Copyright

This manual remains the copyrighted property of SCHUNK GmbH & Co. KG. It

is solely supplied to our customers and operators of our products and forms

part of the product. This documentation may not be duplicated or made ac-

cessible to third parties, in particular competitive companies, without our

prior permission.

Technical changes

We reserve the right to make alterations for the purpose of technical im-

provement.

Document number:1005274

Edition:01.00|23/01/2017|de - en

© SCHUNK GmbH & Co. KG

All rights reserved.

1Intended use

If the gripper finger has some clearance, if the positioning is incorrect or if

movement is asymmetrical, the gripper finger will need to be changed. Ex-

pansion cracks or enlargement of the guide groove are the most frequent

indicators of a defective gripper finger. The cause for this defect is often a

collision. After a collision, the piston rod may also be damaged.

2Scope of Delivery

Designation GWB

34 44 54 64 80

Gripper fingers [pcs.] 1 1 1 1 1

Set-screw [pcs.] 2 2 2 2 2

Cylindrical pin [pcs.] 1 1 1 1 1

Switching lug [pcs.] 1 1 1 1 1

Designation GWB

34 44 54 64 80

Bracket for NHS [pcs.] 1 1 1 1 1

Screw [pcs.] 1 1 1 1 2

3Applicable documents

• Catalog data sheet of the product *

• Assembly and operating manual of the product *

The documents marked with an asterisk (*) can be downloaded on our

homepage www.schunk.com.

4Notes on particular risks

WARNING

Risk of injury due to sudden movements!

If the energy supply is switched on or if residual energy is still present in the

system, this can cause components to move unexpectedly, which may res-

ult in serious injuries.

• Switch off energy supply and secure against re-connection.

• Ensure that no residual energy remains in the system.

5Tools/auxiliary tools

• Hexagon socket wrench

• Drift punch

• Hammer

6Recommended lubricants

not required

7Tightening torque

not required

8Threadlocker

If not stated otherwise, screws can be secured using Loctite 243 or a similar

adhesive.

9Changing the gripper finger

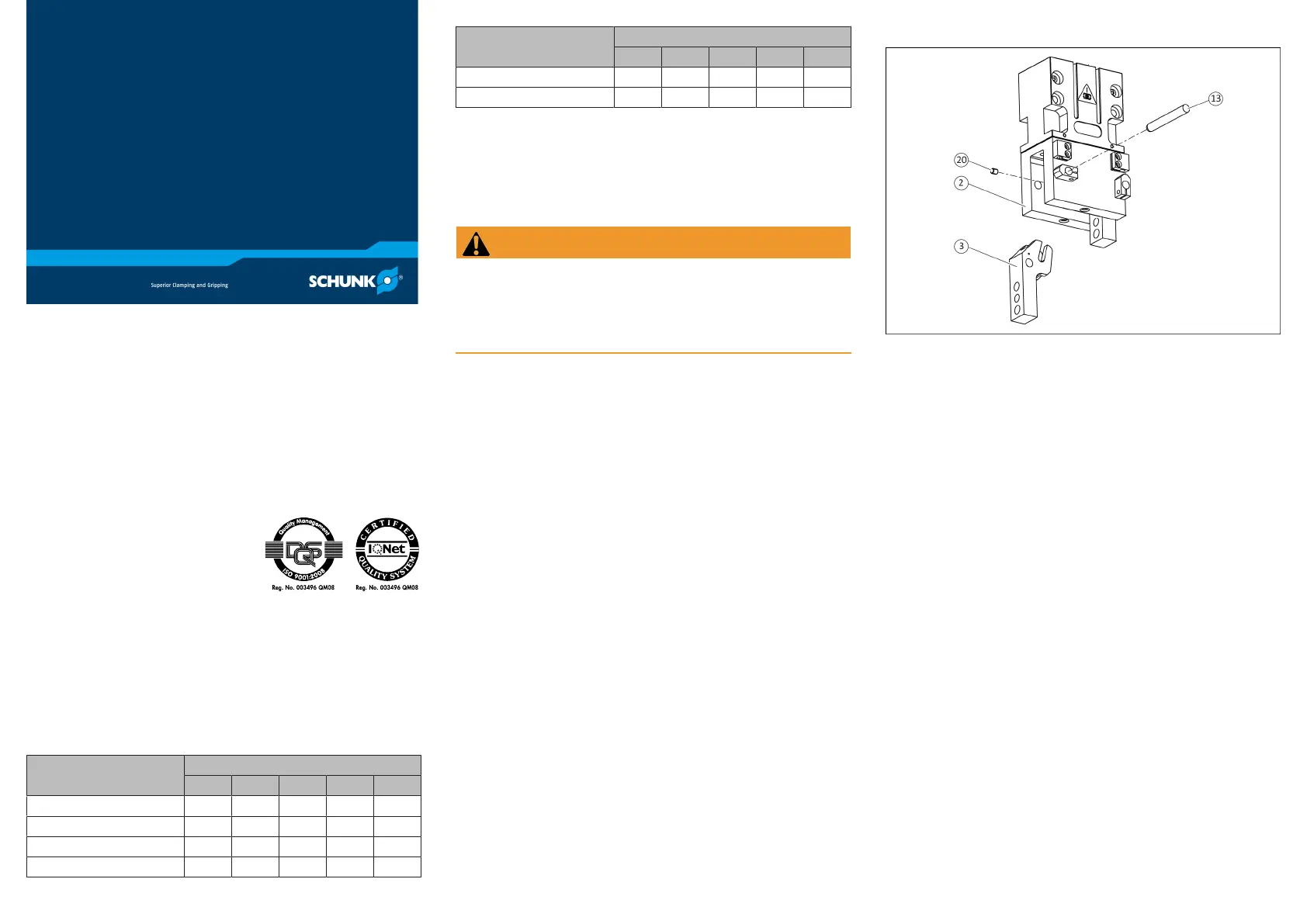

Dismantling

Ø Remove all compressed air lines.

Ø Disassemble gripper from the machine/automated system.

Ø Connect compressed air line to the gripper and put gripper finger (3) into

"opened" position.

Ø Unscrew set-screw (20) from the gripper finger (3).

Ø Push cylinder pin (13) out of the housing (2).

Ø Remove the gripper finger (3) from the housing (2).

Assembly

When assembling, use the parts from the spare part package.

Ø Clean all parts thoroughly, check for damage and wear.

Ø Insert the gripper finger (3) into the housing (2).

Ø NOTICE!Make sure the installation position of the cylinder pin (13) is

correct.

Insert the cylinder pin (13) into the housing (2) in such a way that the

groove is over the bore hole for the set-screw (20).

Ø Screw the set-screw (20) into the gripper finger (3).

Ø Remove the compressed air line.

Ø Assemble gripper on the machine/automated system.

Ø Secure all compressed air lines.

GWB34-80

Gripper finger spare parts

package

Repair Instructions

SCHUNK GmbH & Co. KG | Spann- und Greiftechnik

D-74348 Lauffen/Neckar | Bahnhofstr. 106 – 134

Tel. +49-7133-103-0 | Fax +49-7133-103-2399

info@de.schunk.com | www.schunk.com

Loading...

Loading...