequently if heavily used. Ball valves should

open and close without difficulty and should not leak air. Repair or replace any component that

shows signs of damage. Replace parts as needed with Schmidt® original factory replacement

parts furnished by an authorized Schmidt distributor. Refer to valve drawings in Section 9.0 and

specific valve maintenance manual.

Depressurize vessel before performing any maintenance. See Section 6.2. Removing

components with the abrasive blaster pressurized will result in serious injury or death.

Use of replacement components that are not Schmidt® original factory replacement parts may

result in equipment failure which can result in serious personal injury.

Figure 8.4 – MV3 Valve Abrasive Blaster with pneumatic blast controls

8.11. ComboValve® Blowdown Hose: The blowdown hose (#9) that passes through the

ComboValve (#4) is a 3/4" blast hose. Abrasive carry-over will thin the blowdown hose wall

and eventually wear a hole through the hose. Excessive thinning will prevent the ComboValve

pinch ram from sealing the exhaust flow and result in equipment malfunction. The abrasive

carry-over will also wear the pipe fittings upstream. See Figure 8.4. Depressurize the abrasive

blaster per Section 6.2 and check hose condition weekly. Replace as needed. When replacing

the blowdown hose (#9) also replace the pipe fittings upstream of the valve. These fittings are

the 1-1/4” x 3” VBS II Restrictor, 1-1/4” tee, and the 1-1/4” pipe plug (see Figure 8.4).

Loading...

Loading...