Copyright © 2021 Axxiom Manufacturing, Inc.

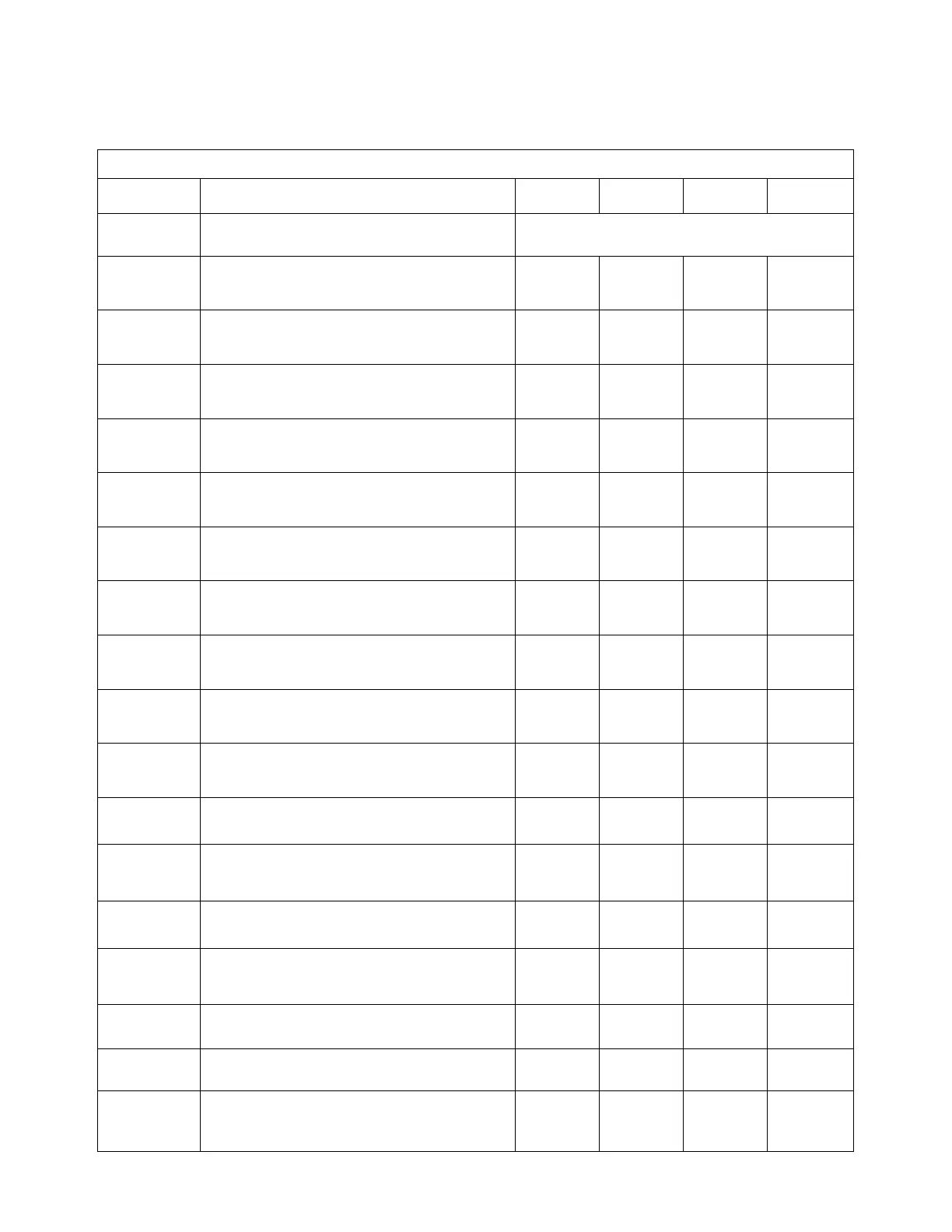

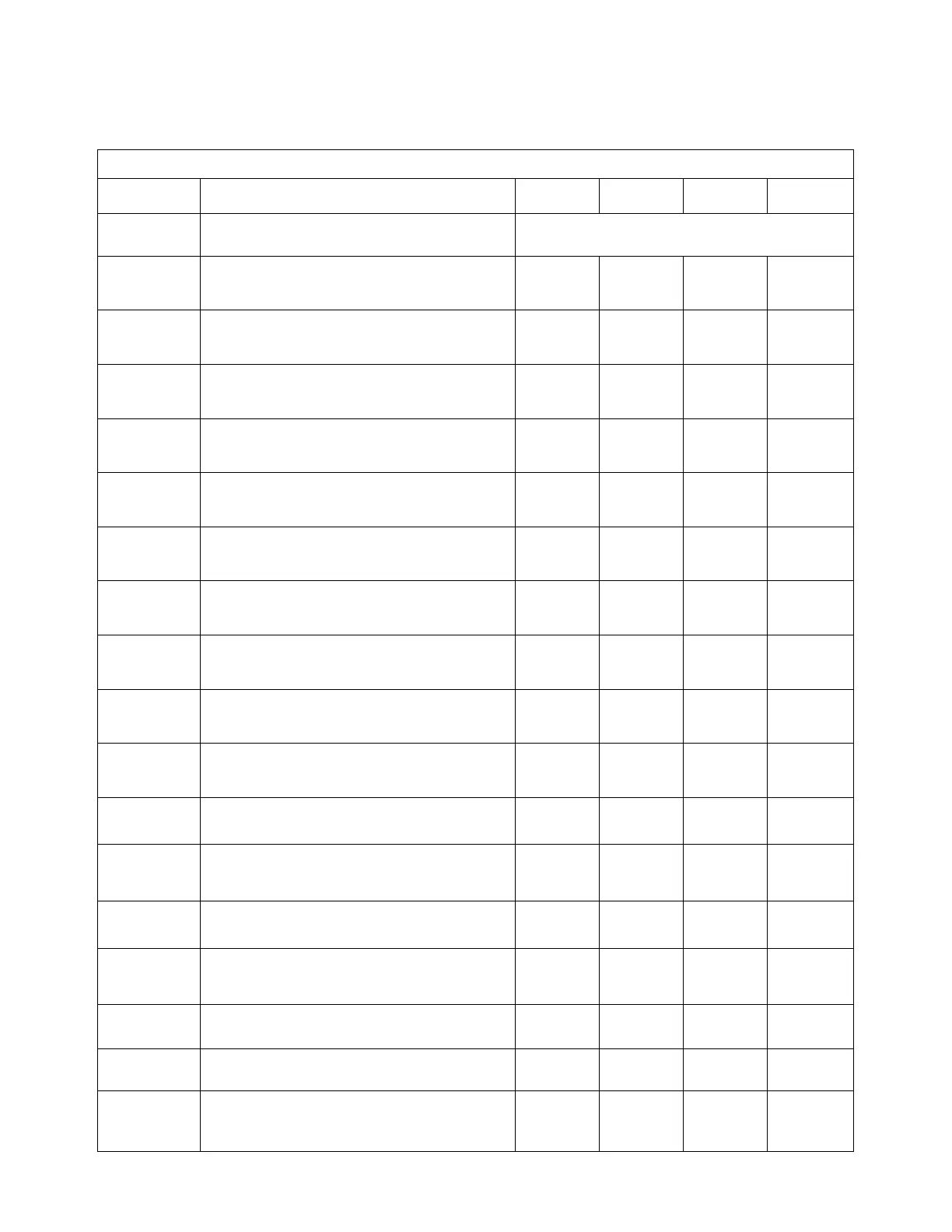

8.17. Maintenance Schedule Quick Reference Chart

Note: The below schedule is the minimum requirements for inspection and maintenance; however, the

equipment should be inspected and serviced immediately if abnormal operation is detected.

SMALL POT ABRASIVE BLASTER MAINTENANCE SCHEDULE

Item Maintenance Required Daily Weekly Monthly Quarterly

Vessel

See Section 8.1

As required by state law and/or local authorities

Blaster

Vessel

Check for exterior damage

(corrosion, dents, bulges).

X

Blaster

Vessel

Check for interior wear, corrosion, & pitting.

Check internal piping for wear or damage.

X

Popup

Check sealing surfaces, alignment and

gasket to popup gap.

X

Blast & Air

Hoses

Check air & blast hoses for soft spots,

wear, cracks, or air leaks

X

Control

Check control air hoses for soft spots,

wear, cracks, or air leaks

X

&

Check pipe & pipe fittings for

wear, cracks, or air leaks

X

Control

Check wiring for bare spots,

fraying, cuts, or cracks

X

Hose

and whip checks

X

Coupling

Check for leaks at the air, blast,

and threaded hose coupling gaskets

X

Blast Nozzle

Check blast nozzle threads

and jacket for wear, damage, or air leaks.

X

Valves

Disassemble, inspect, and lubricate. Check operation.

See Section 8.10

X

Blowdown

Check blowdown hose for wear or thinning.

Check pipe tee, plug, and nipple for wear.

X

VBS II

System

Check VBS II internal components for wear.

See Sections 9.10 and 8.12.

X

Protective

Check for presence and condition of all

personal protective equipment.

See Sections 3.10 and 8.13.

X

Decals

Check presence and condition of warning decals.

See Sections 0.0 and 8.14

X

Check condition of gasket and sealing surfaces

See Sections 6.3 and 8.15.

X

Moisture

Separator &

Strainer

Fully open moisture separator drain ball valve and

strainer petcock to purge moisture and debris.

See Section 8.16.

X

Loading...

Loading...